If you're looking to design a printed circuit board (PCB) for wearable electronics using open-source software, KiCad is an excellent choice. This powerful, free tool allows you to create professional-grade PCB layouts for innovative wearable devices like smartwatches, fitness trackers, or medical sensors. In this comprehensive tutorial, we’ll guide you through the process of designing a wearable PCB with KiCad, focusing on practical steps and tips tailored for wearable electronics. Whether you're a beginner or an experienced engineer, this guide will help you master KiCad PCB design for wearable applications using open-source PCB design software.

Why Choose KiCad for Wearable PCB Design?

KiCad is a free, open-source PCB design software that offers robust features for schematic capture, PCB layout, and 3D visualization. Unlike many paid tools, it has no limitations on board size or layer count, making it ideal for both hobbyists and professionals working on wearable electronics. Wearable devices often require compact designs, flexible layouts, and precise component placement—challenges that KiCad handles effectively with its versatile toolset.

Additionally, KiCad’s active community provides extensive resources, libraries, and plugins, ensuring you have support for creating intricate designs. For wearable PCB projects, where space and efficiency are critical, KiCad’s ability to handle tight layouts and custom footprints is a game-changer.

Understanding Wearable Electronics Design Challenges

Before diving into the tutorial, it’s important to understand the unique challenges of designing PCBs for wearable electronics. These devices must be small, lightweight, and often flexible to fit comfortably on the body. Here are some key considerations:

- Size Constraints: Wearable devices like fitness bands or smart rings demand ultra-compact PCB layouts, often under 30mm x 30mm.

- Power Efficiency: Battery life is critical, so designs must minimize power consumption, often targeting currents below 10mA in sleep mode.

- Flexibility: Some wearables use flexible or rigid-flex PCBs to conform to curved surfaces, requiring specific design rules.

- Signal Integrity: High-frequency signals, such as Bluetooth at 2.4 GHz, need careful routing to avoid interference in tight spaces.

- Heat Dissipation: Components must manage heat effectively in enclosed, skin-contact designs, often keeping temperatures below 40°C.

With these challenges in mind, let’s explore how KiCad can help you address them step by step.

Getting Started with KiCad for PCB Design

If you’re new to KiCad, the first step is to download and install the software from its official website. It’s available for Windows, macOS, and Linux, ensuring accessibility across platforms. Once installed, familiarize yourself with its main components: the schematic editor (Eeschema), PCB layout editor (Pcbnew), and 3D viewer.

For this tutorial, we’ll assume you have a basic understanding of electronics design. If not, KiCad offers detailed documentation and beginner guides to help you get up to speed. Let’s start by setting up a new project for a wearable device, such as a simple fitness tracker with a microcontroller, sensors, and Bluetooth connectivity.

Step 1: Creating a Schematic in KiCad

The schematic is the foundation of your PCB design. In KiCad’s schematic editor, you’ll define the components and their connections for your wearable device. Follow these steps:

- Add Components: Use the component library to add parts like a microcontroller (e.g., an ARM Cortex-M0 with a 32-bit architecture), a heart rate sensor, and a Bluetooth module. KiCad’s library includes thousands of symbols, but you can also create custom ones if needed.

- Wire Connections: Connect components using wires, ensuring proper power and ground connections. For wearables, include a small lithium-ion battery input, typically 3.7V, with protection circuitry.

- Annotate and Check: Assign reference designators to components and run an Electrical Rules Check (ERC) to catch errors like unconnected pins.

For wearable designs, keep power traces short to reduce resistance, aiming for trace widths of at least 0.5mm for currents around 500mA. Also, group related components (like sensors and their supporting capacitors) close together to minimize noise.

