In the fast-paced world of electronics, designing a printed circuit board (PCB) that performs flawlessly is more critical than ever. Whether you're an engineer working on high-speed digital circuits or a hobbyist creating a prototype, mastering PCB routing software and advanced routing techniques can make or break your project. This blog dives deep into the latest routing rules and strategies, covering essentials like differential pair routing rules, blind and buried vias routing, trace width calculation software, and impedance matching routing. Let’s explore how these advanced methods in PCB design software are revolutionizing the way we create reliable and efficient boards.

Why Advanced PCB Routing Matters

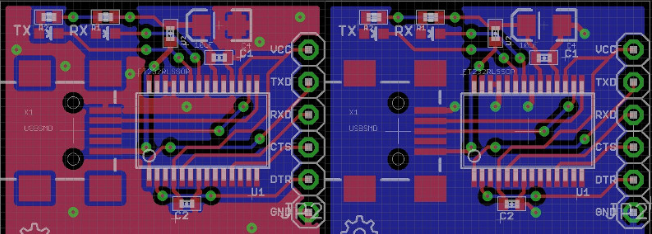

PCB routing is the process of connecting components on a board using conductive traces. While it might seem straightforward, routing directly impacts signal integrity, power distribution, and electromagnetic compatibility (EMC). Poor routing can lead to issues like signal delays, crosstalk, or even complete circuit failure. With modern devices pushing for faster speeds and smaller footprints, advanced routing techniques in PCB routing software have become indispensable.

Advanced routing isn't just about connecting points A to B. It’s about optimizing every trace, via, and layer to ensure the board performs under real-world conditions. From high-speed data transfer in USB or HDMI interfaces to maintaining signal integrity in complex multilayer boards, mastering these techniques can elevate your designs to the next level.

Understanding Key Routing Challenges in Modern PCB Design

Before diving into specific techniques, it’s important to recognize the challenges that modern PCB designs face. Devices are shrinking, yet they’re expected to handle higher frequencies—sometimes in the range of 5 GHz or more for applications like 5G or PCIe. These demands create unique hurdles, such as managing signal reflections, minimizing noise, and ensuring thermal stability. Advanced PCB routing software addresses these challenges by offering tools and rules that guide engineers through the design process.

Signal Integrity and High-Speed Design

At high frequencies, signals can behave unpredictably. A trace that’s too long or improperly routed might act like an antenna, picking up or radiating interference. Signal integrity issues can cause data errors or system crashes. Advanced routing techniques, such as impedance matching routing, help maintain consistent signal paths to prevent reflections and ensure data arrives intact.

Space Constraints and Multilayer Boards

As designs become more compact, fitting everything onto a single layer is often impossible. Multilayer boards, sometimes with 8, 12, or even 16 layers, are now common. This introduces the need for blind and buried vias routing to connect layers without wasting surface space. However, routing in multilayer boards adds complexity, as signals must transition smoothly between layers without interference.

Advanced Techniques in PCB Routing Software

Let’s break down the core advanced techniques that are transforming PCB design. These methods, supported by modern PCB routing software, empower engineers to tackle the toughest design challenges with precision.

1. Differential Pair Routing Rules for High-Speed Signals

Differential pair routing rules are essential for high-speed interfaces like USB, HDMI, and Ethernet, where data is transmitted over two traces carrying opposite signals. The goal is to keep these traces as identical as possible in length and spacing to minimize skew and electromagnetic interference (EMI).

Key guidelines for differential pair routing include:

- Length Matching: Ensure both traces in a pair are the same length, ideally within a tolerance of 5 mils (0.005 inches) for signals operating at 1 GHz or higher. This prevents timing mismatches.

- Consistent Spacing: Maintain a uniform gap between the traces (often 3x the trace width) to control impedance and reduce crosstalk.

- Avoid Sharp Bends: Use smooth curves or 45-degree angles instead of 90-degree turns to prevent signal reflections.

Modern PCB routing software automates much of this process by enforcing these rules and providing real-time feedback. Some tools even allow you to set specific constraints for differential pairs, ensuring compliance with standards like PCIe or USB 3.0.

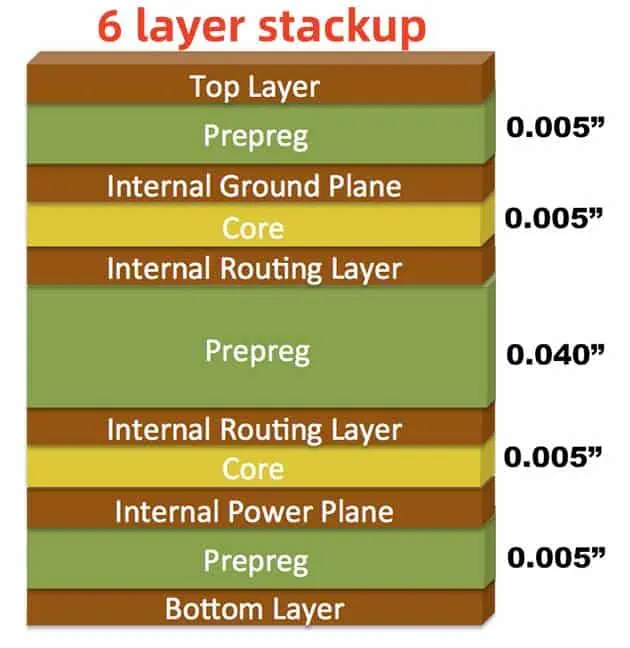

2. Blind and Buried Vias Routing for Multilayer Designs

In multilayer PCBs, vias are small holes that connect traces between layers. Traditional through-hole vias go all the way through the board, taking up valuable space on every layer. Blind and buried vias routing offers a smarter solution by connecting only specific layers, freeing up space for other components or traces.

