If you're stepping into the world of PCB design, you've likely heard of RoHS compliance. But what exactly is it, and why does it matter for your projects? RoHS, or Restriction of Hazardous Substances, is a directive that limits the use of specific harmful materials in electronic products, including printed circuit boards (PCBs). In this beginner's guide, we'll break down the RoHS compliance definition, explore RoHS restricted substances for PCB, dive into the RoHS directive for PCB design, provide a RoHS compliance checklist for designers, and highlight RoHS compliant materials for PCB. Whether you're a hobbyist or a professional engineer, this guide will help you navigate the essentials of RoHS compliance with clarity and confidence.

What is RoHS Compliance? A Simple Definition

RoHS stands for Restriction of Hazardous Substances. It’s a regulation first introduced by the European Union (EU) in 2003 to reduce the environmental and health risks posed by hazardous materials in electrical and electronic equipment (EEE). The directive applies to products sold in the EU market and has been adopted or mirrored in many other regions worldwide. For PCB designers, RoHS compliance definition means ensuring that your boards and components do not contain restricted substances above specified limits, making your designs safer and more environmentally friendly.

RoHS compliance isn't just a legal requirement for selling in certain markets; it’s also a commitment to sustainability. By following these guidelines, designers contribute to reducing e-waste toxicity and protecting both people and the planet. Let’s dive deeper into the specifics of this directive and how it impacts PCB design.

Understanding the RoHS Directive for PCB Design

The RoHS directive for PCB design is a set of rules that governs the materials and processes used in creating electronic components. Originally launched as Directive 2002/95/EC, it has evolved over the years, with the latest version often referred to as RoHS 3 (Directive 2015/863). This directive applies to all electrical and electronic equipment, including PCBs, sold within the EU. It’s crucial for designers to understand these rules to ensure their products can access this market.

The directive focuses on restricting specific hazardous substances that can be harmful during manufacturing, use, or disposal. For PCB designers, this means selecting materials and components that meet RoHS standards and working with manufacturers who adhere to these guidelines. Non-compliance can result in restricted market access, fines, or product recalls, which can be costly for any business or individual.

Compliance also involves documentation. Designers must often provide declarations or certificates proving that their PCBs meet RoHS standards. This might include test reports or supplier statements confirming that components are free from restricted substances. Staying updated with the latest amendments to the directive, such as the addition of new substances, is also essential for maintaining compliance over time.

RoHS Restricted Substances for PCB: What You Need to Know

One of the core elements of RoHS compliance is avoiding the use of certain hazardous materials. The list of RoHS restricted substances for PCB includes ten specific chemicals, each with a maximum concentration limit (usually 0.1% by weight, or 1000 ppm, except for Cadmium, which is 0.01% or 100 ppm). These limits apply to each homogeneous material in the product, meaning individual components like solder, coatings, or substrates must comply. Here’s the full list of restricted substances under RoHS 3:

- Lead (Pb): Commonly found in solder and component terminations. Limit: 0.1%.

- Mercury (Hg): Used in some switches and relays. Limit: 0.1%.

- Cadmium (Cd): Found in batteries and surface finishes. Limit: 0.01%.

- Hexavalent Chromium (Cr VI): Used in corrosion-resistant coatings. Limit: 0.1%.

- Polybrominated Biphenyls (PBB): Flame retardants in plastics. Limit: 0.1%.

- Polybrominated Diphenyl Ethers (PBDE): Another type of flame retardant. Limit: 0.1%.

- Bis(2-Ethylhexyl) Phthalate (DEHP): Plasticizer in cables and insulation. Limit: 0.1%.

- Benzyl Butyl Phthalate (BBP): Plasticizer in polymers. Limit: 0.1%.

- Dibutyl Phthalate (DBP): Used in adhesives and coatings. Limit: 0.1%.

- Diisobutyl Phthalate (DIBP): Similar to other phthalates, used in plastics. Limit: 0.1%.

For PCB designers, lead is often the most relevant substance to watch out for, as traditional solder alloys like tin-lead (Sn-Pb) exceed the allowed limit. Switching to lead-free solder, such as tin-silver-copper (SAC) alloys, is a common solution. Additionally, components like connectors or resistors may contain restricted substances in their plating or housing, so careful selection is necessary.

