In a world increasingly focused on sustainability, the electronics industry faces a pressing challenge: how can we move beyond traditional recycling to create a truly sustainable future for printed circuit boards (PCBs)? Specifically, when it comes to flexible PCBs (flex PCBs), redesigning them for a circular lifecycle is key to reducing waste, conserving resources, and supporting a closed-loop PCB system. This blog explores innovative strategies for sustainable electronics redesign, focusing on circular economy PCBs, PCB lifecycle management, and the integration of reusable component PCBs.

At its core, a circular lifecycle for flex PCBs means designing products that can be reused, repaired, or repurposed at the end of their life, minimizing waste and maximizing resource efficiency. Let’s dive into how this can be achieved through thoughtful design, material choices, and manufacturing practices tailored for sustainability.

What Is a Circular Economy for PCBs?

A circular economy in the context of PCBs refers to a system where products are designed to stay in use for as long as possible. Unlike the traditional linear model of "make, use, dispose," a circular economy focuses on creating a closed-loop PCB system. This means that at the end of a product's life, its components and materials are recovered and reused in new products, reducing the need for virgin resources and minimizing electronic waste (e-waste).

For flex PCBs, which are widely used in compact and lightweight devices like smartphones, wearables, and medical equipment, adopting a circular economy approach is both a challenge and an opportunity. These boards are often made from complex materials like polyimide films and copper laminates, which can be difficult to recycle with conventional methods. However, by rethinking design and manufacturing processes, we can pave the way for sustainable electronics redesign.

Why Focus on Flex PCBs for Circular Lifecycle Management?

Flex PCBs are unique due to their lightweight, thin, and bendable nature, making them essential for modern electronics. However, their complex construction poses significant hurdles for traditional recycling. Most recycling processes focus on recovering precious metals like gold and copper, but the plastic substrates and adhesives in flex PCBs often end up as waste. This is why PCB lifecycle management must prioritize redesign over mere recycling.

By focusing on circular economy PCBs, manufacturers can address these challenges. For instance, designing flex PCBs with modular components or standardized layouts can make disassembly and reuse easier. Additionally, using eco-friendly materials can reduce the environmental impact during production and disposal. According to recent industry insights, the global circular economy market is expected to grow significantly by 2034, reflecting a strong push toward sustainability across sectors, including electronics.

Key Strategies for Redesigning Flex PCBs for a Circular Lifecycle

Creating a closed-loop PCB system requires a multi-faceted approach. Below are actionable strategies to redesign flex PCBs for sustainability, focusing on material selection, modular design, and end-of-life recovery.

1. Material Selection for Sustainability

The choice of materials in flex PCBs plays a critical role in their environmental impact. Traditional flex PCBs use polyimide films, which are durable but challenging to recycle due to their chemical composition. To support a circular economy for PCBs, manufacturers can explore alternative substrates that are biodegradable or easier to break down.

For example, research into paper-based PCBs is gaining traction. These substrates, while not yet as durable as polyimide, offer a promising avenue for reducing waste. Additionally, using lead-free solders and halogen-free laminates can minimize toxic byproducts during disposal, aligning with sustainable electronics redesign principles.

2. Modular Design for Reusable Component PCBs

One of the most effective ways to achieve a closed-loop PCB system is through modular design. This approach involves creating flex PCBs with standardized, interchangeable components that can be easily removed and reused in other devices. For instance, connectors, sensors, and microcontrollers can be designed as plug-and-play modules rather than being permanently soldered onto the board.

This not only extends the life of individual components but also simplifies repairs. If a single part fails, it can be replaced without discarding the entire board. This strategy directly supports PCB lifecycle management by reducing waste and encouraging reuse. Imagine a wearable device where the flex PCB’s sensor module can be swapped out for an upgraded version without needing a full replacement—such designs are the future of reusable component PCBs.

3. Designing for Disassembly

Many flex PCBs are integrated into devices in ways that make disassembly nearly impossible. Adhesives, tight layouts, and permanent soldering often mean that components can’t be salvaged at the end of a product’s life. To counter this, sustainable electronics redesign must prioritize ease of disassembly.

For example, using mechanical fasteners instead of adhesives or designing layouts with accessible connection points can make it easier to separate components. This approach not only aids in recycling but also supports the reuse of valuable parts, reinforcing the concept of circular economy PCBs.

