If you're searching for the best materials to build high-performance drone PCBs, you've likely encountered the limitations of standard FR-4. While FR-4 is a reliable and cost-effective choice for many applications, it often falls short in the demanding world of drones, where high frequency, low signal loss, and thermal stability are critical. So, what are the alternatives? This blog dives deep into exotic materials like Rogers PCB, PTFE laminate, ceramic PCB, and other high-frequency, low-loss options that can elevate your drone's performance to new heights.

At ALLPCB, we understand the unique challenges of designing PCBs for drones. In this comprehensive guide, we'll explore why moving beyond FR-4 is essential for cutting-edge drone technology and break down the benefits, applications, and key considerations of these advanced materials. Whether you're an engineer or a hobbyist, you'll find actionable insights to help you make informed decisions for your next project.

Why Move Beyond FR-4 for Drone PCBs?

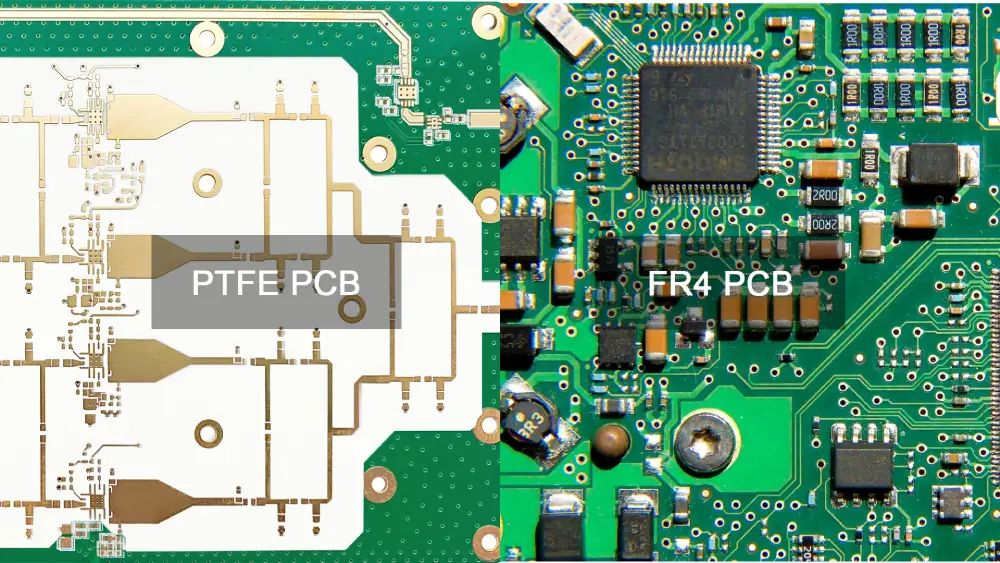

FR-4, a composite material made of woven fiberglass and epoxy resin, is the go-to substrate for most printed circuit boards due to its affordability and versatility. However, when it comes to high-performance drones, FR-4 has significant drawbacks. Drones often operate at high frequencies for communication and control systems, requiring materials that minimize signal loss and maintain stability under varying temperatures and environmental conditions.

FR-4 typically has a dielectric constant (Dk) of around 4.5, which can lead to signal delays and losses at frequencies above 1 GHz. Additionally, its loss tangent (Df) of about 0.02 indicates higher energy dissipation, which is problematic for radio frequency (RF) and microwave applications in drones. These limitations make FR-4 less suitable for advanced drone systems that rely on precise signal integrity for GPS, video transmission, and real-time control.

Exotic materials like Rogers PCB, PTFE laminate, and ceramic PCB substrates offer superior electrical properties, including lower dielectric constants (often between 2.2 and 3.5) and loss tangents as low as 0.0009. These characteristics ensure better signal integrity, faster data transmission, and improved overall performance—crucial factors for modern drones used in military, commercial, and recreational applications.

Understanding the Needs of High-Performance Drone PCBs

Drones are complex systems that integrate multiple high-speed components, including RF modules, antennas, sensors, and flight controllers. Each of these components demands specific electrical and thermal properties from the PCB substrate to function optimally. Here are some key requirements for drone PCBs:

- High-Frequency Performance: Drones often use frequencies in the 2.4 GHz to 5.8 GHz range for communication and video streaming. Materials must support these frequencies without significant signal attenuation.

