If you're diving into the world of homemade PCBs and looking to elevate your projects with a professional touch, applying a matte solder mask during the DIY etching process is a game-changer. In this comprehensive guide, we'll walk you through every step of using a matte solder mask for DIY etching, from understanding its benefits to applying it at home. Whether you're a hobbyist exploring PCB fabrication or an enthusiast perfecting the PCB etching process, this article covers everything you need to know about matte solder mask DIY etching, homemade PCBs, and more.

What Is a Matte Solder Mask and Why Use It for Homemade PCBs?

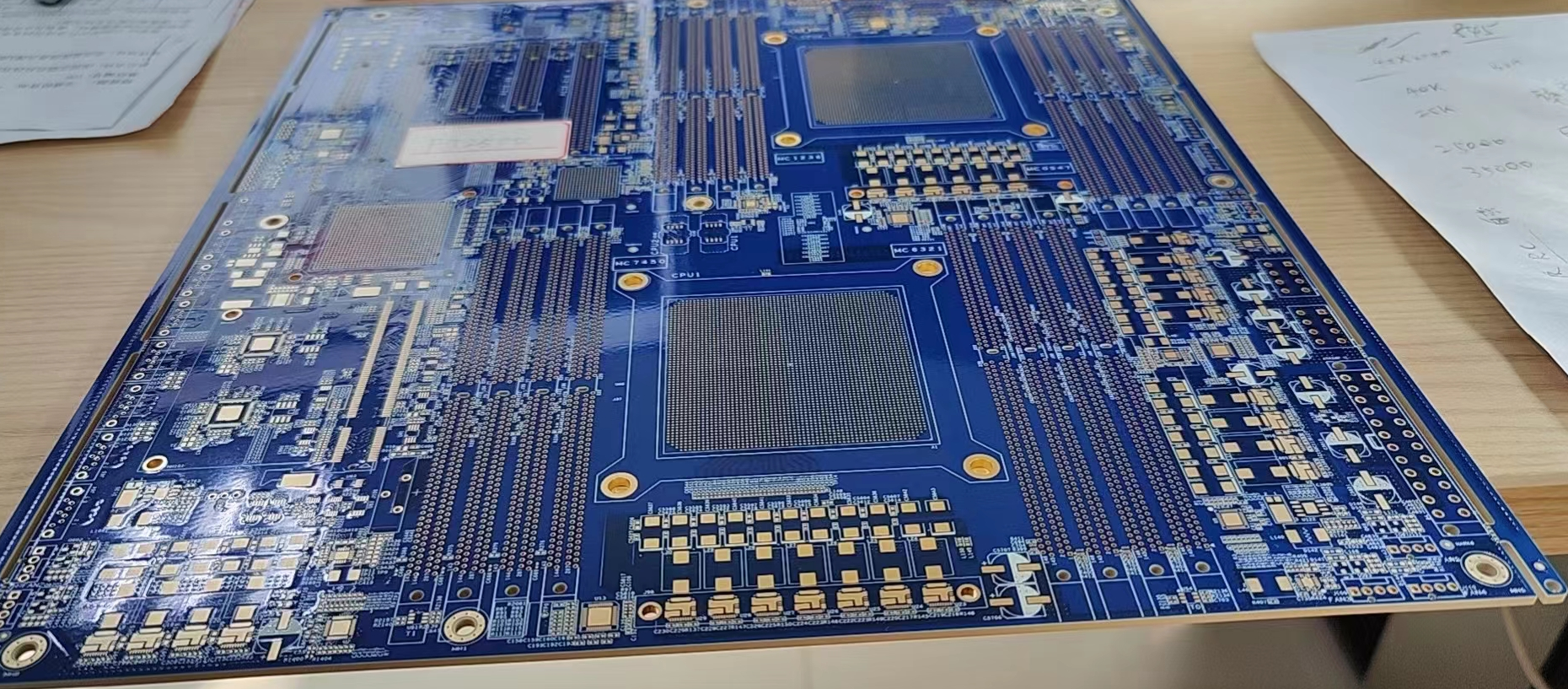

A solder mask is a protective layer applied to a printed circuit board (PCB) to shield the copper traces from oxidation, prevent solder bridges during assembly, and give the board a polished look. Unlike glossy finishes, a matte solder mask has a non-reflective surface that reduces glare, making it easier to inspect and photograph your work. For hobbyists engaged in PCB fabrication at home, using a matte solder mask during the DIY etching process offers several advantages:

- Enhanced Visibility: The non-shiny finish makes it easier to spot defects or misalignments under various lighting conditions.

- Professional Aesthetic: A matte finish gives your homemade PCBs a sleek, modern appearance.

- Better Durability: It protects copper traces from environmental damage, extending the life of your board.

Applying a solder mask at home might seem daunting, but with the right tools and steps, it's an achievable task that significantly improves the quality of your PCB projects. Let’s dive into the detailed process of matte solder mask DIY etching.

