Stability is essential for efficient industrial production but is often challenged by equipment failures, parameter drift, and abnormal disturbances. Artificial intelligence, with its data mining, autonomous learning, and real-time decision capabilities, can help address these bottlenecks across equipment maintenance, process optimization, and other areas.

Intelligent maintenance and fault prevention

By installing sensors on equipment to collect vibration, temperature, and current data, and applying machine learning algorithms to build fault-prediction models, systems can predict the timing and type of upcoming failures based on historical and real-time data. This enables maintenance teams to schedule preventive maintenance in advance, avoiding unplanned downtime that would disrupt production stability. AI can also assess equipment health and estimate remaining useful life to support equipment replacement planning and ensure continuous, stable production.

Process parameter optimization

Machine learning algorithms can analyze large volumes of historical production data to predict optimal process parameter combinations and dynamically adjust settings based on real-time monitoring, improving process stability and efficiency. For example, a car manufacturer used AI algorithms to optimize welding processes, increasing production efficiency by 15% while maintaining process stability. AI can also support adaptive PID tuning to reduce the impact of environmental fluctuations, maintain stable control parameters, and indirectly save energy.

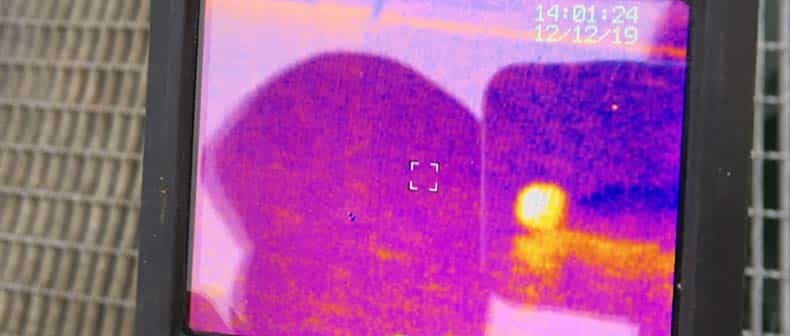

Anomaly detection and process diagnosis

Deep learning–based anomaly detection models trained on normal production data can quickly identify abnormal production behaviors and trigger early warnings to prevent issue escalation. Combined with knowledge bases and process data, these systems can localize process anomalies such as temperature-zone fluctuation or equipment stalling and suggest remediation steps, reducing downtime and limiting impacts on production stability.

Digital twin for virtual validation

Digital twin technology allows construction of virtual models for production lines or equipment so that AI-driven decisions can be validated in a virtual environment before execution, reducing the risk of causing real-world anomalies. For example, Siemens Industrial Copilot uses the Plant Simulation digital twin platform to validate AI-generated welding robot trajectories, raising the weld pass rate from 98.2% to 99.8%.

Enhancing adaptive control capabilities

Adaptive control approaches, such as fuzzy control and model predictive control, combined with deep learning, can increase system robustness against dynamic disturbances like material variability or external temperature changes. When operating conditions change, AI can drive real-time adjustments to control parameters or structures to maintain desired control performance, reduce manual interventions, and prevent production fluctuations during mode transitions.

Through these multidimensional applications, artificial intelligence provides systematic approaches to improve industrial automation stability by reducing the impact of unexpected failures and dynamically adapting to production changes. As these technologies mature, they will further support more reliable, efficient, and intelligent manufacturing processes.

ALLPCB

ALLPCB