Introduction

Advanced Driver Assistance Systems (ADAS) use multiple vehicle-mounted sensors to collect environmental data, identify, detect, and track static and dynamic objects, and enable drivers to perceive potential hazards quickly. Automotive sensors fall into two broad categories based on purpose: traditional MEMS sensors that support vehicle control and information feedback, and intelligent sensors that provide environment perception for automated driving. MEMS devices act as a vehicle's "neurons" by providing feedback to control systems, while intelligent sensors act as the vehicle's "eyes".

1. Sensors as the Foundation of Vehicle Intelligence

Sensors are the primary information sources for automotive electronic control systems. A typical sensor consists of a sensitive element, a transducer element, and signal conditioning circuitry. The sensitive element directly responds to the measured quantity, the transducer converts that response into an electrical parameter, and the conditioning circuitry processes the electrical signal into a form suitable for processing, display, recording, or control. Based on application, automotive sensors can be divided into traditional MEMS sensors and intelligent sensors for automated driving.

Traditional Sensors

Traditional sensors provide information and feedback to vehicle control systems and enable automatic control. Functionally they include pressure sensors, position sensors, temperature sensors, accelerometers, gyroscopes, flow sensors, gas concentration sensors, and level sensors. These sensors are applied across powertrain, body control, and chassis systems, collecting data that electronic control units process to generate actuator commands.

Intelligent Sensors

Intelligent sensors provide environmental perception needed for automated driving. The main sensors used for environment perception are LiDAR, millimeter-wave radar, ultrasonic sensors, and cameras.

2. MEMS Sensors

MEMS sensors are manufactured using semiconductor fabrication and micromechanical processing techniques. They are widely applied in systems such as electronic stability control (ESP), anti-lock braking (ABS), electronic suspension control (ECS), and tire pressure monitoring (TPMS). Pressure sensors, accelerometers, gyroscopes, and flow sensors account for the majority of automotive MEMS usage.

Key MEMS advantages include:

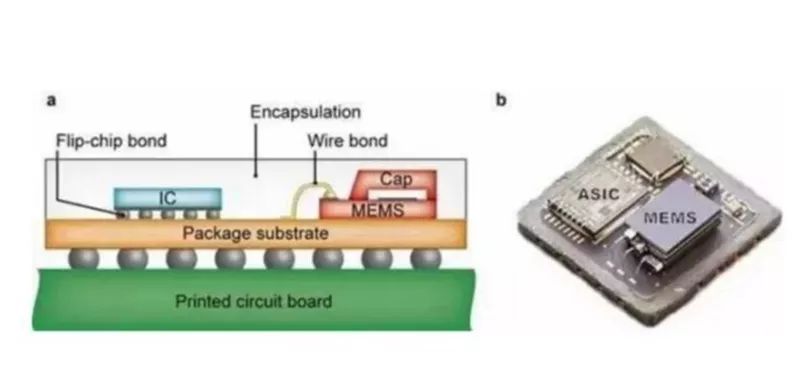

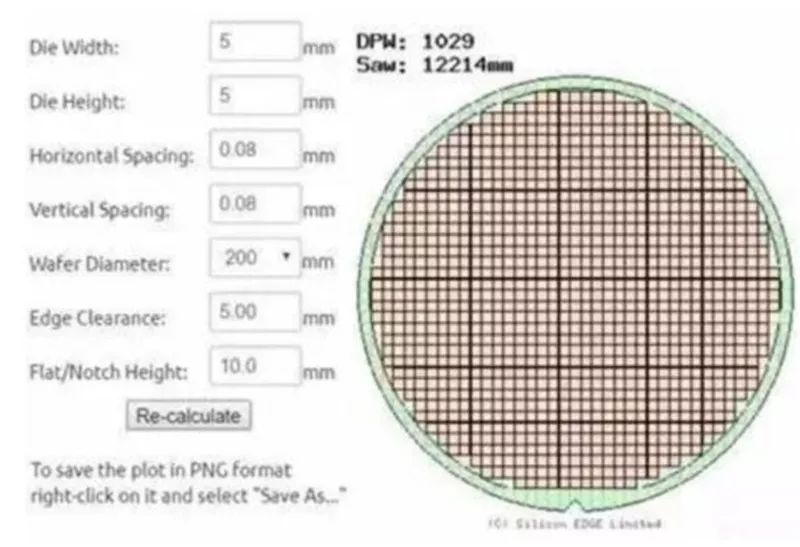

1) miniaturization; 2) silicon-based fabrication; 3) batch production; and 4) integration. MEMS devices are small, lightweight, and low-power, with high surface-to-volume ratios improving sensitivity. A 5 mm x 5 mm MEMS die can yield about 1,000 chips per 8-inch wafer, lowering unit cost through volume manufacturing. Individual MEMS devices often integrate ASICs for control and analog-to-digital conversion.

Global MEMS sensor supply is concentrated among large foreign manufacturers. In 2017 the top three MEMS suppliers accounted for about 57% of the market, led by Bosch. Large suppliers maintain product breadth and manufacturing capability that are difficult for smaller firms to replicate quickly. On average a vehicle contains about 24 MEMS sensors, with luxury models using 25-40 MEMS devices while entry-level models may use around five. Market estimates project continued growth in MEMS sensor market size through the early 2020s.

3. Intelligent Sensors: Core Technologies for Automated Driving

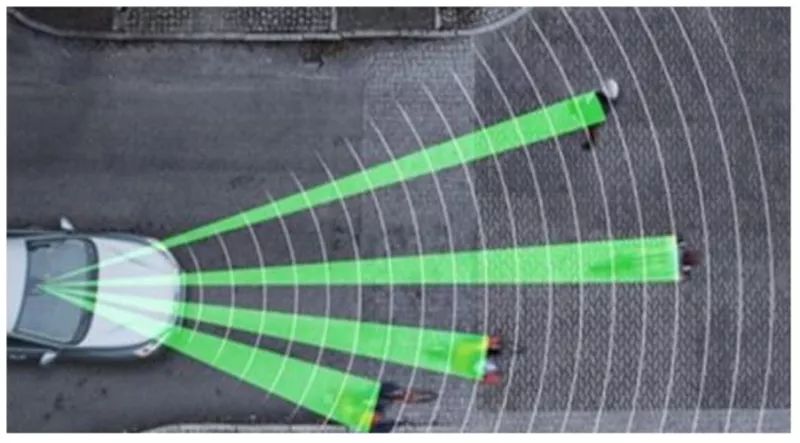

Millimeter-Wave Radar: A Core ADAS Sensor

Millimeter-wave radar measures distance by calculating echo time differences for millimeter-wave signals. Advantages include stable detection performance, long range, good environmental tolerance, small size, and high spatial resolution. Compared with optical sensors, millimeter-wave radar can penetrate fog, smoke, and dust, providing all-weather operation. Limitations include higher cost and more difficulty detecting pedestrians.