Understanding the PCB Etching Process for Hobbyists

Before we get into applying a solder mask, it’s important to grasp the basics of the PCB etching process. Etching is the method used to remove unwanted copper from a board to create the desired circuit pattern. For hobbyists working on homemade PCBs, this process typically involves a few key steps:

- Design Your Circuit: Use PCB design software to create your circuit layout. Print the design onto a transparency or special transfer paper.

- Prepare the Board: Clean a copper-clad board thoroughly to remove any dirt or grease that could interfere with the etching process.

- Transfer the Design: Transfer the printed design onto the copper board using heat (like an iron) or UV light exposure if using photoresist methods.

- Etch the Board: Submerge the board in an etchant solution, such as ferric chloride or a mix of hydrochloric acid and hydrogen peroxide, to remove unprotected copper. This usually takes 10-30 minutes, depending on the solution strength and board size.

- Clean and Inspect: Rinse the board with water to stop the etching process, then remove the protective layer to reveal the copper traces.

Once the etching is complete, the bare copper traces are exposed and vulnerable to oxidation. This is where applying a solder mask at home comes into play, adding both protection and a professional finish to your PCB.

Tools and Materials for Matte Solder Mask DIY Etching

To apply a matte solder mask at home as part of your PCB fabrication process, you'll need specific tools and materials. Here's a detailed list to ensure you're fully prepared:

- Matte Solder Mask Paint: Opt for a UV-curable solder mask in a matte finish. These are widely available online and designed for DIY use.

- UV Light Source: A UV lamp or exposure unit to cure the solder mask. A simple UV nail lamp can work for small projects.

- Transparency Film: To create a stencil or mask for exposing specific areas of the solder mask.

- Applicator Tools: A squeegee or small brush to evenly spread the solder mask over the PCB.

- Protective Gear: Gloves, safety goggles, and a well-ventilated workspace to handle chemicals safely.

- Cleaning Supplies: Isopropyl alcohol and lint-free cloths to clean the board before application.

- Developer Solution: A mild alkaline solution (often sodium carbonate) to remove uncured solder mask after UV exposure.

Having these materials ready will streamline the process of applying a solder mask at home and ensure a high-quality result for your homemade PCBs.

Step-by-Step Guide to Applying Matte Solder Mask at Home

Now that you have your tools and materials, let’s walk through the detailed steps of applying a matte solder mask during your DIY etching process. Follow these instructions carefully for the best outcome in your PCB fabrication journey.

Step 1: Prepare Your Etched PCB

Start with a clean, etched PCB. After completing the PCB etching process, remove any residue from the etchant solution by rinsing the board with water. Then, use isopropyl alcohol and a lint-free cloth to ensure the surface is free of grease, dust, or fingerprints. A clean surface is critical for proper adhesion of the solder mask.

Step 2: Create a Solder Mask Stencil

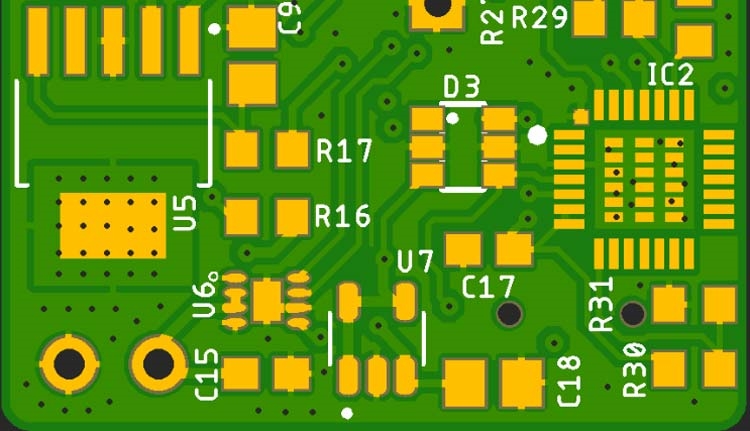

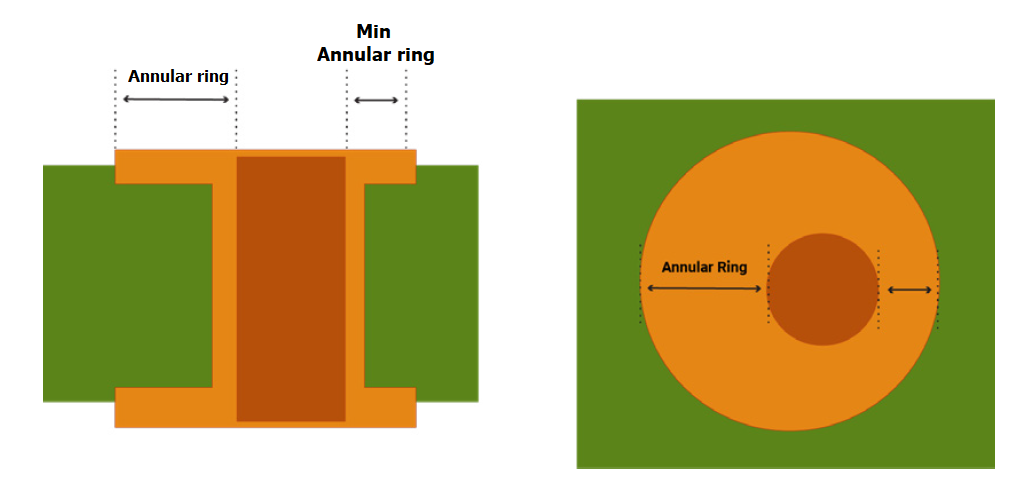

Print your solder mask design on a transparency film. This design should cover the areas where you want the solder mask to remain (typically everywhere except the pads and vias where components will be soldered). Ensure the printed areas are opaque to block UV light during exposure.