Step 2: Assigning Footprints for PCB Layout

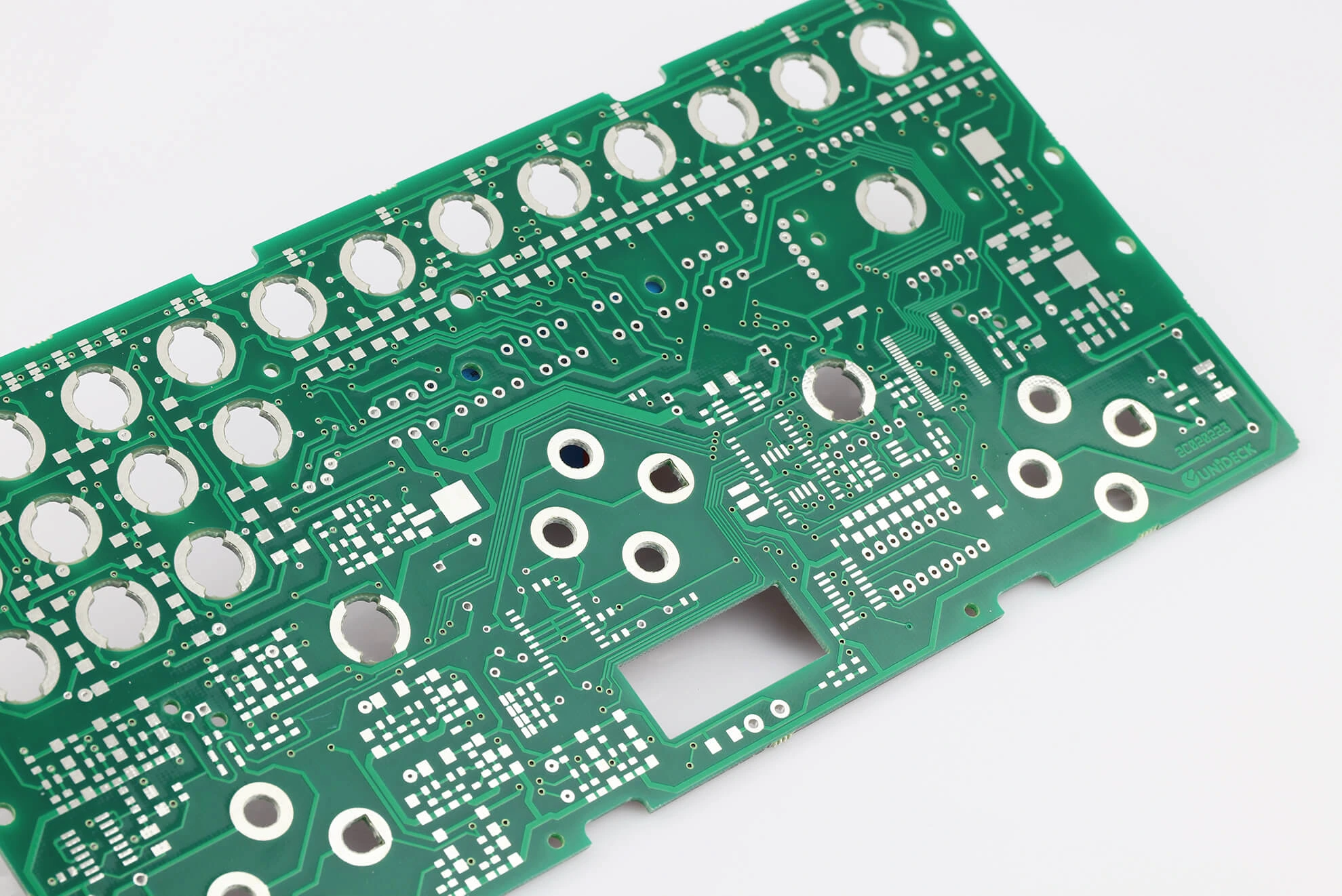

Once your schematic is ready, link each component to its physical footprint. Footprints define how components appear on the PCB, including pad sizes and shapes. In KiCad, use the “Assign Footprints” tool to match symbols to footprints from the library. For wearables, prioritize small surface-mount device (SMD) packages like 0402 or 0201 for resistors and capacitors to save space.

If a specific footprint isn’t available, KiCad allows you to design custom footprints using the Footprint Editor. For instance, a custom sensor module might require pads spaced at 0.5mm pitch for fine connections.

Step 3: Designing the PCB Layout in KiCad

Now, move to the PCB layout editor in KiCad to arrange components and route traces. This step is critical for wearable electronics, where every millimeter counts. Here’s how to proceed:

- Set Board Dimensions: Define the board outline, keeping it small—say, 25mm x 20mm for a wristband sensor. Use the “Edge.Cuts” layer to draw the shape.

- Place Components: Position components logically, placing the microcontroller centrally and sensors near the edge for skin contact. Keep high-frequency components like Bluetooth modules away from sensitive analog parts to avoid interference.

- Route Traces: Route power and ground first, using a ground plane to reduce noise. For high-speed signals like I2C or SPI (operating at 400 kHz to 1 MHz), keep traces short and avoid sharp 90-degree bends—use 45-degree angles instead.

- Design Rules Check (DRC): Run a DRC to ensure clearances meet manufacturing standards, typically 0.2mm for trace spacing and 0.3mm for via-to-pad clearance.