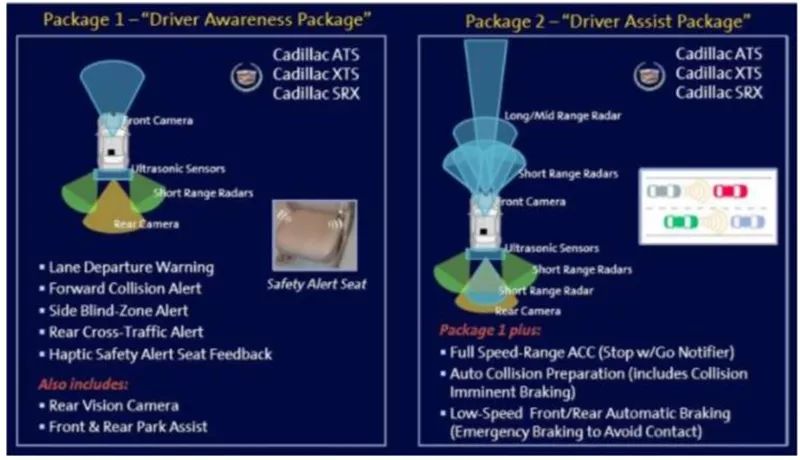

Two main automotive radar frequency bands are 24 GHz and 77 GHz. Compared with 24 GHz, 77 GHz offers higher range resolution and smaller size. Regulatory and evaluation changes in China have encouraged adoption of 77 GHz radar. Typical ADAS requires a combination of long-range and multiple mid/short-range radars; many vehicles use a 1 long + 4 mid/short configuration. Current system prices are roughly 1,000 RMB for 77 GHz units and 500 RMB for 24 GHz units.

Global millimeter-wave radar technology is dominated by companies from Germany, the United States, and Japan, with high market concentration among traditional automotive suppliers. In the Chinese market, high-end automotive radar is largely imported and supply is concentrated among foreign firms, although domestic suppliers are developing solutions. Market forecasts indicate rapid growth in millimeter-wave radar market size through the mid-2020s.

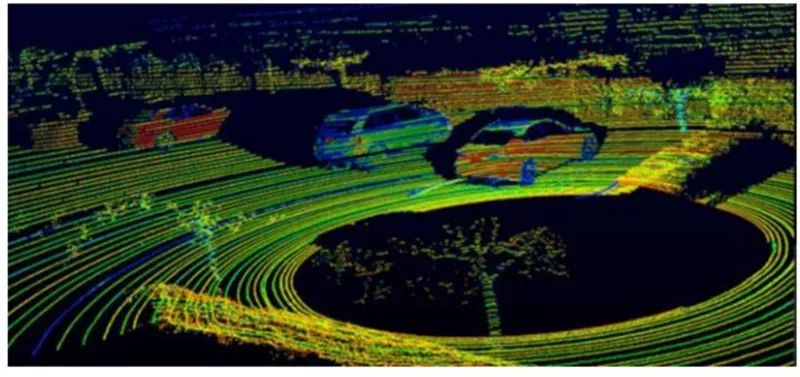

LiDAR: Key for SAE L3-L5 Automation

LiDAR measures distance by emitting and receiving laser pulses and timing the return. Common products use 8, 16, or 32 lines; more lines generally yield higher precision and safety margins. LiDAR provides high-precision, real-time 3D environment modeling and is expected to be crucial for L3-L5 automated driving.

Solid-state LiDAR is the industry trend because removing mechanical rotation reduces cost, size, and improves reliability. Cost reductions are also pursued by lowering line count and combining multiple low-line units. Core LiDAR technologies are concentrated among a few companies. High unit cost, challenging mass production, long lead times, and lack of standardized automotive regulations limit short-term large-scale adoption in passenger vehicles. Current LiDAR unit prices reported by manufacturers vary widely depending on line count and capability.