4. Enhancing End-of-Life Recovery Processes

Even with the best design practices, some flex PCBs will reach the end of their usable life. To ensure a closed-loop PCB system, manufacturers must develop efficient recovery processes. This includes advanced recycling techniques that can separate and reclaim materials like copper, gold, and even certain plastics from flex PCBs.

Moreover, establishing take-back programs where manufacturers collect used devices for component recovery can significantly reduce e-waste. Such initiatives encourage a culture of responsibility and align with broader PCB lifecycle management goals. Data from industry reports suggest that effective e-waste management can recover up to 95% of valuable materials from PCBs if done correctly.

Challenges in Implementing a Circular Lifecycle for Flex PCBs

While the vision of a circular economy for PCBs is promising, several challenges remain. First, the cost of redesigning products and adopting new materials can be high, especially for smaller manufacturers. Developing modular designs or biodegradable substrates often requires significant upfront investment in research and tooling.

Second, there’s the issue of performance trade-offs. Eco-friendly materials may not yet match the durability or thermal resistance of traditional polyimide films, which are critical for high-performance applications. For instance, a flex PCB in a medical device must withstand repeated bending and high temperatures—something alternative materials might struggle with.

Finally, consumer behavior plays a role. Many users discard electronics without considering repair or recycling options. Educating end-users about the importance of returning devices for recovery is essential for a closed-loop PCB system to succeed.

Benefits of a Circular Lifecycle for Flex PCBs

Despite the challenges, the benefits of redesigning flex PCBs for a circular lifecycle are substantial. From an environmental perspective, reducing e-waste helps protect ecosystems from hazardous materials like heavy metals and toxic chemicals. Resource conservation is another major advantage—reusing components and materials decreases the demand for mining rare earth elements and other finite resources.

Economically, a closed-loop PCB system can lead to cost savings over time. Reusing components and materials reduces production costs, while take-back programs can foster customer loyalty. Additionally, as regulatory pressures for sustainability increase globally, companies that adopt circular economy PCBs will be better positioned to comply with new standards.

