If you're involved in small batch PCB production and wondering whether flying probe testing is the right choice for your low-volume manufacturing needs, the answer depends on your project requirements. Flying probe testing is a flexible, cost-effective method ideal for prototypes and small batches, as it doesn't require custom fixtures and offers quick setup for testing electrical performance. However, it may not be the best fit for high-volume production due to slower testing speeds. In this comprehensive guide, we'll dive deep into the specifics of flying probe testing for low volume, explore its economics, and help you decide if it aligns with your manufacturing goals.

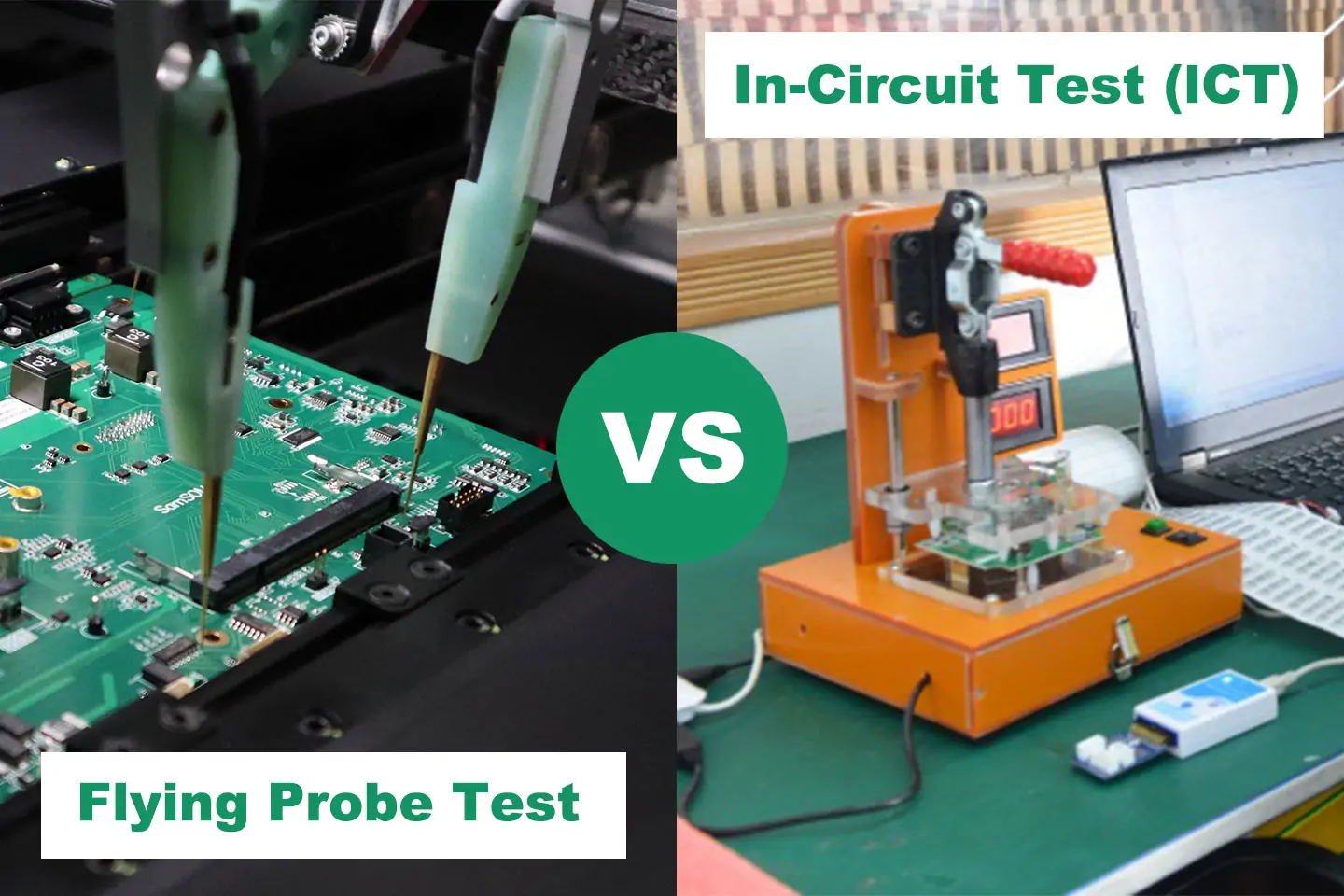

What Is Flying Probe Testing in PCB Manufacturing?

