If you're new to the world of printed circuit boards (PCBs) and wondering how to ensure their quality, you've likely come across the term IPC-A-600. But what is IPC-A-600, and why is it important? Simply put, IPC-A-600 is a globally recognized standard that defines the acceptability criteria for PCBs, helping manufacturers and engineers ensure their boards meet quality requirements. Whether you're learning about PCB inspection for beginners or seeking an introduction to IPC-A-600, this guide will break down the basics and provide a clear path to understanding PCB quality standards.

In this blog, we'll dive deep into IPC-A-600 explained in simple terms, covering its purpose, key concepts, classes, and practical applications. By the end, you'll have a solid foundation in PCB quality standards for beginners and know how to apply these principles to your projects. Let's get started!

What Is IPC-A-600? An Introduction for Beginners

IPC-A-600, officially titled "Acceptability of Printed Boards," is a standard developed by the Institute of Printed Circuits (IPC), a global organization that sets guidelines for the electronics industry. This document serves as a visual and descriptive guide for determining whether a PCB meets the necessary quality standards for its intended use. It’s widely used by manufacturers, designers, and quality control professionals to ensure consistency and reliability in PCB production.

Think of IPC-A-600 as a rulebook. It provides detailed criteria for evaluating various aspects of a PCB, such as surface conditions, solderability, and structural integrity. By following these guidelines, you can avoid costly defects and ensure your boards perform as expected in applications ranging from consumer gadgets to critical aerospace systems.

Why IPC-A-600 Matters in PCB Manufacturing

Quality is everything in electronics. A single defect in a PCB can lead to system failures, safety hazards, or expensive recalls. IPC-A-600 helps prevent these issues by setting clear benchmarks for what’s acceptable and what’s not. For beginners, understanding this standard is crucial because it bridges the gap between design and manufacturing, ensuring that the final product matches the intended specifications.

For instance, imagine you're working on a PCB for a medical device. A small crack in the board or a poorly soldered connection could compromise the device's reliability, potentially endangering lives. IPC-A-600 provides the guidelines to spot such issues during inspection, allowing you to address them before they become problems.

Breaking Down the Basics of IPC-A-600

At its core, IPC-A-600 focuses on visual inspection criteria for PCBs. It categorizes defects and sets thresholds for acceptability based on the board's intended use. Here are some key concepts to grasp as part of IPC-A-600 basics:

- Acceptability Criteria: These are the specific conditions a PCB must meet to be considered usable. This includes aspects like the cleanliness of the board surface, the integrity of conductive traces, and the quality of holes or vias.

- Defect Classification: Defects are classified as "Acceptable," "Process Indicator," or "Defect." For example, a minor scratch on the surface might be acceptable, while a broken trace is a defect that requires rework.

- Visual Standards: The standard includes detailed illustrations and photographs to help inspectors identify issues. This visual aid is especially helpful for beginners learning PCB inspection.

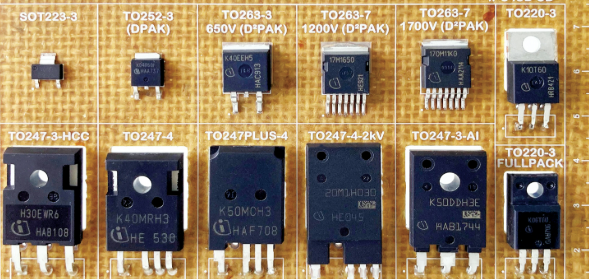

Understanding the Three Classes of IPC-A-600

One of the most important aspects of IPC-A-600 is its classification system. PCBs are divided into three classes based on their end-use application and the level of reliability required. These classes help determine the strictness of the acceptability criteria. Let's explore them:

Class 1: General Electronic Products

This class applies to consumer electronics where cost is a major factor, and the reliability requirements are less stringent. Examples include toys, basic household appliances, and non-critical devices. For Class 1 PCBs, minor cosmetic defects might be acceptable as long as they don't affect basic functionality.

Class 2: Dedicated Service Electronic Products

Class 2 is for products where reliability and extended life are important, but uninterrupted service isn't critical. Think of industrial controls, telecommunications equipment, or automotive electronics. The standards are stricter than Class 1, with less tolerance for defects that could impact performance over time.

Class 3: High-Reliability Electronic Products

Class 3 is the most demanding category, reserved for applications where failure is not an option. This includes medical devices, aerospace systems, and military equipment. Even small imperfections, like a slightly misaligned hole, can be considered a defect under Class 3 standards.

