Light at different wavelengths produces different effects when passed through the same lens, due to factors such as lens transmittance and chromatic aberration. Imaging across different spectral bands has distinct practical applications. For example, long-wave infrared (LWIR) imaging has been widely used for non-contact temperature measurement during the COVID-19 pandemic.

Lens

Lenses play a critical role in image quality produced by machine vision systems because they determine the sharpness of the image at the camera sensor.

Lenses can affect image quality in several ways:

- Reduced light transmission due to surface reflections at lens-air interfaces

- Spherical aberration, chromatic aberration and other defects that prevent all rays from a single object point from focusing to a single image point

- Reduced light intensity toward the image edges

- Spatial distortion of the image

The following sections summarize key considerations when selecting lenses for specific requirements, including wavelength, transmittance, and chromatic aberration.

Wavelength

The wavelength of the illumination is a primary consideration for lens selection because it strongly affects both chromatic behavior and optical transmission. This is important as infrared and ultraviolet illumination are increasingly used as alternatives to visible light to reveal information that is otherwise invisible. While broadband radiation is necessary for some applications such as color imaging, monochromatic illumination allows simpler lens designs and optimal performance at the selected wavelength.

Transmittance

Typically about 4% of incident light is reflected at each glass-air surface, resulting in roughly 8% loss for an uncoated lens element. Thin anti-reflection coatings on lens surfaces reduce these reflections and significantly increase transmission. Broadband coatings are used for color imaging, but the best transmission is obtained with coatings matched to a specific monochromatic source and lens design. Using wavelengths outside a coating's specified range will reduce transmittance.

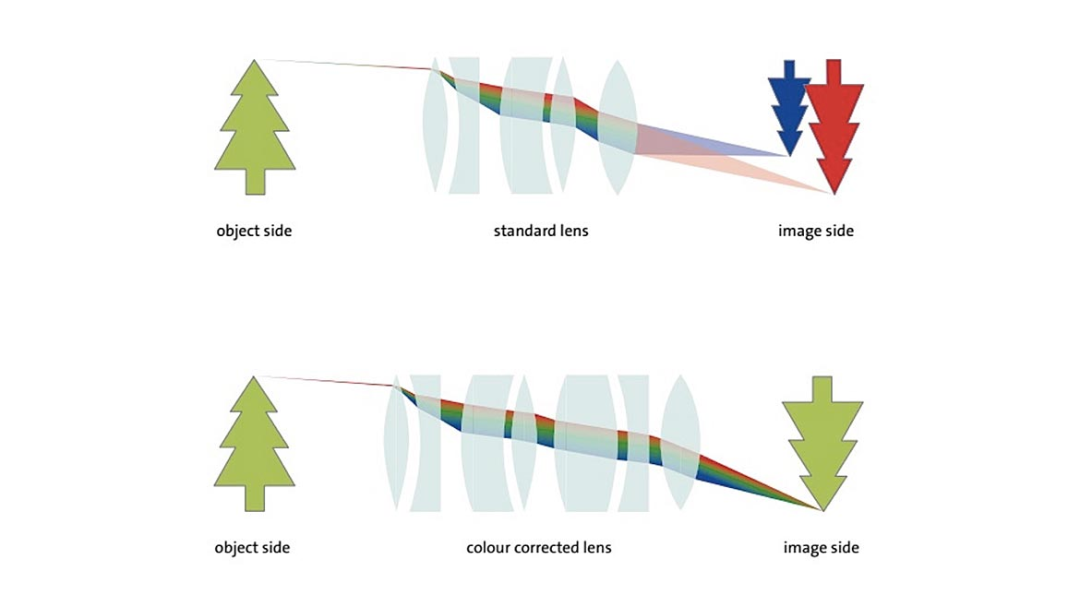

Chromatic aberration

Different wavelengths refract by different amounts at air-glass interfaces. This dispersion causes chromatic aberration, which blurs object edges and degrades measurement accuracy in machine vision. Hundreds of optical glass types with different dispersion properties are available, enabling achromatic lenses that use multiple glass elements to correct chromatic effects. When using monochromatic illumination, lens design can be much simpler because chromatic aberration is not a factor.

