The rapid advancement of artificial intelligence (AI) systems, driven by large datasets, machine learning algorithms, and high-performance computing hardware, has created significant opportunities across various fields. However, it also introduces complex challenges, particularly in the design of AI accelerator chips. These chips, capable of processing vast amounts of data at high speeds, face critical issues related to thermal management and electromagnetic interference (EMI).

Thermal Management in High-Performance AI Chips

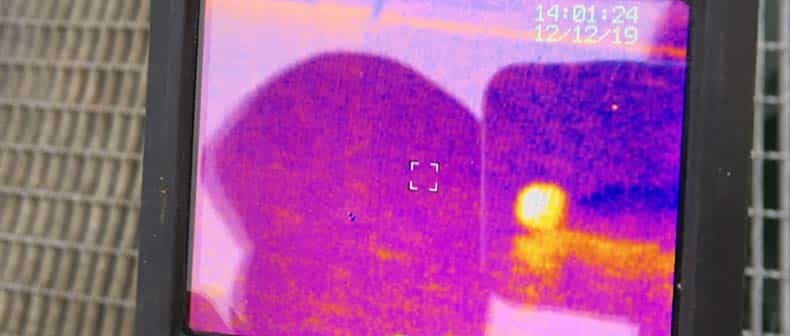

AI accelerators consume significantly more power than traditional processors, generating substantial heat. Effective heat dissipation is a critical concern, as many thermal interface materials struggle to provide the low thermal resistance needed to manage high heat loads. Inadequate cooling can lead to elevated temperatures, reduced performance, and even processor failures.

As power densities in AI chips increases, the challenge of maximizing heat transfer intensifies, compounded by the need to reduce energy costs associated with cooling. Advanced thermal interface materials, such as phase-change materials, greases, and gels, offer low thermal resistance to address these demands, ensuring long-term reliability for high-performance applications.