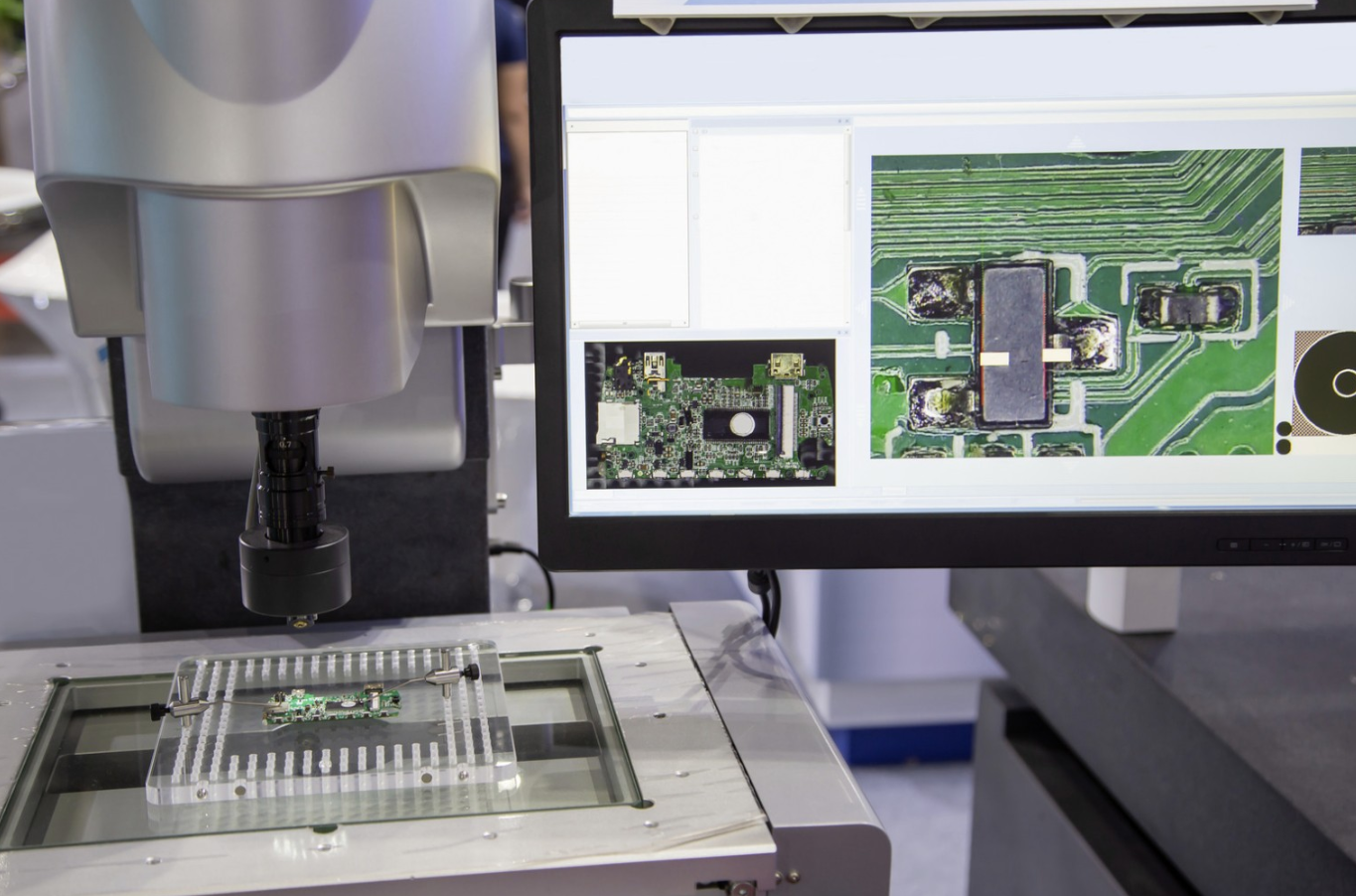

Understanding these classes is essential for PCB inspection for beginners because the class of your board dictates the level of scrutiny during quality checks. For example, a Class 3 board might require 100% inspection of all vias under a microscope, while a Class 1 board might only need a quick visual check.

Key Inspection Areas Covered by IPC-A-600

IPC-A-600 provides detailed guidelines for inspecting various parts of a PCB. For those new to PCB quality standards for beginners, here are some of the main areas covered by the standard:

1. Surface Conditions

The surface of a PCB must be free from contaminants, scratches, or oxidation that could affect solderability or performance. For instance, a tarnished copper surface might fail a solderability test, leading to poor connections.