Line-Scan Imaging

Line-scan imaging inspects continuous materials and objects on conveyors, especially when object lengths vary. In line-scan systems, the camera's linear sensor scans at high speed to generate one image line at a time as the object passes beneath (see figure). Compared with area-scan imaging, the shorter pixel exposure time in line-scan systems makes lens transmittance critical for ensuring sufficient light reaches the sensor. Sensors can provide resolutions up to 16K pixels; for example, a 5 x 5 μm monochrome line sensor can exceed 80 mm in length. Large-format lenses are required to illuminate the full line array without mechanical vignetting (often caused by the lens mount) that would darken image edges. Anti-reflection coatings are essential to maximize light throughput.

Color line-scan imaging covers the full visible spectrum (400–700 nm) and therefore requires achromatic lenses with broadband anti-reflection coatings to control chromatic aberration and improve transmission.

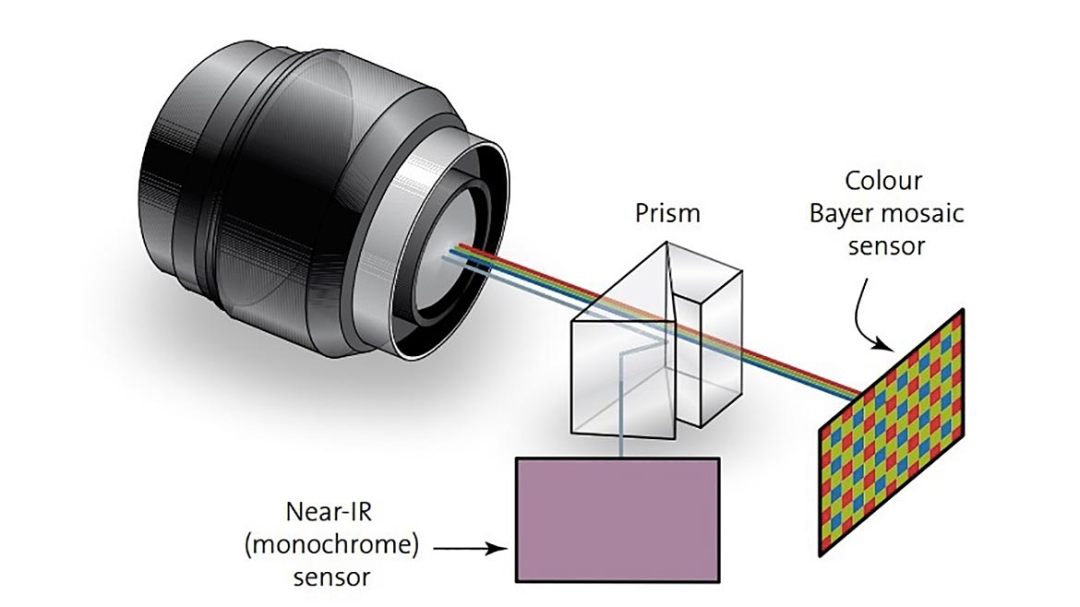

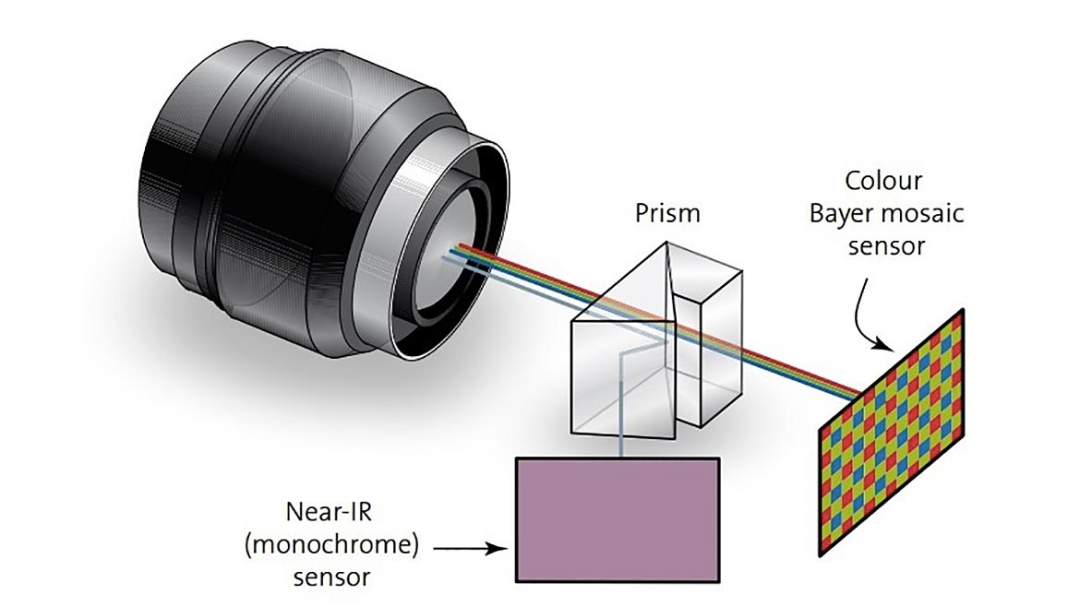

In single-chip cameras, outputs from two or three adjacent lines on the sensor are combined to generate RGB signals. In three- or four-sensor cameras, a prism collects light from the object and separates RGB components (and near-infrared in four-chip cameras) onto individual sensors for simultaneous detection. Prism-based designs use a common optical path, which is advantageous for imaging 3D objects or randomly moving products because R, G, B and NIR pixels coincide for any given object position. Lenses for prism-based cameras require special design to compensate for the prism's internal optical paths and focus characteristics. To avoid mechanical damage to the prism, the lens back element must also have low rear protrusion.

Near-Infrared (NIR) Imaging

The near-infrared band extends from about 700 nm to 1 μm. Standard CMOS sensors have some NIR sensitivity, and versions with enhanced sensitivity above 850 nm are increasingly common. NIR can reveal subsurface features such as decay, mechanical damage or pests in fruits, vegetables, nuts and meats. NIR illumination can also penetrate certain dyes and inks, enabling inspection through printed packaging. Applications include wood, textiles, paper, glass, tiles and electronics, and NIR is used to inspect labels on cylindrical or rotating objects such as cans, bottles and pens.

Combining pulsed NIR sources with NIR band-pass filters can eliminate adverse effects from fluctuating ambient light. If both NIR and color imaging are required, using two separate cameras can create alignment challenges. Multisensor prism cameras separate light into visible and NIR channels, each with its own sensor, providing perfectly registered images with identical fields of view. Lenses used with these cameras must be well matched to the prism's optical characteristics.

