If you're a hobbyist diving into the world of printed circuit boards (PCBs), you might have come across the term IPC-TM-650. But what exactly is it, and how can it help you with your DIY projects? In simple terms, IPC-TM-650 is a set of test methods created by the Institute of Printed Circuits (IPC) to ensure the quality and reliability of PCBs. For beginners, it offers a roadmap to test your boards effectively, even with limited resources. In this guide, we’ll break down IPC-TM-650 simplified, explore basic PCB tests for hobbyists, and share DIY PCB testing methods using low-cost PCB testing equipment. Let’s also dive into understanding IPC standards for home projects so you can build better, more reliable circuits.

What is IPC-TM-650 and Why Should Hobbyists Care?

IPC-TM-650 is a comprehensive manual of test methods developed by the IPC, an organization dedicated to setting standards for the electronics industry. This manual covers a wide range of tests to evaluate the performance, durability, and quality of PCBs. These tests are grouped into categories like visual inspection, mechanical testing, electrical testing, and environmental testing. While it’s primarily used by professionals in large-scale manufacturing, hobbyists can benefit from understanding and applying these methods on a smaller scale.

As a hobbyist, you might wonder why you need to bother with such standards. The answer is simple: testing your PCB ensures it works as intended and lasts longer. Even a small flaw, like a weak solder joint or a misaligned trace, can cause your project to fail. By following simplified versions of IPC-TM-650 tests, you can catch these issues early, saving time and money. Plus, learning these standards gives you a glimpse into professional practices, helping you improve your skills.

Breaking Down IPC-TM-650: Key Categories for Hobbyists

The IPC-TM-650 manual is vast, with over 100 test methods, but not all are relevant for home projects. Here, we’ll focus on the most practical categories for hobbyists and how you can apply them with limited equipment.

1. Visual Inspection (Section 2.1)

Visual inspection is the first and simplest step in PCB testing. IPC-TM-650 provides guidelines on what to look for, such as cracks in the board, uneven solder joints, or misaligned components. For hobbyists, this means using your eyes or a magnifying glass to check for obvious defects.

How to Do It: Hold your PCB under good lighting and examine it closely. Look for scratches on the copper traces, which should appear smooth and consistent (typically 1-2 oz copper thickness, or about 35-70 micrometers). Check if solder joints are shiny and rounded, not dull or cracked. If you spot a problem, it could indicate a manufacturing error or poor soldering technique.

Tools Needed: A magnifying glass (costing around $5-10) or a low-cost USB microscope (around $20-30) can make this process easier.

2. Dimensional Measurements (Section 2.2)

This category involves checking the physical dimensions of your PCB, such as the width of traces or the diameter of vias. IPC-TM-650 specifies acceptable tolerances, often in the range of ±0.1 mm for hobbyist-level boards.

How to Do It: Use a digital caliper (available for $10-15 online) to measure trace widths or hole sizes. Compare your measurements to your PCB design file. For example, if your design calls for a trace width of 0.3 mm, ensure it’s within ±0.05 mm of that value. Deviations could affect current carrying capacity, typically calculated as 1 amp per 0.025 mm2 of copper cross-section at 35 micrometers thickness.

3. Electrical Testing (Section 2.5)

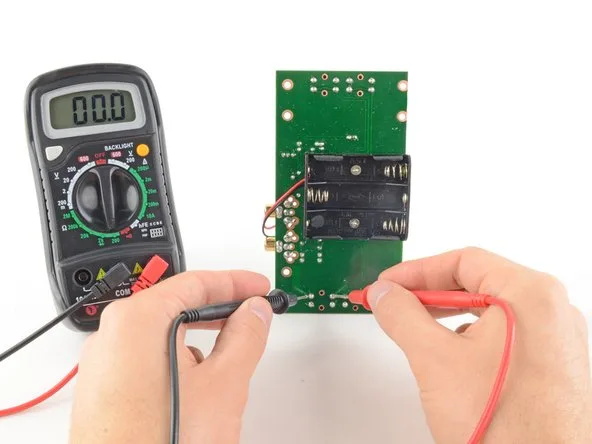

Electrical testing is crucial to ensure your PCB functions correctly. IPC-TM-650 includes methods like continuity testing and insulation resistance testing. For hobbyists, the focus is on basic checks using affordable tools.

Continuity Testing: This verifies that electrical paths (traces and vias) are connected as designed. Use a multimeter (priced at $10-20) set to continuity mode. Touch the probes to two points that should be connected; a beep indicates a good connection. If there’s no beep, you might have a broken trace.

Insulation Resistance: This checks for unwanted connections (shorts) between traces. Set your multimeter to resistance mode and test between adjacent traces. A reading above 10 megaohms is generally acceptable for most hobbyist projects, indicating no short circuit.

4. Environmental Testing (Section 2.6)

Environmental tests assess how your PCB holds up under stress like heat or humidity. While IPC-TM-650 uses advanced equipment for thermal cycling (e.g., -40°C to 125°C), hobbyists can simulate basic conditions at home.

How to Do It: Place your PCB in a warm area (like near a heater at 50-60°C) for a few hours, then check for warping or delamination. For humidity, leave it in a damp environment (like a bathroom after a hot shower) and inspect for corrosion on traces or components. These aren’t precise tests, but they give you an idea of durability.

DIY PCB Testing Methods for Hobbyists

While professional labs use expensive gear to follow IPC-TM-650, hobbyists can adapt these methods with DIY PCB testing methods and low-cost PCB testing equipment. Here are some practical approaches to get started.