Why RoHS Compliance Matters for PCB Designers

Adhering to RoHS standards is not just about meeting legal requirements; it also brings several benefits. First, it ensures market access. If you’re designing PCBs for products that will be sold in the EU or other regions adopting similar regulations, compliance is non-negotiable. Without it, your products could be barred from these markets.

Second, RoHS compliance promotes safety. The restricted substances are hazardous to human health and the environment. For example, lead exposure can cause neurological damage, while mercury can contaminate water sources. By designing with safer materials, you contribute to a healthier world.

Finally, compliance can enhance your reputation. Customers and partners often prefer working with designers and manufacturers who prioritize sustainability. Demonstrating a commitment to RoHS standards can set you apart in a competitive industry.

RoHS Compliance Checklist for Designers: Your Step-by-Step Guide

Navigating RoHS compliance can feel overwhelming, especially for beginners. To simplify the process, here’s a practical RoHS compliance checklist for designers to ensure your PCB designs meet the necessary standards:

- Understand the Requirements: Familiarize yourself with the RoHS directive and its list of restricted substances. Keep up with updates, as new substances may be added over time.

- Select Compliant Components: Source components from suppliers who provide RoHS certificates or declarations of compliance. Verify that resistors, capacitors, connectors, and other parts meet the standards.

- Choose Lead-Free Solder: Opt for lead-free solder alloys like SAC305 (3% silver, 0.5% copper, balance tin), which has a melting point of around 217°C, compared to 183°C for traditional tin-lead solder. Ensure compatibility with your assembly process.

- Check Surface Finishes: Use RoHS-compliant finishes like immersion silver (Ag), immersion tin (Sn), or ENIG (Electroless Nickel Immersion Gold) instead of finishes containing restricted substances like lead or cadmium.

- Verify Substrate Materials: Confirm that PCB laminates and other materials do not contain restricted flame retardants like PBB or PBDE. FR-4 materials, for instance, are often available in RoHS-compliant versions.

- Partner with Compliant Manufacturers: Work with PCB fabrication and assembly services that adhere to RoHS standards. Request documentation to confirm their processes are compliant.

- Maintain Documentation: Keep records of compliance certificates, test reports, and supplier declarations. This paperwork is crucial for audits or customer inquiries.

- Test When Necessary: If there’s uncertainty about a component or material, consider testing for restricted substances using methods like X-ray fluorescence (XRF) spectroscopy, which can detect elements like lead or cadmium down to parts-per-million levels.

Following this checklist will help ensure that your designs are fully compliant, reducing the risk of issues down the line. It’s always better to address compliance early in the design phase rather than retrofitting solutions after production.

RoHS Compliant Materials for PCB: Making the Right Choices

Selecting RoHS compliant materials for PCB is a critical step in achieving compliance. The materials you choose for substrates, solder, and finishes directly impact whether your design meets RoHS standards. Here are some common choices for compliant materials:

- Substrate Materials: Standard FR-4 laminates are widely used and available in RoHS-compliant versions that avoid restricted flame retardants. Look for materials certified as halogen-free to ensure the absence of PBB and PBDE.

- Solder Materials: Lead-free solders are essential. SAC alloys, like SAC305, are popular due to their reliability and compatibility with most assembly processes. They offer good thermal and mechanical properties, though they require higher reflow temperatures (typically 240-260°C) compared to traditional solders.

- Surface Finishes: Options like immersion silver, immersion tin, and ENIG are RoHS-compliant alternatives to lead-containing finishes. ENIG, for instance, provides excellent corrosion resistance and solderability, with a typical nickel layer thickness of 3-6 micrometers and a gold layer of 0.05-0.1 micrometers.