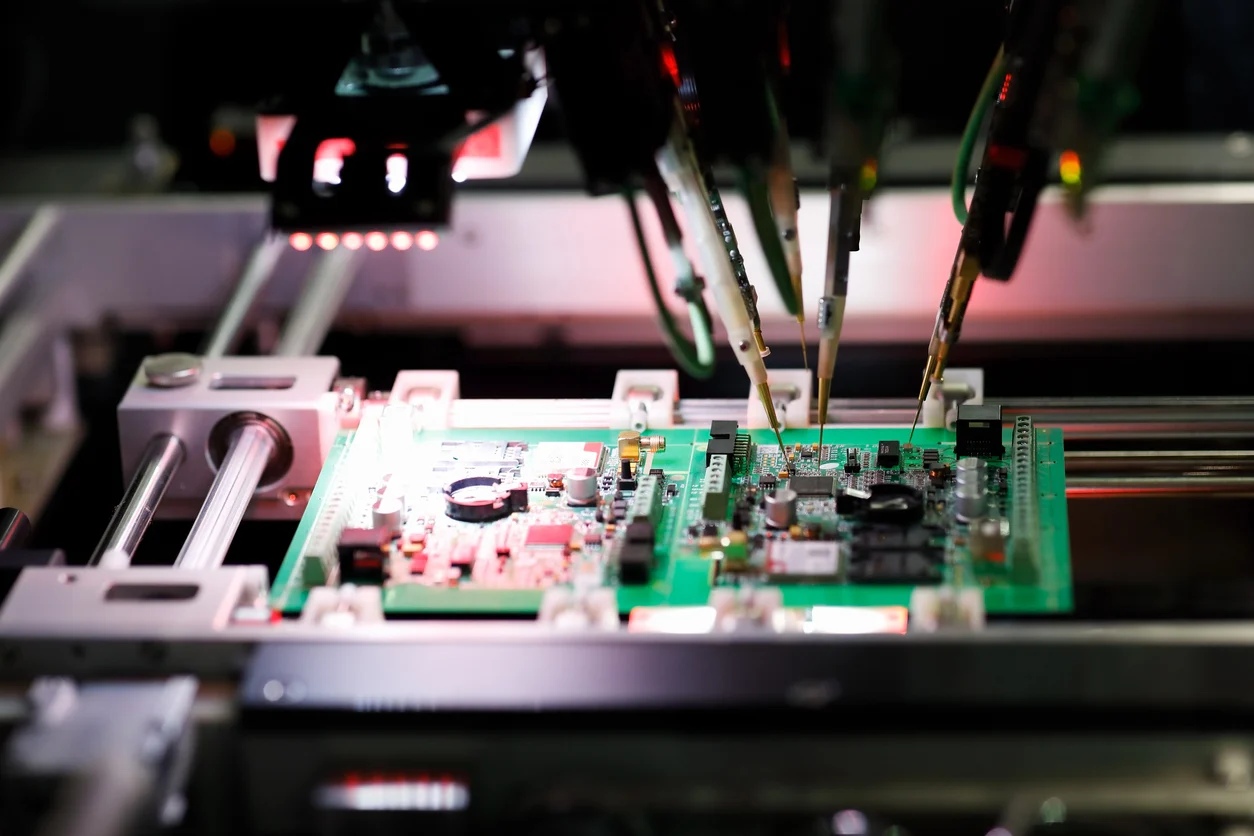

Flying probe testing (FPT) is an automated testing method used to check the electrical functionality of printed circuit boards (PCBs). Unlike traditional testing methods that rely on a fixed bed of nails fixture, FPT uses movable probes that "fly" across the board to test various points for connectivity, shorts, opens, and component values. This technology is particularly suited for small batch PCB testing because of its adaptability and minimal setup requirements.