2. Conductor and Trace Integrity

Conductive traces must be continuous and free from cracks, breaks, or narrowing that could disrupt electrical signals. IPC-A-600 specifies minimum trace widths and spacing to ensure signal integrity. For high-speed designs, maintaining trace impedance (often around 50 ohms for many applications) is critical.

3. Holes and Vias

Holes and vias (small conductive pathways connecting different layers of a PCB) are inspected for proper plating and alignment. Poorly plated vias can lead to weak connections, with resistance values spiking beyond acceptable limits (e.g., above 10 milliohms in some cases).

4. Solder Mask and Markings

The solder mask, which protects the PCB from environmental damage, must be intact and properly aligned. Markings, such as component labels, should be clear and legible for assembly purposes.

By focusing on these areas, you can ensure your PCB meets the necessary quality thresholds for its intended application.

How IPC-A-600 Works Alongside Other Standards

While IPC-A-600 focuses on the acceptability of bare PCBs, it’s often used in conjunction with other IPC standards to cover the entire manufacturing process. For example, IPC-6012 sets performance requirements for PCBs, while IPC-A-600 provides the visual criteria to assess whether those requirements are met. Together, they form a comprehensive framework for quality assurance.

For beginners, it’s helpful to think of IPC-A-600 as the "what to look for" guide, while other standards define "how to build" or "how to test." Understanding this relationship can streamline your workflow and improve overall product quality.

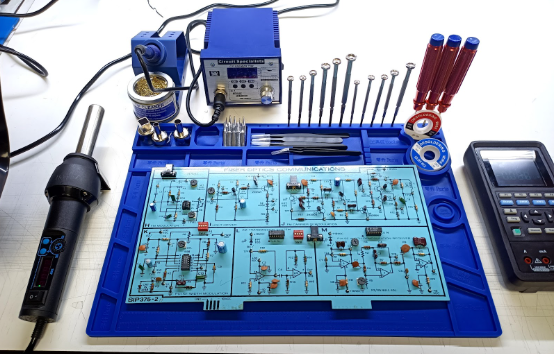

Practical Tips for Applying IPC-A-600 in PCB Inspection

Now that we've covered the basics, let's look at some actionable steps for using IPC-A-600 in your projects. These tips are tailored for those just starting with PCB quality standards for beginners:

- Start with the Right Class: Before inspection, identify the class of your PCB based on its application. This sets the tone for the level of scrutiny required.

- Use Visual Aids: Keep a copy of the IPC-A-600 document or its visual references handy. The images and descriptions are invaluable for spotting defects.

- Invest in Tools: Basic tools like magnifying glasses or microscopes can help you inspect fine details, especially for Class 2 and Class 3 boards.

- Document Findings: Record any defects or process indicators during inspection. This data can help improve future designs or manufacturing processes.

- Train Your Team: If you work in a team, ensure everyone understands IPC-A-600 basics. Consistent training reduces errors and improves inspection accuracy.

By following these steps, you can integrate IPC-A-600 into your quality control process and build more reliable PCBs.

Common Challenges and How to Overcome Them

Learning IPC-A-600 and applying it to PCB inspection can come with challenges, especially for beginners. Here are a few common hurdles and how to address them:

- Interpreting Visual Criteria: The standard’s images and descriptions can be overwhelming at first. Take time to study them and cross-reference with real PCBs to build familiarity.

- Balancing Cost and Quality: For Class 1 products, it might be tempting to overlook minor defects to save costs. However, ensure these don’t compromise basic functionality.

- Keeping Up with Updates: IPC-A-600 is periodically revised (e.g., versions like IPC-A-600J or K). Stay informed about the latest changes to avoid outdated practices.

With practice and patience, these challenges become manageable, and you'll gain confidence in applying the standard effectively.

Conclusion: Building Better PCBs with IPC-A-600

Understanding IPC-A-600 is a fundamental step for anyone involved in PCB design, manufacturing, or inspection. This standard not only ensures quality but also builds trust between manufacturers and clients by providing a common language for acceptability. Whether you're exploring PCB inspection for beginners or seeking a detailed introduction to IPC-A-600, the concepts and tips in this guide offer a strong starting point.

By mastering IPC-A-600 basics, you can contribute to creating reliable, high-performing PCBs for any application. From identifying defects to understanding the importance of different classes, this knowledge empowers you to maintain high standards in every project. Keep learning, keep inspecting, and let IPC-A-600 guide you toward excellence in PCB quality standards for beginners and beyond.

Ready to dive deeper into PCB manufacturing standards? Stay tuned for more insights and resources to elevate your skills in this ever-evolving field.

ALLPCB

ALLPCB