1. Principle

Electromagnetic shielding operates by two mechanisms: reflection loss and absorption loss. Reflection loss occurs when the wave impedance of the shield differs from that of the surrounding space, causing incident electromagnetic waves to be reflected at the shield surface. Absorption loss refers to the portion of wave energy that enters the shield and is dissipated within it.

2. Wave Impedance

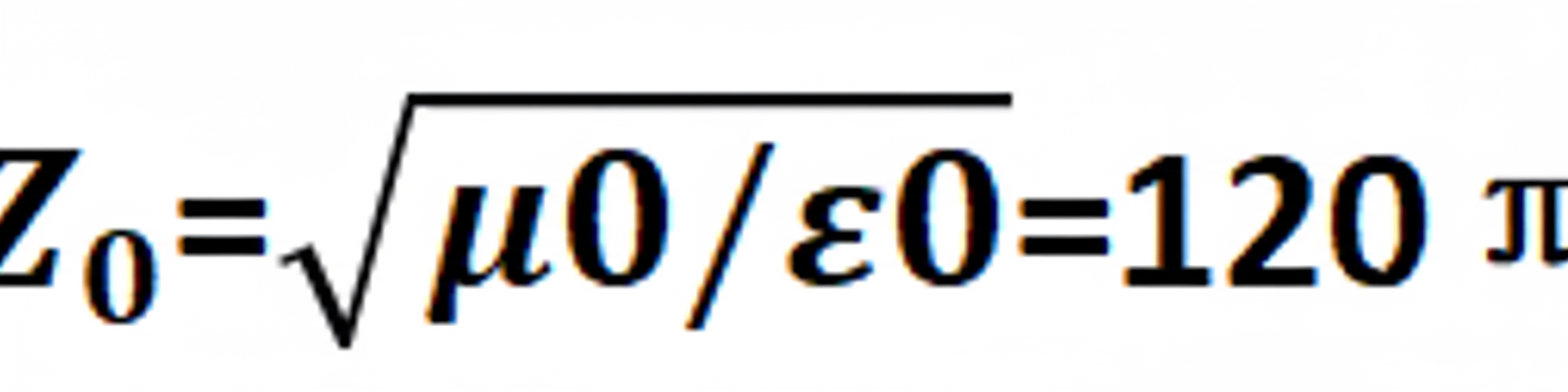

To understand reflection loss, it is necessary to know what wave impedance is. Wave impedance is the ratio of the electric field to the magnetic field for an electromagnetic wave propagating between two media, and it is the key parameter when discussing reflection loss. For a plane wave in free space, the wave impedance is:

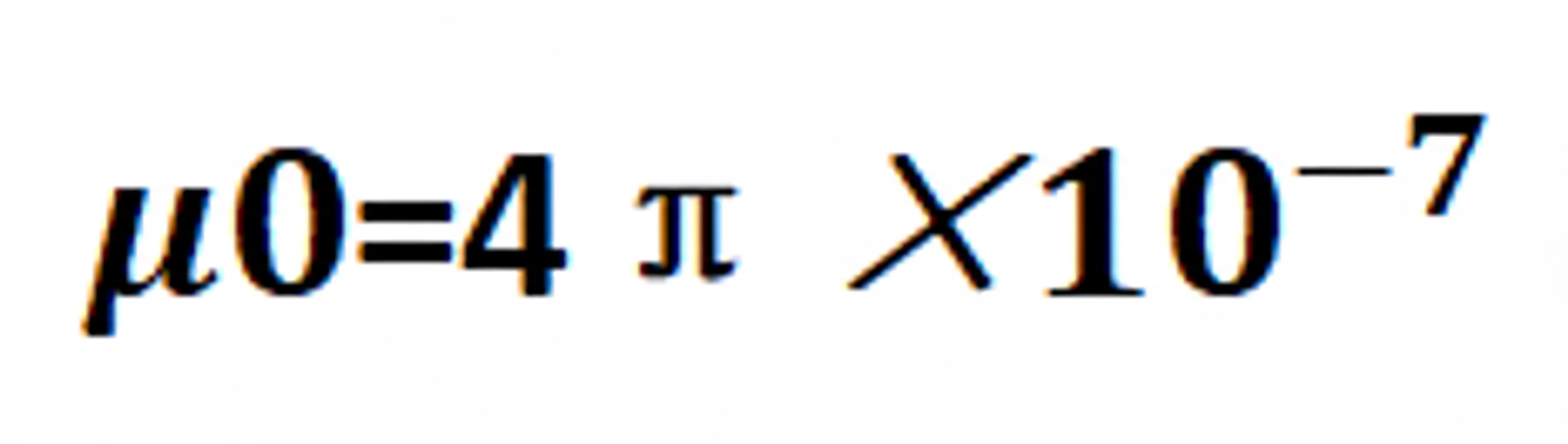

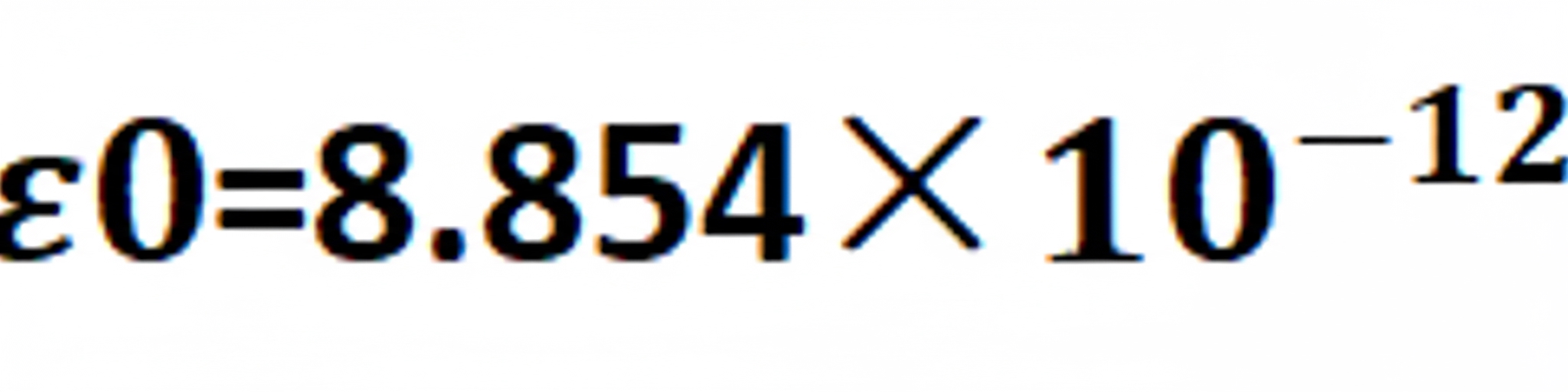

where:

These constants are important for far-field shielding analysis, because shielding is typically considered in free space and far-field electromagnetic waves are often approximated as plane waves. If the shield's wave impedance differs greatly from 377 Ω, significant reflection will occur and far-field shielding effectiveness can be substantially increased.

3. Reflection Loss and Absorption Loss

The wave impedance magnitude depends on the distance from the source that generates the electromagnetic wave. In the far field, the wave impedance becomes constant. In the near field, the wave impedance varies with distance and with the type of source. Sources are generally classified as either magnetic-field sources or electric-field sources.