The probes in FPT systems are controlled by sophisticated software that directs them to specific test points on the PCB. These systems can measure resistance, capacitance, and other electrical properties with high precision, ensuring that your board meets design specifications. For low-volume production, this method shines by eliminating the need for costly custom fixtures, which are often impractical for small runs or frequent design changes.

Why Choose Flying Probe Testing for Low Volume Production?

When you're dealing with small batch PCB production, efficiency and cost control are critical. Flying probe testing offers several advantages that make it a go-to choice for low-volume manufacturing. Let's break down the key benefits:

1. No Custom Fixtures Needed

Traditional testing methods like in-circuit testing (ICT) require custom fixtures tailored to each PCB design. These fixtures can cost thousands of dollars and take weeks to develop, making them uneconomical for small batches. Flying probe testing, on the other hand, uses programmable probes that adapt to any board layout without additional hardware, saving both time and money.

2. Quick Setup and Turnaround

For low-volume runs or prototypes, speed is often a priority. Setting up a flying probe tester typically takes just a few hours, as it only requires loading the PCB design data into the system. This rapid setup allows manufacturers to test and iterate designs quickly, which is essential for projects with tight deadlines or frequent revisions.

3. High Flexibility for Design Changes

Small batch production often involves testing multiple design iterations. Since flying probe testing doesn't rely on fixed fixtures, it can easily accommodate changes in PCB layouts. This flexibility is a significant advantage for engineers working on prototypes or early-stage products where designs are still evolving.

4. Cost-Effective for Small Runs

The economics of flying probe testing are particularly favorable for low-volume manufacturing. While the per-unit testing cost may be higher compared to high-volume methods, the absence of fixture costs and the ability to test small quantities without significant upfront investment make it a budget-friendly option for small batches.

How Does Flying Probe Testing Work?

Understanding the mechanics of flying probe testing can help you appreciate its suitability for small batch PCB testing. Here's a step-by-step overview of the process:

- Design Data Input: The PCB design file, often in a format like Gerber or CAD, is uploaded into the flying probe testing system. This file contains information about test points, component locations, and expected electrical values.

- Probe Movement: The system's robotic probes move across the PCB surface, guided by the software to contact specific test points. Modern systems often have multiple probes (typically 2 to 8) working simultaneously to speed up the process.

- Electrical Testing: The probes measure electrical properties such as continuity, resistance (often down to milliohms), and capacitance (in picofarads). They can detect issues like open circuits, short circuits, or incorrect component values.

- Results Analysis: The system compiles the test data and generates a report highlighting any faults or deviations from the design specifications. This report helps manufacturers identify and fix issues before the boards move to assembly or shipping.

For small batch production, this process is ideal because it doesn't require physical retooling between different PCB designs. Whether you're testing 5 boards or 50, the system can adapt without additional costs or delays.

Flying Probe Testing Economics: Cost Breakdown for Low Volume

One of the most critical factors in choosing a testing method for small batch PCB production is cost. Let's explore the economics of flying probe testing to see how it impacts your bottom line in low-volume manufacturing.

Upfront Costs

Unlike traditional ICT, which requires an initial investment of $5,000 to $15,000 for custom fixtures per design, flying probe testing has virtually no upfront costs beyond the testing service itself. This makes it an attractive option for projects with limited budgets or one-off designs.

Per-Unit Testing Cost

Flying probe testing typically costs more per unit than high-volume testing methods due to its slower speed. On average, testing a single PCB with FPT might range from $10 to $50, depending on the complexity of the board and the number of test points. For a small batch of 10 to 100 boards, this cost can add up but remains manageable compared to fixture-based alternatives.

Time Efficiency

While flying probe testing is slower than ICT for large volumes (testing a single board can take 5 to 15 minutes depending on complexity), the time saved on setup and fixture development often outweighs this drawback for low-volume runs. For instance, setting up an ICT fixture might take 2-3 weeks, whereas FPT can be ready in under a day.

