Introduction

With the rise of connected health, the market for medical smart wearables is expanding. Counterpoint Research reports that the pandemic has increased consumer health awareness, driving growth in medical wearable devices.

For this session, technical distributor Excelpoint invited engineer Feng from a company specializing in medical smart wearables to share practical cases. The company is engaged in research, development, manufacturing, sales, and service of medical diagnostic products. Engineer Feng has extensive academic and practical experience.

Project Requirements

- Small wearable form factor, requiring small-package components and high integration.

- Ultra-low power, rechargeable battery power supply.

- Continuous heart rate monitoring.

- Continuous blood oxygen saturation (SpO2) monitoring.

- Step counting, with at least one month of data storage and nonvolatile retention after power loss.

Heart Rate Monitoring

Heart rate can be measured from ECG signals, but ECG requires multiple body contact points, making the hardware complex and the solution costly. A resonant detection approach uses a sensor to detect arterial pressure changes and derive heart rate, but it requires placement over a pronounced pulse site, which complicates wearable form factors.

Photoplethysmography (PPG) is widely used in wearables. The method relies on blood absorption and reflection properties at specific wavelengths. Cardiac cycles change the blood volume in skin microvasculature; when using a green LED and a photodetector, the periodic change in received green light can be tracked. Each pulse produces a peak in the PPG waveform, and counting peaks yields heart rate. This approach is well suited to wrist-worn watch forms.

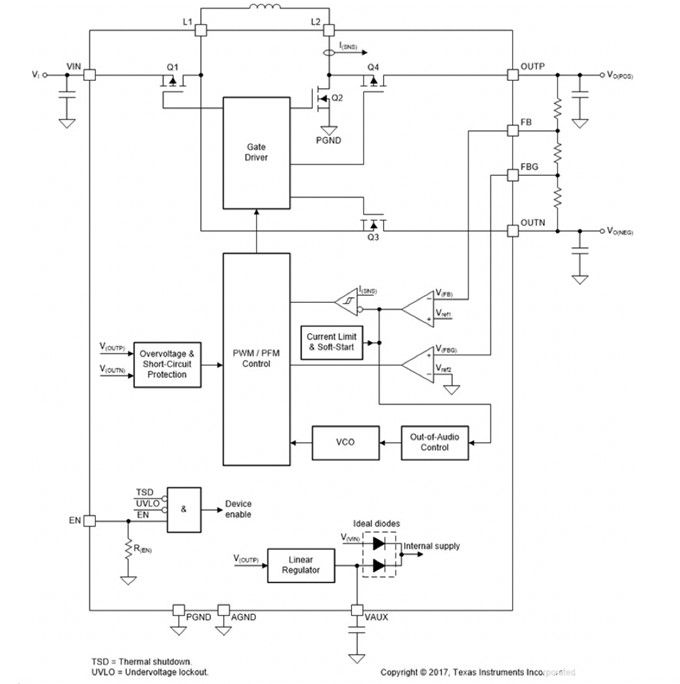

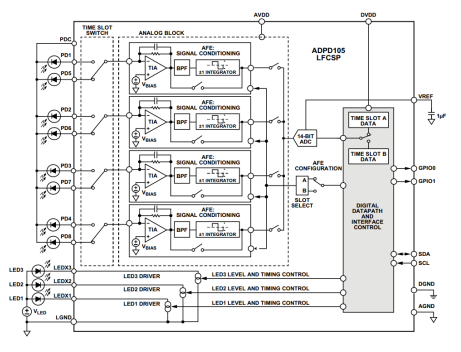

A PPG-based hardware chain requires an LED driver, photodetector with transimpedance and signal conditioning, an ADC for digitization, and an MCU for processing. Discrete implementations increase component count and board space, so highly integrated front-end devices are preferred. Analog Devices offers a multi-function optical measurement front-end (ADPD105) that integrates AFE, ADC, LED drivers, and timing core, provides strong ambient light suppression without photodiode filters, supports SPI or I2C digital interfaces, and runs from a 1.8 V analog/digital supply with standby currents as low as 0.3 μA. Sampling range is 0.122 Hz to 3820 Hz; it supports up to three LED current sources with per-channel peak currents up to 370 mA and is available in a WLCSP package suitable for space-constrained applications. The internal functional block diagram is shown below.