- Low Signal Loss: A low loss tangent is vital to prevent energy dissipation, ensuring clear and reliable data transmission.

- Thermal Stability: Drones operate in diverse environments, from scorching deserts to freezing altitudes. PCB materials must maintain performance across wide temperature ranges.

- Lightweight Design: Every gram counts in drone design. Materials should offer high performance without adding unnecessary weight.

Exotic materials are engineered to meet these stringent demands, making them ideal for applications where standard substrates fall short. Let’s explore some of the top alternatives to FR-4 and how they can transform drone PCB design.

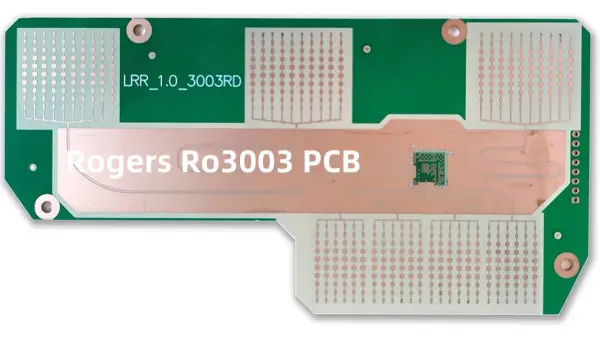

Rogers PCB: The Gold Standard for High-Frequency Applications

Rogers PCB materials are widely recognized as a leading choice for high-frequency applications, including drone PCBs. These laminates are made from advanced composites that combine woven glass or ceramic fillers with hydrocarbon or PTFE-based resins, offering exceptional electrical properties.

One of the standout features of Rogers PCB materials is their low dielectric constant, often ranging from 2.2 to 3.5, depending on the specific formulation. For instance, a popular variant has a Dk of 3.0 and a loss tangent of just 0.0013 at 10 GHz, making it ideal for RF and microwave circuits in drones. This ensures minimal signal delay and loss, which is critical for maintaining stable communication links over long distances.

Additionally, Rogers PCB materials provide excellent thermal stability, with some variants capable of operating in temperatures from -55°C to +150°C without significant changes in electrical performance. This makes them suitable for drones operating in extreme conditions. While these materials are more expensive than FR-4, their performance benefits in high-speed and high-frequency applications often justify the cost.

Applications in Drones: Rogers PCB materials are commonly used in drone antenna systems, RF transceivers, and high-speed digital circuits where signal integrity is paramount.

PTFE Laminate: Unmatched Low Loss for RF Performance

PTFE (Polytetrafluoroethylene) laminate, often referred to as Teflon in some contexts, is another top-tier material for high-performance drone PCBs. Known for its extremely low dielectric constant (typically around 2.1) and loss tangent (as low as 0.0002 at 10 GHz), PTFE laminate is one of the best options for minimizing signal loss in RF and microwave applications.

PTFE laminates are often reinforced with woven glass or ceramic fillers to enhance mechanical strength while maintaining their superior electrical properties. This combination makes them ideal for lightweight drone designs that require high-frequency performance. For example, a PTFE-based PCB can support stable signal transmission at 5.8 GHz, a common frequency for drone video feeds, with negligible attenuation.

One challenge with PTFE laminates is their higher cost and more complex manufacturing process compared to FR-4. However, for applications where low loss and high-frequency performance are non-negotiable, such as drone communication systems, the investment pays off in reliability and efficiency.

Applications in Drones: PTFE laminates are frequently used in drone RF modules, high-frequency antennas, and circuits requiring minimal signal distortion.

Ceramic PCB: Durability and Thermal Management

Ceramic PCBs are a unique category of substrates made from materials like alumina (Al2O3) or aluminum nitride (AlN). Unlike traditional laminates, ceramic PCBs offer exceptional thermal conductivity and mechanical strength, making them ideal for drone applications where heat dissipation and durability are critical.