The Role of Technology in Sustainable Electronics Redesign

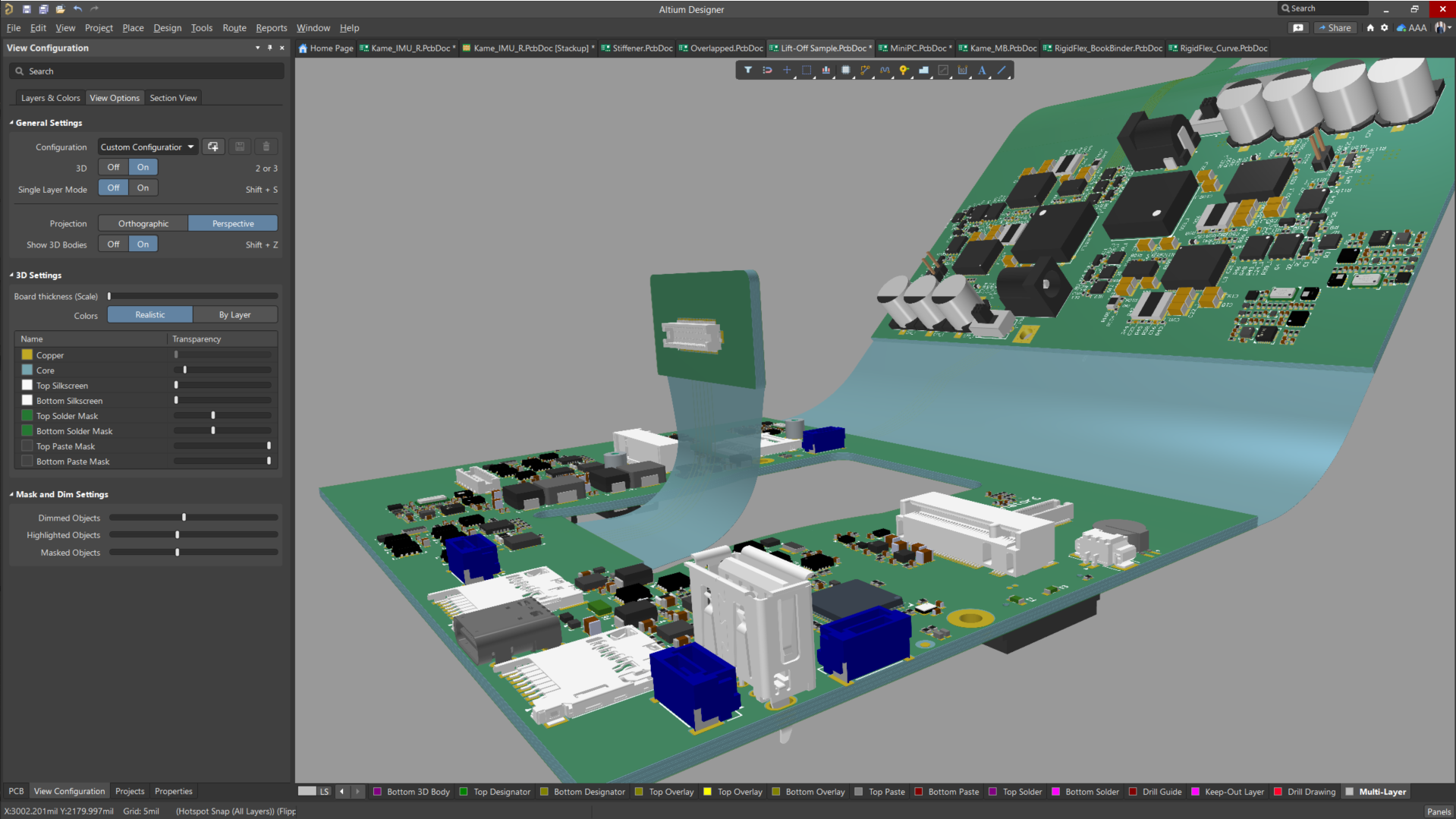

Technology is a powerful enabler in the journey toward sustainable electronics redesign. Advanced simulation tools can help engineers design flex PCBs with optimal layouts for disassembly and reuse. For example, software can predict stress points in a flex PCB under bending conditions, allowing designers to place components in ways that minimize wear and tear, extending the board’s lifespan.

Moreover, innovations in recycling technology, such as chemical separation processes, are making it easier to recover materials from complex PCB structures. These advancements are critical for scaling up PCB lifecycle management on a global level.

How Manufacturers Can Lead the Way

Manufacturers have a pivotal role in driving the transition to a circular lifecycle for flex PCBs. By investing in research for sustainable materials and modular designs, they can set new industry standards. Collaborating with suppliers to source eco-friendly raw materials is another critical step.

Additionally, manufacturers can implement pilot programs to test circular economy practices on a small scale before full adoption. For instance, producing a limited batch of flex PCBs with reusable component designs and tracking their lifecycle can provide valuable data on performance and recovery rates.

Looking Ahead: The Future of Circular Economy PCBs

The future of flex PCBs lies in embracing a truly circular lifecycle. As technology advances and consumer awareness grows, we can expect to see more devices designed with sustainability in mind. Innovations like fully biodegradable PCBs or universal component standards could revolutionize the industry, making a closed-loop PCB system the norm rather than the exception.

Industry projections indicate that the circular economy market will continue to expand, potentially reaching over USD 2 trillion by 2034. This growth signals a clear opportunity for the electronics sector to lead in sustainability, with flex PCBs at the forefront of this transformation.

Conclusion: Building a Sustainable Future with Flex PCBs

Moving beyond recycling to redesign flex PCBs for a circular lifecycle is not just an environmental imperative—it’s a strategic one. By focusing on circular economy PCBs, closed-loop PCB systems, and sustainable electronics redesign, the industry can address the growing problem of e-waste while unlocking new opportunities for innovation and efficiency.

Through thoughtful material choices, modular designs, and advanced recovery processes, flex PCBs can become a cornerstone of sustainable electronics. Effective PCB lifecycle management, paired with a commitment to reusable component PCBs, will ensure that resources are conserved, waste is minimized, and the electronics of tomorrow are built for a greener world.

At every stage of design and production, the goal remains clear: create products that don’t just end up in a landfill but instead contribute to a cycle of reuse and renewal. Together, we can redefine the future of flex PCBs and build an industry that prioritizes both performance and the planet.

ALLPCB

ALLPCB