Step 3: Apply the Matte Solder Mask

Work in a dimly lit room to prevent premature curing of the UV-sensitive solder mask. Using a squeegee or brush, apply a thin, even layer of the matte solder mask paint over the entire surface of your PCB. Aim for a thickness of about 0.001 to 0.002 inches (25-50 micrometers) to avoid excessive buildup that could interfere with component placement.

Step 4: Align and Expose the Solder Mask

Carefully place the transparency film over the coated PCB, ensuring the design aligns perfectly with the copper traces and pads. Secure it in place with tape if needed. Then, expose the board to UV light using your UV source. Exposure time varies by product but typically ranges from 2 to 10 minutes. Check the solder mask manufacturer’s instructions for precise timing to avoid under- or over-exposure.

Step 5: Develop the Solder Mask

After exposure, remove the transparency film and place the PCB in a developer solution. Gently agitate the solution for 1-2 minutes to wash away the unexposed (uncured) solder mask, revealing the copper pads and vias. Rinse the board with water to stop the development process.

Step 6: Final Curing

Once developed, expose the PCB to UV light again for a longer duration (often 10-20 minutes) to fully cure the remaining solder mask. Some hobbyists also bake the board at a low temperature (around 120°C or 250°F) for 30 minutes to enhance durability, but check if this step is recommended for your specific solder mask product.

Step 7: Inspect and Clean

Inspect the board under good lighting to ensure the matte solder mask has been applied evenly and that all pads are clear of any residue. Use a small brush or compressed air to remove any debris. Your homemade PCB now has a professional matte finish ready for component assembly.

Tips for Successful PCB Fabrication for Hobbyists

Applying a solder mask at home can be tricky at first, but these tips will help you achieve better results during your matte solder mask DIY etching projects:

- Practice on Scrap Boards: Before working on your final design, test the solder mask application on a scrap piece of copper-clad board to get a feel for the process.

- Control UV Exposure: Overexposure can cause the solder mask to become brittle, while underexposure may leave it tacky. Stick to the recommended times for your specific product.

- Work in a Clean Environment: Dust or contaminants can ruin the solder mask finish. Keep your workspace clean and free of debris.

- Use Thin Layers: Applying multiple thin layers of solder mask (with curing in between) can prevent uneven coverage and ensure a smooth matte finish.

- Safety First: Always wear protective gear when handling chemicals like etchants and developers, and ensure proper ventilation in your workspace.

Common Challenges in Applying Solder Mask at Home and How to Overcome Them

Even with careful preparation, you might encounter some hurdles during the PCB etching process or solder mask application. Here are common issues and their solutions:

- Uneven Solder Mask Coverage: This often happens due to inconsistent application. Use a squeegee for even distribution and apply in thin layers.

- Solder Mask on Pads: If the mask covers areas meant for soldering, it’s likely due to misalignment of the transparency film. Double-check alignment before exposure, and use a fine tool to carefully scrape off any misplaced mask after curing.

- Poor Adhesion: If the solder mask peels off, the board might not have been clean enough. Ensure thorough cleaning with isopropyl alcohol before application.

- Bubbles or Imperfections: Bubbles can form if the mask is applied too thickly or if air gets trapped. Apply slowly and use a roller or squeegee to smooth out the layer.

Why Choose Matte Over Glossy Solder Mask for DIY Projects?

While both matte and glossy solder masks serve the same protective purpose, matte finishes have unique benefits for hobbyists engaged in PCB fabrication. Matte solder masks reduce glare, making it easier to inspect your board for tiny defects or soldering errors. They also tend to hide minor imperfections better than glossy finishes, which can highlight every scratch or uneven spot. For photography or documentation of your homemade PCBs, a matte finish provides a cleaner, professional look without reflections.

Conclusion: Elevate Your Homemade PCBs with Matte Solder Mask

Adding a matte solder mask to your DIY etching process is a fantastic way to protect your homemade PCBs while giving them a professional edge. By following this step-by-step guide, you can master the art of applying solder mask at home, from preparing your etched board to achieving a flawless matte finish. Whether you’re a beginner or an experienced hobbyist in PCB fabrication, incorporating a matte solder mask into your projects will enhance durability, functionality, and aesthetics.

With the right tools, patience, and attention to detail, the PCB etching process becomes not just a technical task but a rewarding creative endeavor. Start experimenting with matte solder mask DIY etching today, and take your homemade PCBs to the next level!

ALLPCB

ALLPCB