Ceramic materials typically have a dielectric constant ranging from 6 to 10, which is higher than PTFE or Rogers laminates, but they excel in thermal management. For instance, aluminum nitride has a thermal conductivity of up to 170 W/mK, compared to FR-4’s mere 0.3 W/mK. This allows ceramic PCBs to handle high-power components in drones, such as motor controllers and power amplifiers, without overheating.

While ceramic PCBs may not be the first choice for high-frequency RF circuits due to their higher dielectric constant, they are invaluable in hybrid designs where thermal stability and ruggedness are priorities. Their ability to withstand harsh environmental conditions also makes them suitable for industrial and military drones.

Applications in Drones: Ceramic PCBs are often used in power management circuits, motor control systems, and other high-heat components of drones.

High-Frequency Material: Balancing Performance and Cost

Beyond specific branded materials, a wide range of high-frequency substrates are available that cater to the unique needs of drone PCBs. These materials are engineered to provide a low dielectric constant and minimal loss tangent, ensuring optimal performance at frequencies above 1 GHz.

For example, some high-frequency materials combine hydrocarbon resins with ceramic fillers to achieve a dielectric constant of around 3.2 and a loss tangent of 0.002 at 10 GHz. These properties make them suitable for drone applications like GPS receivers and wireless communication systems. Additionally, many high-frequency materials offer good thermal stability, with coefficients of thermal expansion (CTE) closely matched to copper, reducing the risk of delamination during temperature fluctuations.

While high-frequency materials can be more expensive than standard options, they often provide a middle ground between cost and performance, making them accessible for a wider range of drone projects.

Applications in Drones: High-frequency materials are versatile and can be used in communication circuits, sensor interfaces, and control systems.

Low Loss PCB: The Key to Signal Integrity

Signal integrity is a top priority for drone PCBs, especially in applications involving real-time data transmission and control. Low loss PCB materials, characterized by their low dielectric loss tangent, are designed to minimize energy dissipation and maintain clear signals even at high frequencies.

For instance, a low loss PCB with a loss tangent of 0.001 at 5 GHz can significantly reduce signal attenuation compared to FR-4, which might have a loss tangent of 0.02 under the same conditions. This difference translates to longer communication ranges and more reliable video feeds for drones.

Many low loss materials also offer excellent impedance control, which is crucial for matching the PCB traces to the connected components. This ensures minimal reflections and distortions, further enhancing performance.

Applications in Drones: Low loss PCBs are ideal for video transmission systems, RF communication links, and high-speed digital interfaces in drones.

Choosing the Right Material for Your Drone PCB

Selecting the best material for your drone PCB depends on several factors, including the specific application, frequency requirements, thermal constraints, and budget. Here are some tips to guide your decision:

- For RF and High-Frequency Needs: Opt for Rogers PCB or PTFE laminate materials with low dielectric constants and minimal loss tangents. These are best for communication and antenna systems.

- For Thermal Management: Choose ceramic PCB substrates if your drone design involves high-power components or operates in extreme temperatures.

- For Balanced Performance: High-frequency materials and low loss PCBs offer a cost-effective compromise for many drone applications, providing good electrical properties without breaking the bank.

At ALLPCB, we offer a wide range of advanced materials tailored to meet the needs of high-performance drone designs. Our team can help you navigate the options and select the ideal substrate for your project, ensuring optimal results.

Conclusion: Elevate Your Drone Design with Exotic Materials

Moving beyond FR-4 to explore exotic materials like Rogers PCB, PTFE laminate, ceramic PCB, and other high-frequency, low loss options can dramatically improve the performance of your drone PCBs. These advanced substrates address the unique challenges of high-speed communication, thermal management, and signal integrity, making them indispensable for modern drone technology.

Whether you're designing a drone for aerial photography, industrial inspection, or military use, the right PCB material can make all the difference. By understanding the properties and applications of these materials, you can create drones that are faster, more reliable, and capable of operating in the most demanding environments.

At ALLPCB, we're committed to supporting your innovation with cutting-edge PCB solutions. Explore our range of materials and manufacturing services to bring your high-performance drone designs to life. Let’s build the future of flight together.

ALLPCB

ALLPCB