Long-Term Savings

For small batch PCB testing, the ability to reuse the same testing equipment across multiple designs without additional investment leads to significant long-term savings. This is especially true for companies that frequently produce prototypes or small runs with varying designs.

Advantages and Limitations of Flying Probe Testing for Small Batches

While flying probe testing offers many benefits for low-volume manufacturing, it's not without its limitations. Here's a balanced look at its pros and cons to help you decide if it's right for your project.

Advantages

- Fixtureless Design: No need for expensive custom fixtures, making it ideal for small batch PCB testing.

- High Precision: Modern systems can test fine-pitch components and complex boards with accuracy, often detecting faults down to 0.1 ohms.

- Adaptability: Easily handles design changes and multiple board types without additional setup.

- Reduced Lead Time: Faster setup means quicker turnaround for prototypes and small runs.

Limitations

- Slower Testing Speed: Not suitable for high-volume production, as testing each board takes longer compared to fixture-based methods.

- Limited Test Coverage: May not test certain components like high-frequency signals or complex power circuits as effectively as other methods.

- Higher Per-Unit Cost: More expensive per board than mass-production testing solutions, though overall costs remain lower for small batches due to no fixture expenses.

Applications of Flying Probe Testing in Low-Volume Manufacturing

Flying probe testing is widely used in scenarios where flexibility and cost control are more important than speed. Here are some common applications in small batch PCB production:

- Prototyping: Engineers use FPT to validate designs before moving to full-scale production, ensuring electrical performance without investing in fixtures.

- Small Batch Runs: For production runs of 10 to 500 units, FPT provides a cost-effective way to ensure quality without the overhead of traditional testing setups.

- Complex Boards: PCBs with high-density layouts or fine-pitch components benefit from the precision of flying probe systems.

- Design Validation: During the R&D phase, FPT helps identify design flaws early, saving time and resources in later stages.

Is Flying Probe Testing Right for Your Small Batch PCB Production?

Deciding whether flying probe testing fits your low-volume manufacturing needs comes down to a few key considerations:

- Batch Size: If you're producing fewer than 500 units or focusing on prototypes, FPT is likely a good fit due to its low setup costs and flexibility.

- Budget Constraints: If avoiding upfront costs for fixtures is a priority, flying probe testing offers a more economical approach for small batches.

- Design Complexity: For intricate designs with frequent changes, the adaptability of FPT can save significant time and resources.

- Time Sensitivity: If you need quick turnaround without waiting for custom tooling, FPT's fast setup is a major advantage.

However, if your production volume starts to scale beyond small batches, or if you require testing for very high-speed signals (above 1 GHz, for instance), you might need to explore other testing methods or combine FPT with additional quality checks.

Optimizing Flying Probe Testing for Your Manufacturing Process

To get the most out of flying probe testing in small batch PCB production, consider these practical tips:

- Design for Testability: Ensure your PCB layout includes accessible test points to make the process smoother and more accurate. Aim for test points spaced at least 2 mm apart for optimal probe contact.

- Collaborate with Your Manufacturer: Work closely with your testing provider to provide accurate design files and specify critical test parameters, reducing the risk of errors.

- Batch Testing Strategically: Group similar designs or revisions into a single testing session to maximize efficiency and minimize setup time.

- Review Test Reports Thoroughly: Use the detailed reports generated by FPT systems to identify recurring issues in your designs, improving future iterations.

Conclusion: Making the Right Choice for Low-Volume PCB Testing

Flying probe testing stands out as a powerful solution for small batch PCB production, offering unmatched flexibility, cost savings on fixtures, and quick setup times. Its economics make it particularly appealing for low-volume manufacturing, where traditional testing methods often fall short due to high upfront costs. While it may not suit high-volume runs or highly specialized testing needs, for prototypes, small batches, and evolving designs, it provides a reliable and efficient way to ensure quality.

By understanding the benefits, limitations, and applications of flying probe testing, you can make an informed decision about whether it’s the right fit for your project. With its ability to adapt to various designs and deliver precise results without breaking the bank, it’s a tool worth considering for any engineer or manufacturer focused on small-scale PCB production.

ALLPCB

ALLPCB