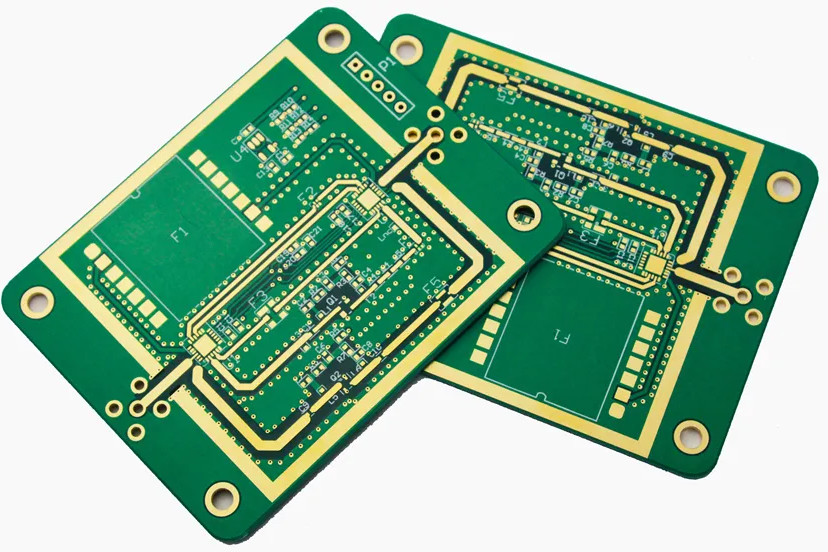

For wearable PCBs, consider a 4-layer board if space is tight. Layers can separate power, ground, and signal traces, reducing crosstalk. A typical stack-up might have a total thickness of 0.8mm, suitable for lightweight designs.

Step 4: Addressing Wearable-Specific Design Needs

Wearable electronics often require additional considerations during PCB design. Here are some tips to optimize your layout using KiCad:

- Flexible PCBs: If your wearable needs a flexible board, define bendable areas in the layout. KiCad supports custom board outlines, so draw curves where flexibility is needed. Use thinner substrates, like 0.1mm polyimide, in your design notes.

- Antenna Design: For Bluetooth or Wi-Fi connectivity, integrate a trace antenna or reserve space for a chip antenna. Maintain a clearance of at least 5mm around the antenna to avoid signal degradation at 2.4 GHz.

- Thermal Management: Add thermal vias under heat-generating components like voltage regulators. Aim for via diameters of 0.3mm to dissipate heat effectively, keeping skin-contact areas below 38°C.

KiCad’s 3D viewer is handy here. Use it to visualize how your PCB fits into a wearable enclosure, ensuring no components protrude uncomfortably.

Step 5: Generating Manufacturing Files

Once your design is complete, generate the files needed for manufacturing. In KiCad, use the “Plot” feature to export Gerber files for each layer (copper, silkscreen, solder mask, etc.). Also, export a drill file for vias and holes. Typical manufacturing tolerances for wearable PCBs include a minimum hole size of 0.25mm and trace width of 0.15mm.

Double-check your files using KiCad’s Gerber viewer to ensure no errors, such as missing layers or misaligned pads. Include a Bill of Materials (BOM) file listing all components, specifying part numbers and quantities for assembly.

Step 6: Testing and Iteration

After manufacturing, test your wearable PCB for functionality. Check power delivery, ensuring voltage levels stay within 5% of the target (e.g., 3.3V for most microcontrollers). Verify sensor accuracy and wireless connectivity range—Bluetooth should maintain a stable connection up to 10 meters in open space.

If issues arise, such as signal noise or overheating, revisit your KiCad design. Adjust trace lengths, add decoupling capacitors (typically 0.1μF near IC pins), or reposition components. KiCad makes iteration easy with its integrated schematic and layout editors.

Tips for Optimizing Wearable PCB Designs in KiCad

To wrap up, here are some additional tips for creating efficient wearable electronics using open-source PCB design software like KiCad:

- Use Libraries Wisely: Leverage KiCad’s vast library of pre-made symbols and footprints to save time. Update libraries regularly for the latest components.

- Simulate First: Although KiCad doesn’t include built-in simulation, integrate with external open-source tools to simulate circuits before layout, ensuring signal integrity at frequencies like 2.4 GHz.

- Community Support: Join KiCad forums and user groups for advice on wearable-specific challenges, such as designing for IP67 water resistance.

- Keep It Simple: Avoid overcomplicating designs. For wearables, prioritize essential features over adding unnecessary components that increase size and power draw.

Conclusion: Mastering Wearable PCB Design with KiCad

Designing PCBs for wearable electronics is a rewarding challenge, and KiCad provides all the tools you need as an open-source PCB design software. From creating schematics to laying out compact boards and generating manufacturing files, this tutorial has walked you through the essentials of KiCad PCB design tailored for wearable applications. By addressing size constraints, power efficiency, and signal integrity, you can create innovative devices that meet modern demands.

Start your next wearable project with KiCad today, and take advantage of its flexibility and community support to bring your ideas to life. With practice, you’ll master the art of designing efficient, reliable PCBs for the fast-growing field of wearable electronics.

ALLPCB

ALLPCB