When designing a 14-layer PCB, selecting the right materials is critical to ensure performance, reliability, and cost-effectiveness. The choice often comes down to two popular options: FR-4 and high-frequency materials like those known for superior signal integrity. This blog post provides a detailed comparison of these materials, focusing on key factors such as dielectric constant, thermal stability, and suitability for high-frequency applications. Whether you're working on complex electronics or high-speed designs, understanding these materials will help you make an informed decision for your 14-layer PCB project.

Why Material Selection Matters for 14-Layer PCBs

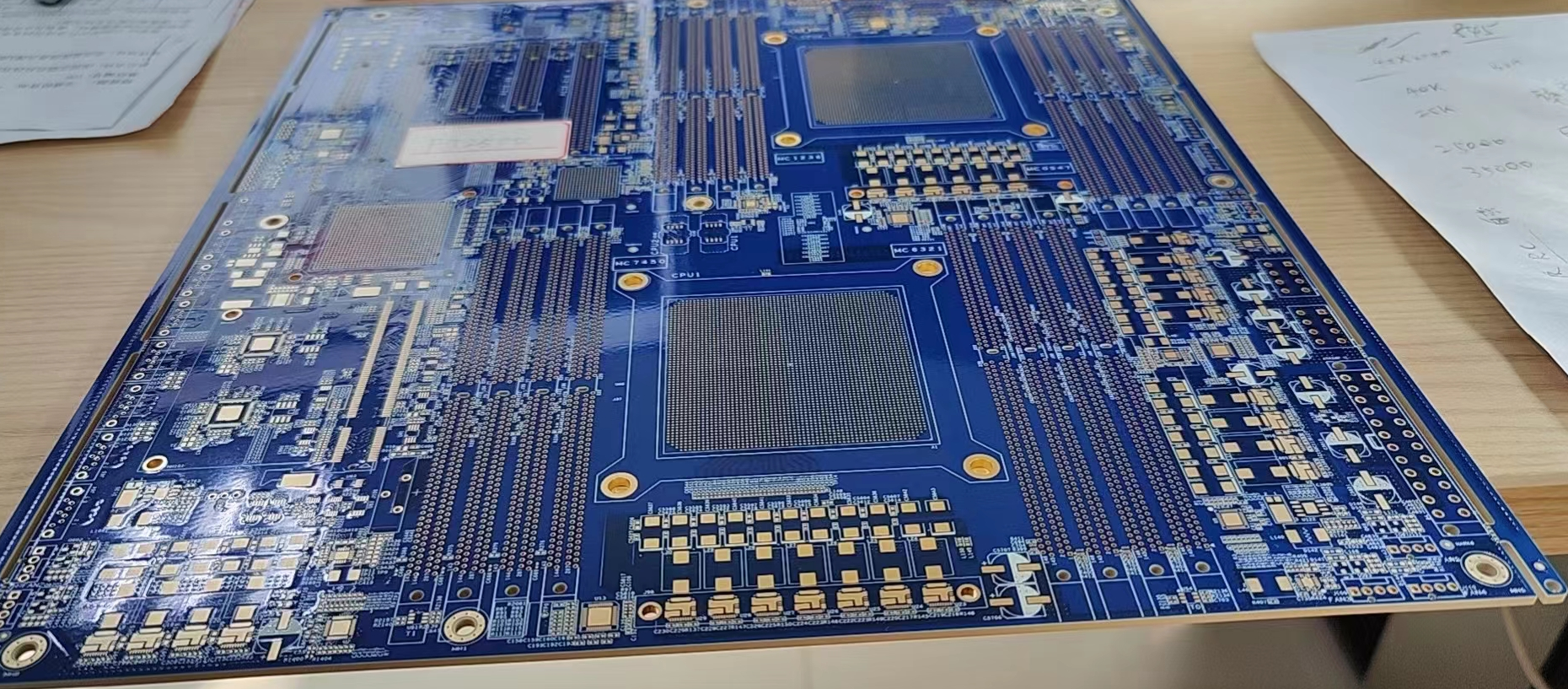

A 14-layer PCB is a complex, multilayer board often used in advanced applications like telecommunications, aerospace, and high-speed digital circuits. With so many layers, the material you choose directly impacts signal integrity, thermal management, and overall board performance. A poor material choice can lead to issues like signal loss, impedance mismatches, or even board failure under stress. That’s why understanding the properties of different PCB laminates is essential before starting your design.