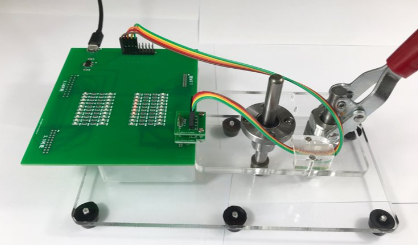

Building a Basic Test Setup

You don’t need a fancy lab to test your PCBs. A basic setup can include:

- Multimeter: For continuity, voltage, and resistance checks ($10-20).

- Magnifying Glass or USB Microscope: For visual inspections ($5-30).

- Digital Caliper: For measuring dimensions ($10-15).

- Power Supply: A variable DC power supply (5-12V, 1-2A) to test circuits under power ($20-40).

With a total investment of under $100, you can perform most basic tests outlined in IPC-TM-650.

Step-by-Step DIY Testing Process

Follow these steps to test your PCB at home, inspired by IPC-TM-650 guidelines:

- Visual Check: Inspect for physical defects using a magnifying tool. Look for uneven traces or poor soldering.

- Measure Dimensions: Use a caliper to confirm trace widths and hole sizes match your design specs.

- Test Continuity: Use a multimeter to ensure all intended connections are intact.

- Check for Shorts: Measure resistance between nearby traces to detect unintended connections.

- Power Test: Connect your PCB to a power supply at the rated voltage (e.g., 5V for most microcontrollers) and check if components operate without overheating. Monitor current draw—excessive current (above 500mA for small projects) could indicate a problem.

Understanding IPC Standards for Home Projects

Understanding IPC standards for home projects might seem intimidating, but it’s about applying the core principles of quality and reliability to your work. Here’s how you can adapt these standards without getting overwhelmed.

Focus on Relevant Standards

Besides IPC-TM-650, other IPC standards like IPC-A-600 (for bare board acceptability) and IPC-A-610 (for assembled board acceptability) provide visual and performance criteria. As a hobbyist, you don’t need to follow every detail, but skimming these documents (often available as free summaries online) can teach you what “good” looks like. For example, IPC-A-610 specifies that a solder joint should cover at least 75% of the pad for reliability.

Keep It Simple and Scalable

You’re not running a factory, so start with the basics: visual checks, simple electrical tests, and minimal environmental stress tests. As your skills grow, you can invest in better tools or try more complex IPC-TM-650 methods, like thermal stress testing with a controlled oven.

Low-Cost PCB Testing Equipment for Hobbyists

Testing doesn’t have to break the bank. Here’s a deeper look at low-cost PCB testing equipment that aligns with IPC-TM-650 simplified approaches:

- Multimeters: Look for models with continuity beeps and resistance ranges up to 20 megaohms. A basic model costs $10-15 and covers most electrical tests.

- USB Microscopes: These plug into your computer and offer 50-100x magnification for inspecting tiny solder joints or traces. Prices start at $20.

- Bench Power Supplies: A small adjustable power supply (0-30V, 0-3A) lets you test your PCB under different voltage conditions. Entry-level units cost $30-50.

- Thermal Cameras (Optional): If your budget allows, a basic thermal camera ($100-150) can spot overheating components, aligning with IPC-TM-650 thermal stress concepts.

Common PCB Issues Hobbyists Face and How IPC-TM-650 Helps

Even with careful design, PCBs can have problems. Here are common issues hobbyists encounter and how IPC-TM-650-inspired testing can help:

- Broken Traces: Detected through continuity testing. IPC-TM-650 suggests checking every critical path, ensuring no open circuits.

- Short Circuits: Use insulation resistance tests to find shorts, with IPC-TM-650 recommending readings above a specific threshold (e.g., 10 megaohms).

- Poor Soldering: Visual inspection per IPC-TM-650 guidelines can reveal cold joints or insufficient solder, which might cause intermittent failures.

- Component Failure: Power testing under controlled conditions (as suggested by IPC-TM-650 electrical tests) can identify weak components before they fail in use.

Tips for Success with IPC-TM-650 as a Hobbyist

To make the most of IPC-TM-650 in your home workshop, keep these tips in mind:

- Start Small: Focus on one or two test methods, like visual inspection and continuity, before moving to complex tests.

- Document Everything: Write down your test results (e.g., resistance values or trace measurements) to track issues over time, mimicking professional IPC-TM-650 reporting.

- Learn from Failures: If a test reveals a problem, analyze why it happened. Was it a design flaw or a soldering mistake? Use IPC guidelines as a reference to improve.

- Stay Safe: Always disconnect power before testing, and avoid high-voltage tests unless you have proper training and equipment.

Conclusion: Elevate Your Hobby with IPC-TM-650

As a hobbyist, diving into IPC-TM-650 simplified can transform the way you approach PCB projects. By mastering basic PCB tests for hobbyists and using DIY PCB testing methods with low-cost PCB testing equipment, you can build more reliable circuits without a big budget. Understanding IPC standards for home projects not only improves your skills but also connects you to the professional world of electronics. Start with the basics—visual checks, simple measurements, and electrical tests—and build from there. With practice, you’ll create PCBs that stand up to real-world use, all while following proven industry methods.

At ALLPCB, we’re passionate about supporting hobbyists and professionals alike in their electronics journey. Whether you’re testing a simple prototype or a complex design, applying these principles ensures quality every step of the way.

ALLPCB

ALLPCB