Electromagnetic Interference in AI Chip Design

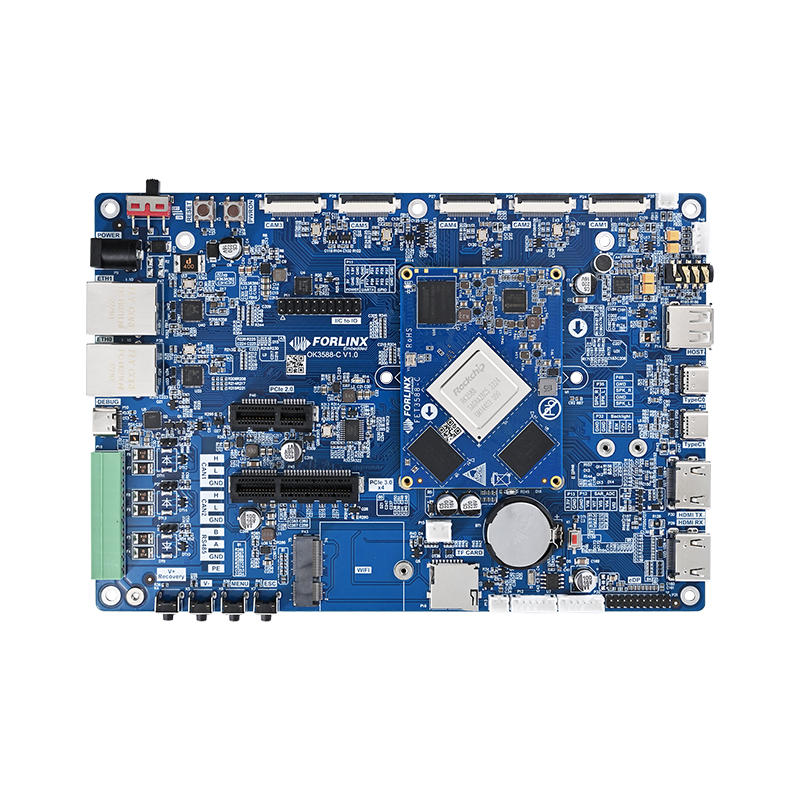

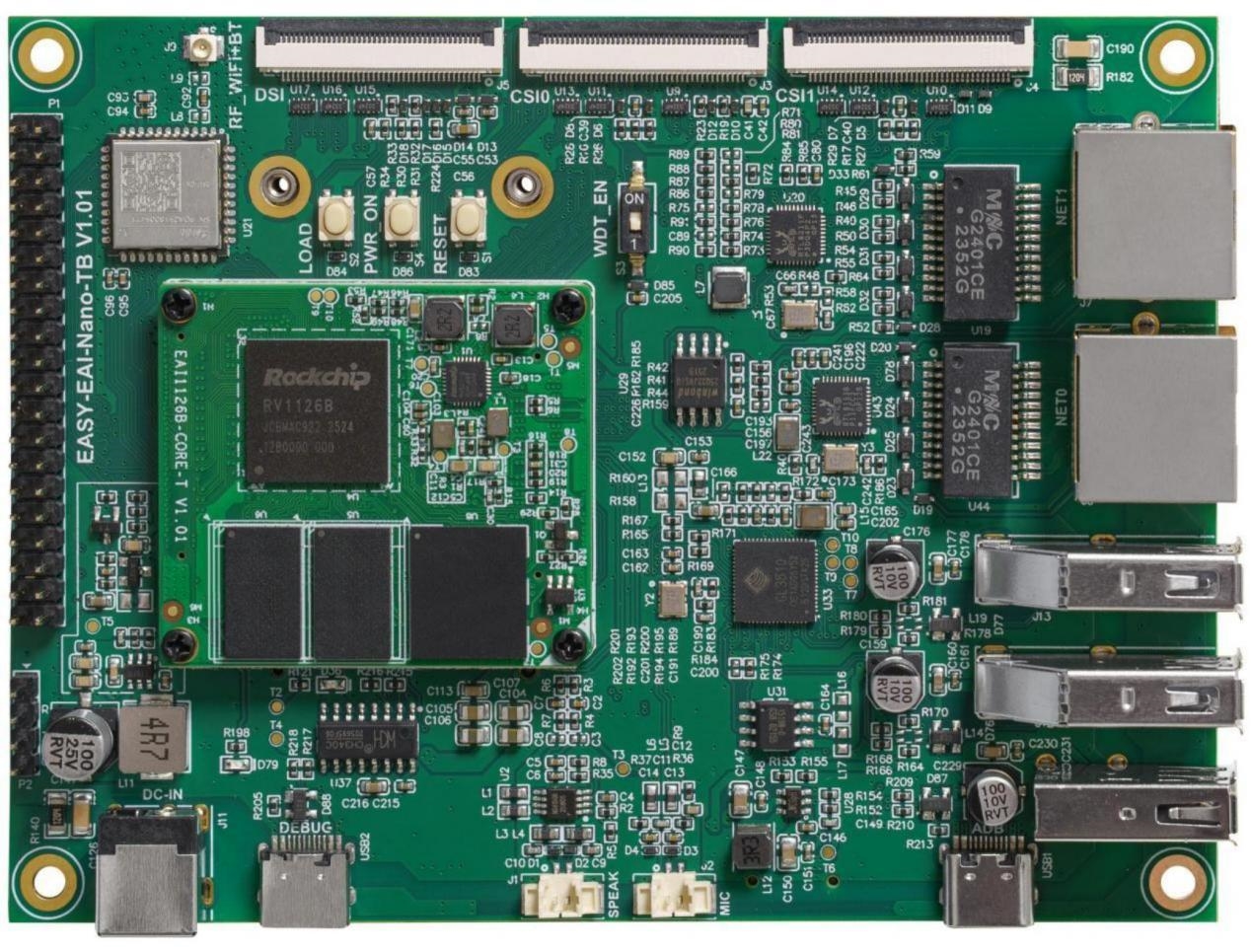

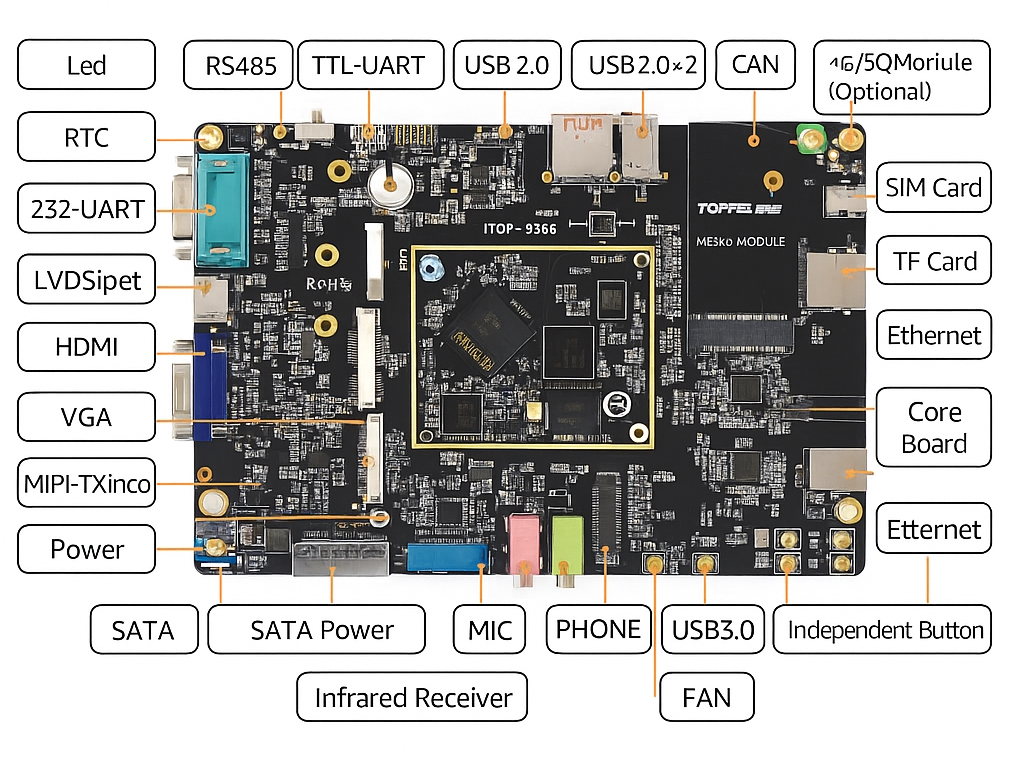

Beyond thermal issues, electromagnetic interference (EMI) poses a significant challenge for high-performance AI chips. The increasing power and circuit board density in modern AI designs exacerbate EMI, which can degrade chip performance and introduce unwanted noise. In data centers, where AI chips operate continuously, EMI affects not only the chip architecture but also the entire printed circuit board (PCB), impacting long-term reliability.

Addressing EMI Early in Design

To mitigate EMI, designers must address noise issues early in the architecture development cycle. Key considerations include device crosstalk, power management, low- and high-frequency applications, linearity, and circuit board density. Early-stage trade-offs are essential to optimize chip performance and minimize interference.

Solutions such as absorber sheets, dispensable materials, and 3D injection-molded absorbers are designed to handle the high-frequency demands of AI applications, supporting faster data rates and higher bandwidths. Advanced modeling, simulation, and predictive analytics further enable tailored solutions, helping designers achieve compliance and accelerate time-to-market.

Integrated Solutions for Thermal and EMI Challenges

A growing trend in circuit board design is the adoption of multifunctional, all-in-one solutions that address both thermal and EMI challenges. These integrated solutions combine effective heat dissipation and noise suppression in a compact, space-saving package, reducing the overall footprint on the PCB. Such approaches are increasingly critical as AI chip designs push the boundaries of performance and density.

ALLPCB

ALLPCB