In this guide, we'll compare the most common material, FR-4, with high-frequency laminates often used for specialized applications. We'll dive into their properties, advantages, and limitations, helping you decide which is best for your specific needs in 14-layer PCB materials selection.

Understanding 14-Layer PCB Materials: The Basics

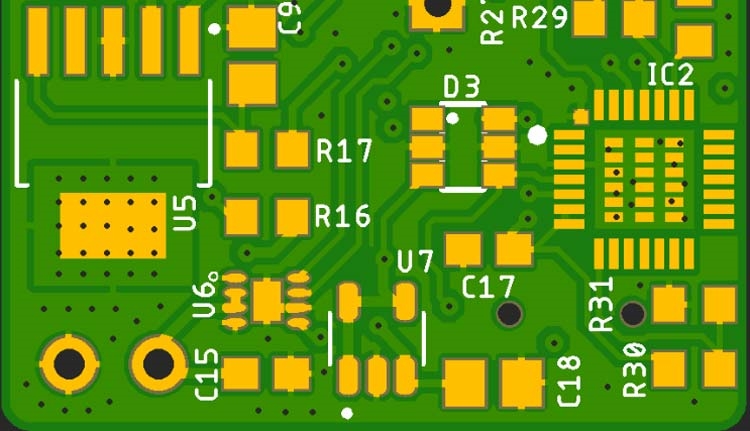

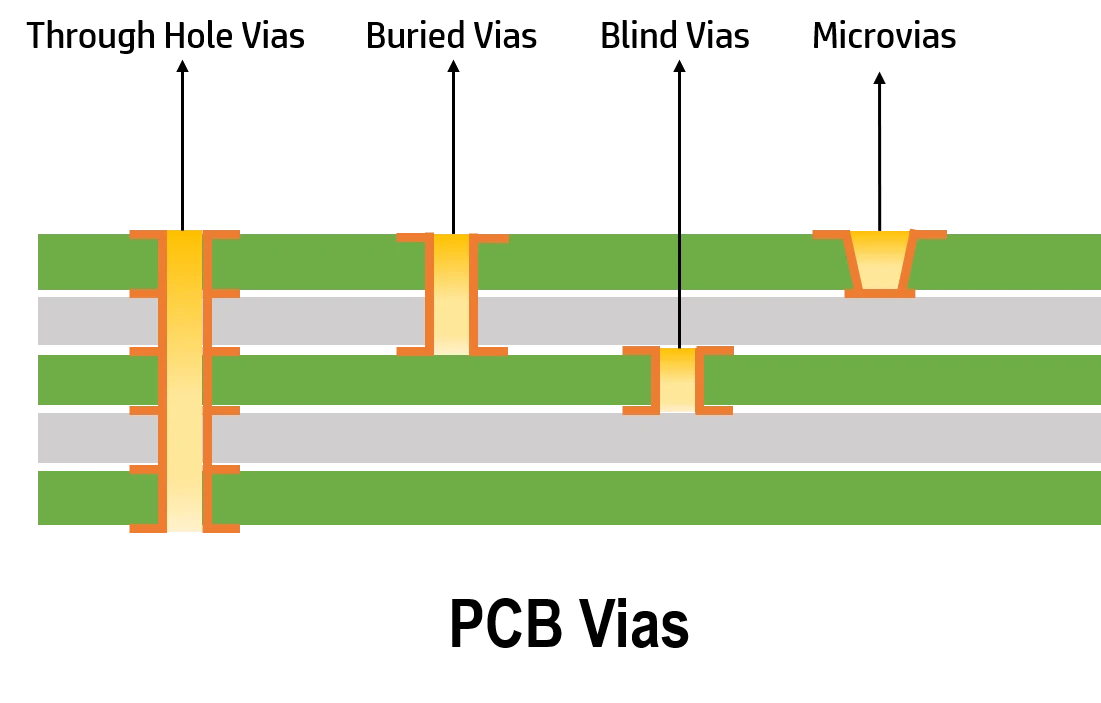

A 14-layer PCB consists of multiple layers of conductive copper and insulating material stacked together. The insulating material, or laminate, plays a huge role in how the board performs. Two main categories of materials are often considered for such designs:

- FR-4: A widely used, cost-effective laminate made of woven fiberglass and epoxy resin. It’s the standard for many PCB designs due to its balance of performance and affordability.

- High-Frequency Materials: Specialized laminates designed for applications requiring low signal loss and stable performance at high frequencies. These materials often outperform FR-4 in demanding environments.

Choosing between these materials depends on your project’s requirements, including frequency range, thermal demands, and budget constraints. Let’s break down the key properties to consider when selecting PCB laminates for a 14-layer board.