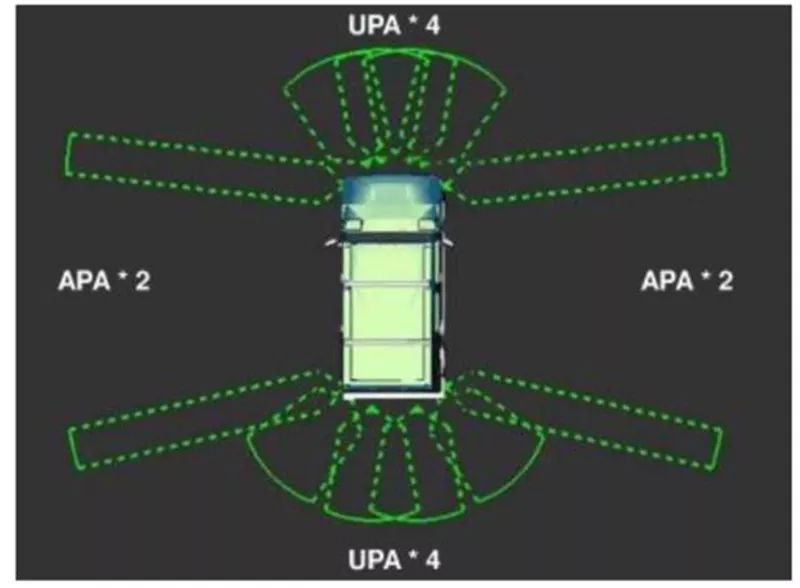

Ultrasonic Sensors: Mainstream for Parking Systems

Ultrasonic sensors measure distance by sending acoustic pulses and timing their echoes. They are low-cost, precise for short ranges (typically 0.1-3 m), and widely used in parking assistance and blind-spot warning. Their limited range and susceptibility to adverse weather are constraints.

Automatic parking systems drive demand for ultrasonic sensors. Typical backup parking systems use four ultrasonic sensors; full automatic parking systems may require 6-12 units. Ultrasonic sensor technologies include analog, four-wire digital, two-wire digital, and three-wire active digital schemes, with increasing interference resistance and complexity. Analog solutions dominate due to low cost, but digital architectures offer better noise immunity at higher cost and complexity.

Major global suppliers include Bosch, Murata, and Nissha. In the Chinese market, several domestic suppliers are competitive. Ultrasonic sensor market penetration is expected to grow in the near term due to parking and proximity sensing, though higher-level automated driving may replace some ultrasonic functions with radar or LiDAR in the long term.

Cameras: Primary Visual Sensors for ADAS

Vehicle cameras are the main visual sensors in ADAS. They capture images through lenses, convert them via image sensors and processing circuitry to digital signals, and support functions such as surround view, forward collision warning, lane departure warning, and pedestrian detection.

A full ADAS suite typically uses six or more cameras located at front, rear, sides, and inside the vehicle. Front-facing cameras require advanced algorithms and processors and are priced higher; rear, side, and interior cameras are lower cost. In the short term, monocular cameras remain the mainstream due to cost and reliability tradeoffs, while stereo camera systems are more common in higher-end vehicles.

Cameras typically complement radar and LiDAR, since optical sensors are sensitive to lighting and weather conditions. The camera industry supply chain includes upstream components (CMOS sensors, lens modules, DSPs), midstream module packaging and system integration, and downstream vehicle integration. Component markets for image sensors and DSPs are dominated by a few global suppliers, while local manufacturers are competitive in lens production. Automotive camera certification and qualification cycles are lengthy due to harsh operating conditions and high reliability requirements.

4. Multi-Sensor Fusion Is the Inevitable Trend

ADAS development is driving demand for multiple sensor types. Global ADAS penetration remains modest in many regions, and penetration in China is lower than in some markets. As ADAS moves from introduction to growth, environment perception sensors will be essential, and higher ADAS penetration will significantly increase demand for vehicle sensors.

Different sensors have complementary strengths and limitations. Millimeter-wave radar offers a strong overall combination of performance characteristics and is poised to become a primary ADAS sensor. No single sensor provides complete information coverage; multi-sensor fusion is required to achieve Level 3 to Level 5 automated driving. Two main technical routes exist: vision-dominant fusion exemplified by Tesla, and LiDAR-led approaches exemplified by Waymo. Major OEMs publish multi-sensor roadmaps that emphasize fusion for robust environment understanding and vehicle positioning.

In summary, ADAS systems rely on cameras, radar, LiDAR, and ultrasonic sensors to detect optical, thermal, pressure, and other variables related to vehicle state. These sensors are typically mounted on bumpers, mirrors, steering columns, or windshields. Sensor data, combined with processing units such as MCUs and image processors, form the core of ADAS functionality. The maturation of ADAS is a foundational step toward achieving full autonomous driving.

ALLPCB

ALLPCB