- Blind Vias: These connect an outer layer to an inner layer but don’t go through the entire board. For example, a blind via might connect layer 1 to layer 2 in a 6-layer board, leaving layers 3 through 6 untouched.

- Buried Vias: These connect inner layers without reaching the surface, such as linking layer 2 to layer 3 in the same 6-layer board.

Using blind and buried vias reduces signal path lengths, which is critical for high-speed designs where every millimeter counts. However, they require precise planning in PCB routing software to avoid manufacturing issues. These vias also cost more to produce, so they’re typically used only when space or performance demands justify the expense.

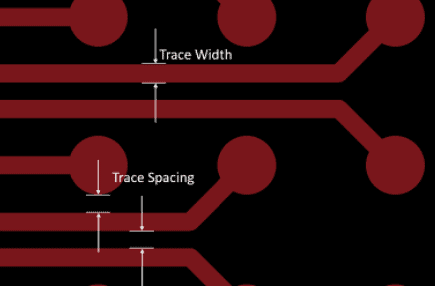

3. Trace Width Calculation Software for Power and Signal Integrity

The width of a trace determines how much current it can carry and affects its resistance and impedance. Too narrow, and a trace might overheat or fail to deliver enough power. Too wide, and it wastes valuable board space. Trace width calculation software integrated into PCB design tools helps engineers determine the optimal width based on specific parameters.

For example:

- Current Carrying Capacity: A trace carrying 1 Amp of current on a standard 1 oz copper layer might need to be at least 20 mils (0.02 inches) wide to avoid overheating, based on IPC-2221 standards.

- Signal Requirements: High-speed signals often require specific trace widths to match a target impedance, such as 50 ohms for many RF applications.

Advanced software tools use built-in calculators that factor in copper thickness, temperature rise, and board material to suggest the right trace width. This eliminates guesswork and ensures designs meet both electrical and thermal needs.

4. Impedance Matching Routing for Signal Integrity

Impedance matching routing is a cornerstone of high-speed PCB design. Impedance mismatches along a signal path can cause reflections, leading to data errors or signal loss. For instance, a typical single-ended trace for a digital signal might target an impedance of 50 ohms, while differential pairs often aim for 100 ohms.

To achieve proper impedance matching, consider these factors:

- Trace Geometry: The width and spacing of traces, as well as their distance from ground planes, directly affect impedance. A wider trace or closer ground plane lowers impedance.

- Board Material: The dielectric constant of the PCB material (often around 4.5 for FR-4) influences how signals propagate. High-frequency designs may use materials with lower dielectric constants for better performance.

- Layer Stackup: Ensure consistent layer spacing in multilayer boards to maintain uniform impedance across the design.

Advanced PCB routing software often includes impedance calculators and simulation tools to model signal behavior before manufacturing. This allows engineers to fine-tune trace dimensions and layer configurations to hit the desired impedance values.

Benefits of Using Advanced PCB Routing Software

Modern PCB routing software doesn’t just make these techniques possible—it makes them accessible. Here are some key benefits of leveraging these tools for advanced routing:

- Automation: Software can automatically enforce differential pair routing rules, calculate trace widths, and suggest via placements, saving hours of manual work.

- Simulation: Built-in simulation features let you test signal integrity and impedance before sending a design to production, reducing costly revisions.

- Error Checking: Real-time design rule checks (DRC) catch mistakes like improper spacing or unmatched trace lengths early in the process.

Best Practices for Implementing Advanced Routing Techniques

To get the most out of these advanced methods, follow these practical tips:

- Plan Ahead: Define your routing constraints, such as impedance targets or via types, before starting the layout. This prevents rework later.

- Use Ground Planes: Solid ground planes under high-speed traces reduce EMI and help with impedance matching routing.

- Optimize Layer Usage: In multilayer designs, reserve specific layers for power and ground to minimize interference with signal traces.

- Iterate and Test: Use simulation tools in your PCB routing software to test different routing scenarios and refine your design.

Conclusion: Revolutionizing PCB Design with Advanced Routing

The world of PCB design is evolving rapidly, and staying ahead means embracing advanced techniques like differential pair routing rules, blind and buried vias routing, trace width calculation software, and impedance matching routing. With the power of modern PCB routing software, engineers can tackle the most complex challenges, from high-speed signal integrity to compact multilayer layouts. By mastering these tools and techniques, you’ll not only improve the performance of your designs but also streamline the entire development process. Start integrating these advanced routing strategies into your next project and witness the revolution in PCB design firsthand.

ALLPCB

ALLPCB