Key Factors in PCB Laminate Selection for 14-Layer Boards

When deciding on materials for a 14-layer PCB, several technical properties come into play. Below are the most important factors to evaluate:

1. Dielectric Constant (Dk) in PCB Materials

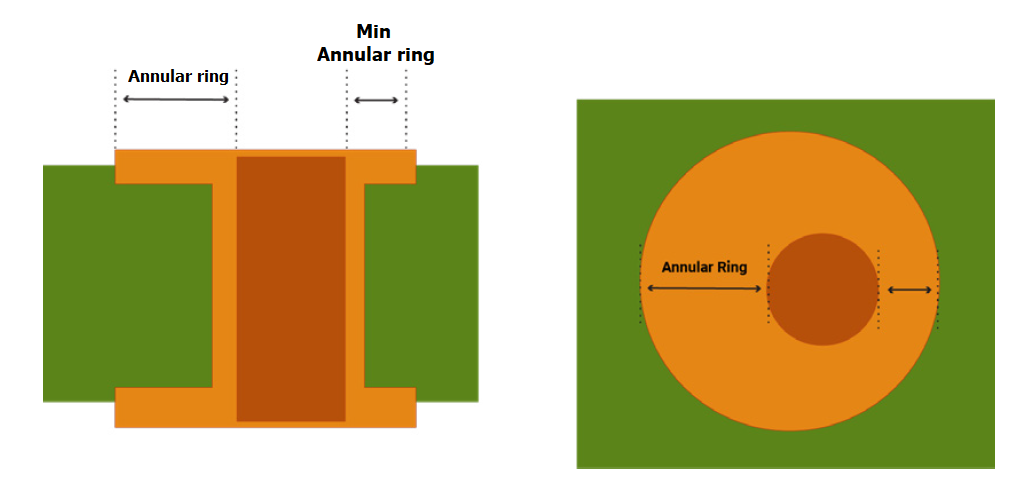

The dielectric constant (Dk) measures how much a material can store electrical energy in an electric field. It affects signal speed and impedance in a PCB. For a 14-layer board with tight impedance control, the Dk value is critical.

- FR-4: Has a Dk value of approximately 4.5. This is suitable for many standard applications but can vary slightly with temperature and frequency, potentially causing signal integrity issues in high-speed designs.

- High-Frequency Materials: Offer a wider range of Dk values, often between 2.2 and 10, depending on the specific formulation. They provide more stable Dk values across frequencies, making them ideal for high-frequency PCB materials used in RF and microwave applications.

For a 14-layer PCB in high-speed or RF applications, a lower and more stable Dk is often preferred to minimize signal delay and maintain impedance consistency across layers.