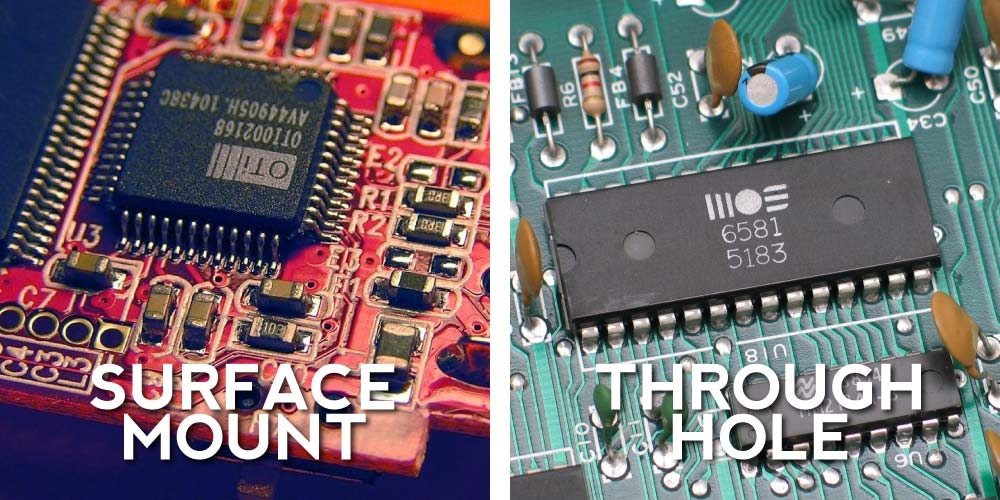

- Components and Connectors: Ensure that all components, from ICs to connectors, are labeled as RoHS-compliant by the manufacturer. Pay attention to plating materials, as some older connectors may use cadmium or lead-based finishes.

Working with suppliers who prioritize RoHS compliance can make material selection easier. Always request material safety data sheets (MSDS) or compliance statements to confirm that the materials meet the necessary standards.

Challenges in Achieving RoHS Compliance for PCB Design

While the benefits of RoHS compliance are clear, there are challenges to consider. Transitioning to lead-free solder, for example, can impact the reliability of solder joints due to higher melting points and different mechanical properties. This might require adjustments in reflow profiles or even redesigning boards to handle thermal stress. For instance, lead-free soldering often peaks at temperatures around 260°C, compared to 220°C for tin-lead solder, which can stress components if not managed properly.

Another challenge is cost. RoHS-compliant materials and components can be more expensive, especially for small-scale projects. Additionally, verifying compliance across a supply chain can be time-consuming, particularly when sourcing from multiple vendors. Despite these hurdles, the long-term advantages of compliance—such as market access and sustainability—outweigh the initial difficulties.

Tips for Staying Updated on RoHS Regulations

RoHS regulations are not static; they evolve as new substances are identified as hazardous. To stay compliant, regularly check updates from official sources like the European Commission’s website. Joining industry forums or subscribing to newsletters from regulatory bodies can also keep you informed about changes. Additionally, collaborating with manufacturing partners who prioritize compliance can help ensure that your designs remain aligned with the latest standards.

How ALLPCB Supports RoHS Compliance

At ALLPCB, we understand the importance of RoHS compliance in PCB design. Our services are tailored to help designers meet these standards without hassle. We offer a wide range of RoHS-compliant materials, from lead-free solders to halogen-free substrates, ensuring that your boards meet regulatory requirements. Our team also provides documentation support, so you can confidently present compliance records to customers or regulators. With a commitment to quality and sustainability, we’re here to simplify the process for you.

Conclusion: Embracing RoHS Compliance in PCB Design

RoHS compliance is a vital aspect of modern PCB design, ensuring that your products are safe, sustainable, and market-ready. By understanding the RoHS compliance definition, adhering to the RoHS directive for PCB design, avoiding RoHS restricted substances for PCB, following a RoHS compliance checklist for designers, and selecting RoHS compliant materials for PCB, you can create designs that meet global standards. While challenges like cost and material transitions exist, the benefits of compliance far outweigh the drawbacks.

Start integrating RoHS principles into your workflow today. With the right knowledge and support, achieving compliance is not only achievable but also a step toward a better future for electronics and the environment. Trust partners like ALLPCB to guide you through the process, ensuring your designs are both innovative and responsible.

ALLPCB

ALLPCB