Figure 1

Blood Oxygen (SpO2) Monitoring

PPG can also be used for noninvasive SpO2 measurement after signal processing. Oxygenated hemoglobin (HbO2) and deoxygenated hemoglobin (Hb) have different absorption characteristics over 600–1000 nm. Hb absorbs relatively more light in the 600–800 nm range, while HbO2 absorbs relatively more in the 800–1000 nm range. By driving red LEDs (600–800 nm) and near-infrared LEDs (800–1000 nm) and acquiring the corresponding PPG signals, the ratio of the signals can be computed in software to estimate SpO2.

Using two LED current sources of the ADPD105 for red and near-IR and a third channel for green used in heart rate detection allows time-multiplexed reuse of a single photodetector to capture both heart rate and SpO2 signals. This minimizes component count and cost. A newer ADI product, the ADPD410x, provides higher integration with eight LED drivers and eight acquisition channels, higher sampling accuracy, and support for PPG, ECG, and EDA measurements, making it an option for expanded functionality.

Step Counting

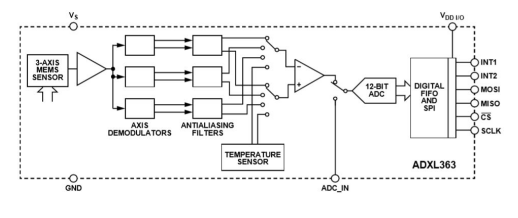

Step counting commonly uses a three-axis accelerometer and step detection algorithms that identify dynamic patterns in axis data during walking. For wearables, both power consumption and package size are critical. The ADXL363 is an ultra-low-power three-axis MEMS accelerometer that also integrates a temperature sensor and ADC input for synchronous conversion of external signals. At a 100 Hz output data rate, typical current consumption is under 2 μA; in motion-triggered wake mode it consumes 270 nA. Supply range is 1.6–3.5 V, easing compatibility with other system devices. The ADXL363 also exposes access to its ADC for synchronous sampling of external analog inputs. Its compact LGA package suits wearable applications. The internal functional block diagram is shown below.

Figure 2

MCU Selection

The MCU must balance performance and low power. Analog Devices' ADuCM3029 offers ultra-low-power operation: active mode typically <30 μA/MHz, sleep with SRAM retention typically <750 nA, and shutdown with optional RTC typically <60 nA. It integrates an ARM Cortex-M3 core with MPU for algorithm processing, 256 KB of ECC-protected flash for offline data storage, and operates from 1.74 V to 3.6 V, enabling coin cell use where applicable. Peripherals include SPI, UART, I2C, timers, DAC, DMA, and watchdog; internal oscillators include 32 kHz and 26 MHz, and external clocks are supported. Compact WLCSP/LFCSP packages are available for space-constrained designs.

For a higher-end option, the ADuCM4050 offers greater performance: active mode typically <41 μA/MHz, sleep with SRAM retention typically <650 nA, and shutdown typically <50 nA. It uses an ARM Cortex-M4F at 52 MHz with FPU, MPU, and debugging interfaces, and provides 512 KB of ECC-protected flash for larger offline data storage.

Power Management

Wearables require a rechargeable power source, typically a lithium battery, so battery management is necessary. The LTC4065L is a complete linear constant-current/constant-voltage charger for single-cell Li batteries in a small DFN 2 mm x 2 mm package. It supports accurate low charge currents suitable for low-capacity batteries, USB-standard power input, and protections such as automatic recharge, low-battery trickle charging, and soft-start for inrush current limiting.

MCU, accelerometer, and analog front-end devices may operate at 1.8 V, so an LDO is required to regulate the nominal 3.7 V lithium battery to the lower system voltage. Because analog circuits are used, a low-noise LDO is recommended. The LT3042 provides ultra-low noise of 0.8 μVRMS (10 Hz to 100 kHz), high power-supply rejection ratio (minimum 79 dB at 1 MHz), low dropout (350 mV), adjustable output, and comes in a compact DFN 3 mm x 3 mm package.

ALLPCB

ALLPCB