2. Dissipation Factor (Df) and Signal Loss

The dissipation factor (Df) indicates how much signal energy is lost as heat in the material. A lower Df means less signal loss, which is crucial for high-frequency designs.

- FR-4: Has a higher Df, typically around 0.02, leading to more signal loss at high frequencies (above 1 GHz). This makes it less suitable for applications requiring minimal signal attenuation.

- High-Frequency Materials: Feature a much lower Df, often below 0.003, reducing signal loss significantly. This property is vital for maintaining signal integrity in a complex 14-layer PCB design operating at high frequencies.

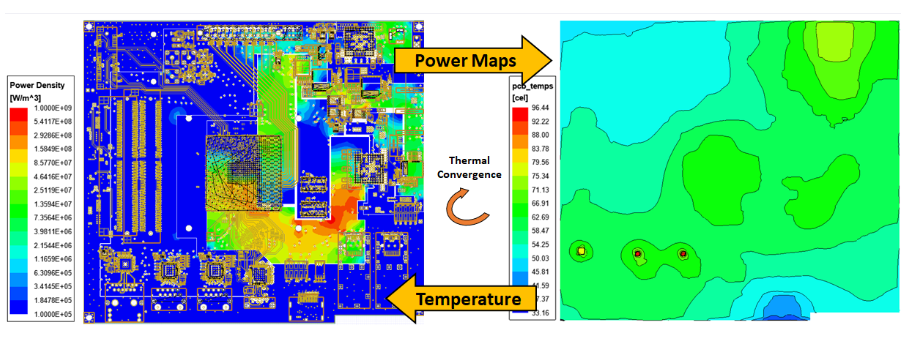

3. Thermal Stability and Management

With 14 layers, heat dissipation becomes a significant concern. Components on the board generate heat, and the material must withstand temperature changes without degrading.

- FR-4: Offers decent thermal stability with a glass transition temperature (Tg) of about 130-140°C for standard grades. However, it may struggle in extreme conditions or with high-power components due to its relatively high coefficient of thermal expansion (CTE).

- High-Frequency Materials: Typically have better thermal stability, with some formulations offering Tg values above 200°C and lower CTE. This makes them more reliable in environments with fluctuating temperatures or high heat output.

4. Cost and Manufacturability

Budget is always a factor in PCB design, especially for multilayer boards like a 14-layer PCB where material costs can add up quickly.

- FR-4: Is significantly more affordable and widely available. It’s also easier to process during manufacturing, requiring no special techniques, which keeps production costs low.

- High-Frequency Materials: Are more expensive due to their specialized composition. They may also require specific manufacturing processes, adding to the overall cost. However, the performance benefits often justify the price in critical applications.

FR-4 vs. High-Frequency Materials: A Direct Comparison for 14-Layer PCBs

Now that we’ve covered the key properties, let’s compare FR-4 and high-frequency materials head-to-head to help you decide which is best for your 14-layer PCB project.

| Property | FR-4 | High-Frequency Materials |

|---|---|---|

| Dielectric Constant (Dk) | ~4.5 (varies with frequency) | 2.2-10 (stable across frequencies) |

| Dissipation Factor (Df) | ~0.02 (higher signal loss) | <0.003 (minimal signal loss) |

| Thermal Stability (Tg) | 130-140°C (standard grades) | Up to 200°C or higher |

| Cost | Low | High |

| Applications | General-purpose, low-frequency | High-frequency, RF, microwave |

From this table, it’s clear that FR-4 is a versatile, budget-friendly option for many designs, while high-frequency materials excel in specialized, performance-critical applications.

When to Choose FR-4 for Your 14-Layer PCB

FR-4 is the go-to material for many engineers due to its balance of cost and performance. It’s an excellent choice for 14-layer PCBs in the following scenarios:

- General-Purpose Electronics: If your design operates at low to moderate frequencies (below 1 GHz), FR-4 provides adequate performance without unnecessary costs.

- Cost-Sensitive Projects: For applications where budget is a primary concern, FR-4 offers a reliable solution without breaking the bank.

