The body control module (BCM) is a critical electronic control unit (ECU) in modern vehicles, managing various body-related functions. This article explores its role, functionalities, hardware architecture, future trends, and challenges.

Overview of the Body Control Module

The BCM is an ECU typically located behind the dashboard or under a seat. It serves as the central hub for controlling body-related functions such as lighting, windows, door locks, and seat adjustments. The BCM communicates with other ECUs using protocols like CAN, LIN, or FlexRay, ensuring seamless operation of vehicle electrical systems.

Without a BCM, many electrical systems in a vehicle would not function efficiently or at all, making it a cornerstone of modern automotive design.

Key Functions of the BCM

The BCM manages a wide range of vehicle functions by communicating with other modules and systems via CAN, LIN, or Ethernet. Based on input signals, it controls the following:

- Window Control: Manages power window operations.

- Lighting Control: Oversees external and internal lighting, including automatic headlights, taillights, turn signals, and dimming functions.

- Door Lock Control: Processes signals to lock or unlock all doors.

- Climate Control: Coordinates heating, ventilation, and air conditioning, allowing adjustments to temperature, HVAC modes, and fan speed.

- Security Features: Supports keyless entry, anti-theft, and alarm systems.

- Wiper Control: Manages windshield wiper functions, including intermittent modes.

- Comfort Features: Controls actuators for seats, mirrors, and other adjustable components.

- Diagnostics and Reporting: Stores diagnostic data to identify and troubleshoot electrical issues.

- Gateway Integration: Facilitates communication between control units via vehicle bus systems.

- Energy Management: Optimizes electrical component operation to reduce power consumption, improving fuel efficiency in conventional vehicles and extending range in electric vehicles.

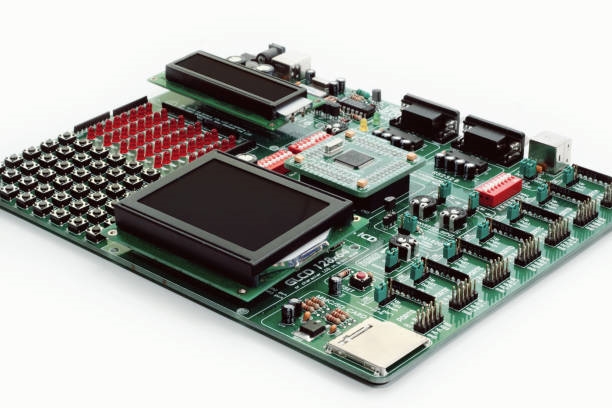

BCM Hardware Architecture

The BCM's architecture integrates various components to control vehicle electrical systems. At its core is a microcontroller unit (MCU) that processes inputs from sensors and switches to execute commands. The MCU connects to multiple input/output (I/O) modules interfacing with electrical components.

The BCM includes load drivers such as high-side/low-side switches, relay drivers, and motor drivers to manage systems like lighting, power windows, seats, wipers, door locks, and horns. It uses communication protocols (CAN, LIN, FlexRay) to exchange data and commands with other ECUs, enabling coordinated system control.

Future Trends in BCM Development

BCM architectures are evolving into two main types: distributed and centralized.

Distributed BCM

Distributed BCMs address the complexity of numerous, scattered loads (e.g., lighting, seats, HVAC) across the vehicle. Direct wiring for each load increases wiring harness complexity, cost, and weight. Distributed ECUs use bus systems, often LIN Slave structures, to connect loads as nodes, simplifying wiring and reducing weight.

Centralized BCM

Centralized BCMs focus on platformization and high integration. Platformization ensures compatibility with universal components, while integration consolidates functions into fewer chips, such as system basis chips (SBCs) combining power, CAN, and LIN transceivers. Some designs, like Tesla's, integrate thermal management and motor control into the BCM.

Benefits of centralized BCMs include:

- Fewer electronic modules and cables

- Reduced vehicle weight

- Improved fuel efficiency

- Lower manufacturing costs

Centralized BCMs are a clear trend for future development.

Emerging Technologies

Future BCMs will integrate advanced driver assistance systems (ADAS), such as adaptive cruise control, lane-keeping assist, and collision avoidance, enhancing automation and safety. Connectivity features will also enable communication with external devices (e.g., smartphones, cloud services), supporting remote control, real-time updates, and personalized services.

Challenges Facing BCM Development

As BCMs evolve, they face several challenges:

- Complexity: Advanced vehicle technologies increase the number of functions BCMs must manage, requiring higher MCU performance, more I/O channels, and complex diagnostics.

- Power Management: With growing electrical system demands, BCMs must minimize power consumption to prevent battery drain, using strategies like sleep modes and power gating.

- Compatibility: Ensuring seamless integration with diverse vehicle models and components is challenging in a rapidly evolving market.

- Security: As vehicles rely more on electronic systems, BCMs must be protected against cyber threats using secure communication protocols and encryption.

In summary, the BCM's role will continue to expand with technological advancements, enabling more sophisticated control and convenience features, and driving vehicles toward greater intelligence and electrification.

ALLPCB

ALLPCB