Short-Wave Infrared (SWIR) Imaging

SWIR covers roughly 1–5 μm, with many cameras optimized for 0.9–1.7 μm. These cameras require special detectors, such as indium gallium arsenide (InGaAs) or mercury cadmium telluride (MCT). SWIR cameras produce monochrome images with resolution and detail comparable to visible light, but fewer commercial optical glasses transmit well in this band. Some glasses exhibit lower dispersion at longer wavelengths, so achromatic designs may require more expensive, high-dispersion specialty glasses. Crystalline infrared materials such as zinc selenide and calcium fluoride have high dispersion properties but lower mechanical strength and higher cost than glass; therefore, most SWIR lenses still use glass with appropriate anti-reflection coatings. Water strongly absorbs in the SWIR region, enabling many moisture-distribution detection applications in agriculture and for checking fill levels of aqueous liquids in bottles.

Long-Wave Infrared (LWIR) Imaging

LWIR covers approximately 8–14 μm. LWIR cameras using microbolometer sensors detect naturally emitted thermal radiation, enabling surface temperature mapping with high accuracy up to about 250 °C. Thermal radiation can be detected at long range, in complete darkness, and through fog, dust, rain and smoke. Applications include surveillance, security, search and rescue, and industrial nondestructive testing and process monitoring. LWIR optics are typically made from germanium or chalcogenide materials such as Ge33As12Se55. Chalcogenide glasses have optical and mechanical properties similar to germanium but different refractive indices.

Ultraviolet Imaging

Ultraviolet imaging systems can resolve features finer than visible light, enabling submicron detail detection. This is useful for detecting scratches and defects on polished or highly reflective surfaces and for revealing very small surface details on printed circuit boards, documents and cards. Because ordinary glass attenuates ultraviolet, quartz lenses are used for UV-A (320–400 nm) and UV-B (290–320 nm) illumination, and achromatic doublets can be constructed for these bands.

Choosing a Lens

The illumination wavelength used in any machine vision application is a major factor in selecting the most suitable lens; broader spectral requirements demand more complex lens designs. Other factors include correction of additional aberrations and defects, and the physical environment in which the lens will operate. Given the large number of lenses available, working with a specialist in machine vision optics who can take a holistic approach to imaging requirements is often helpful. Few manufacturers cover every application, so targeted, application-specific optical advice is an important step toward a well-performing machine vision system.

ALLPCB

ALLPCB