- Standard Thermal Conditions: If your board won’t face extreme temperatures or high-power components, FR-4’s thermal properties are usually sufficient.

For example, a 14-layer PCB used in a consumer electronics device like a smart home controller can often use FR-4 without issues. Its signal requirements are typically within FR-4’s capabilities, and the cost savings are significant for mass production.

When to Choose High-Frequency Materials for Your 14-Layer PCB

High-frequency materials are the better choice for 14-layer PCBs in demanding applications. Consider them in these situations:

- High-Speed Digital Circuits: Designs operating at frequencies above 1 GHz, such as 5G equipment or high-speed data servers, benefit from the low signal loss and stable Dk of these materials.

- RF and Microwave Applications: For projects like radar systems or satellite communications, high-frequency materials are essential to maintain signal integrity across multiple layers.

- Harsh Environments: If your PCB will operate in extreme temperatures or with high-power components, the superior thermal stability of these materials ensures reliability.

For instance, a 14-layer PCB in a telecommunications base station handling high-frequency signals would perform better with specialized laminates. The reduced signal loss and stable impedance can make a noticeable difference in performance.

Hybrid Stackups: Combining Materials for Optimal Performance

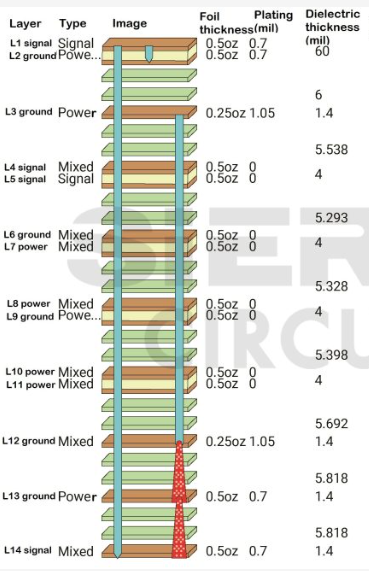

In some cases, you don’t have to choose just one material. A hybrid stackup combines FR-4 with high-frequency materials in a single 14-layer PCB to balance performance and cost. For example:

- Use high-frequency laminates for signal-critical layers (like top and bottom layers for RF traces).

- Use FR-4 for inner layers handling power or ground planes where high-frequency performance isn’t as critical.

This approach is common in complex designs where only specific layers need enhanced signal integrity. However, hybrid stackups can increase manufacturing complexity, so ensure your design and production processes can handle the mix of materials.

Practical Tips for Selecting 14-Layer PCB Materials

To wrap up, here are some actionable tips to guide your material selection process:

- Define Your Frequency Needs: Determine the operating frequency of your design. If it’s above 1 GHz, lean toward high-frequency materials for critical layers.

- Evaluate Thermal Requirements: Assess the thermal environment and power demands of your application. Choose materials with appropriate Tg and CTE values for reliability.

- Balance Cost and Performance: If budget is tight, consider hybrid stackups to use expensive materials only where necessary.

- Consult with Manufacturers: Work closely with your PCB fabrication partner to ensure the chosen materials are compatible with their processes and your design goals.

- Test and Validate: Before full production, prototype your 14-layer PCB with the selected materials to verify performance under real-world conditions.

Conclusion: Making the Right Choice for Your 14-Layer PCB

Selecting the right materials for a 14-layer PCB is a crucial step that impacts the success of your project. FR-4 offers a cost-effective, reliable option for many standard applications, while high-frequency materials provide unmatched performance for high-speed and RF designs. By understanding key properties like dielectric constant, dissipation factor, and thermal stability, you can make an informed decision that aligns with your technical and budgetary needs.

Whether you opt for FR-4, high-frequency laminates, or a hybrid approach, the goal is to ensure your 14-layer PCB performs optimally in its intended application. With careful consideration and the right partnership for fabrication, you can achieve a design that meets both performance and cost expectations.

ALLPCB

ALLPCB