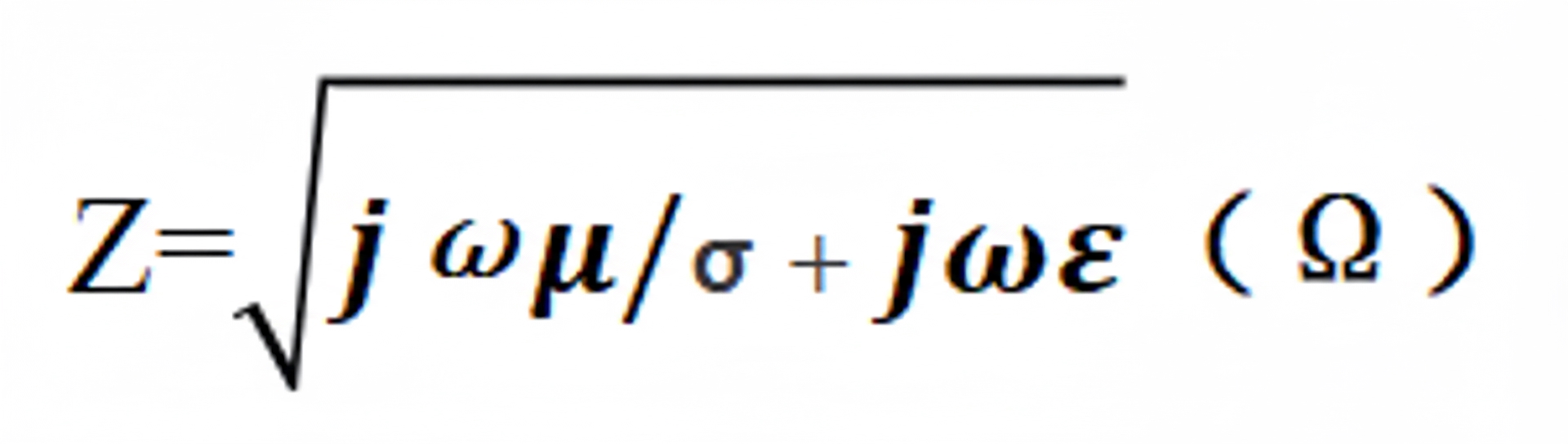

Near an electric-field source, the measured electric field is much larger than the magnetic field, so the wave impedance is large. Conversely, near a magnetic-field source, the measured wave impedance is small. Common shielding materials such as metals cannot rely on reflection loss to shield near-field magnetic sources effectively. The wave impedance of a metal is:

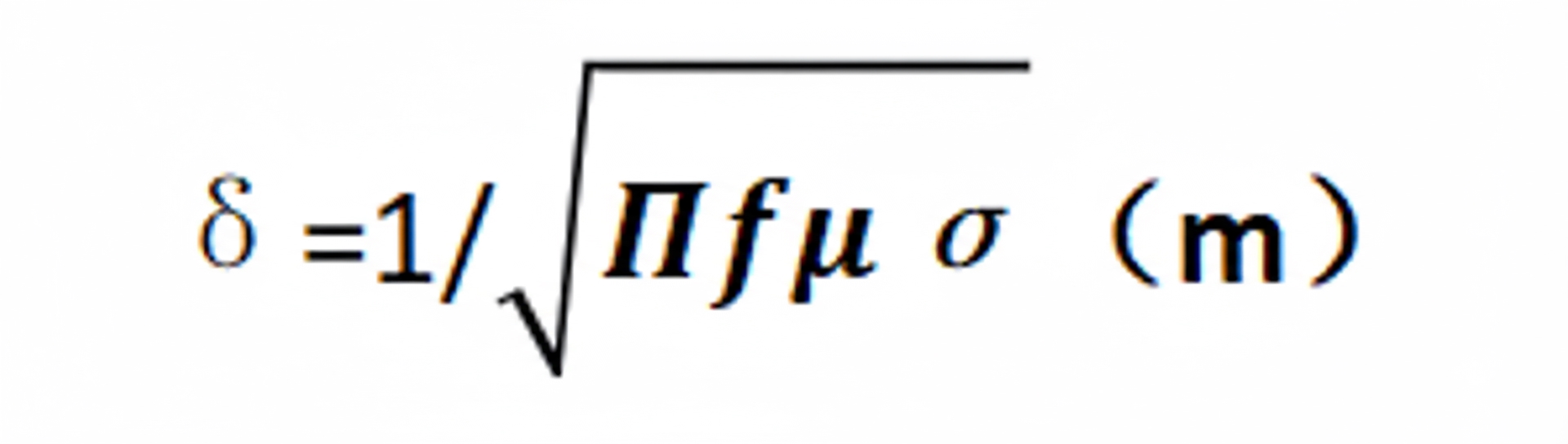

Since the electrical conductivity σ of metals is large, the wave impedance is very small and approaches the near-field impedance of a magnetic source, reducing reflection at the shield surface. When reflection is reduced, absorption loss becomes the dominant shielding mechanism. The magnitude of absorption loss depends on the shield thickness and the skin depth. Due to the skin effect, electromagnetic waves attenuate rapidly inside conductors, and the characteristic penetration distance is the skin depth, approximately given by:

where f is the wave frequency. Higher f or larger μ and σ reduce the skin depth. If the shield thickness exceeds the skin depth, absorption loss will significantly improve shielding effectiveness.

4. Case Study

When identifying noise sources inside a machine, it is common to find an existing shield cover yet still observe excessive radiation. One mitigation approach is to apply an additional layer of copper foil to the shield cover to improve shielding performance.

The image above shows copper foil added to the exterior of a shielded enclosure. The measured data are shown below.

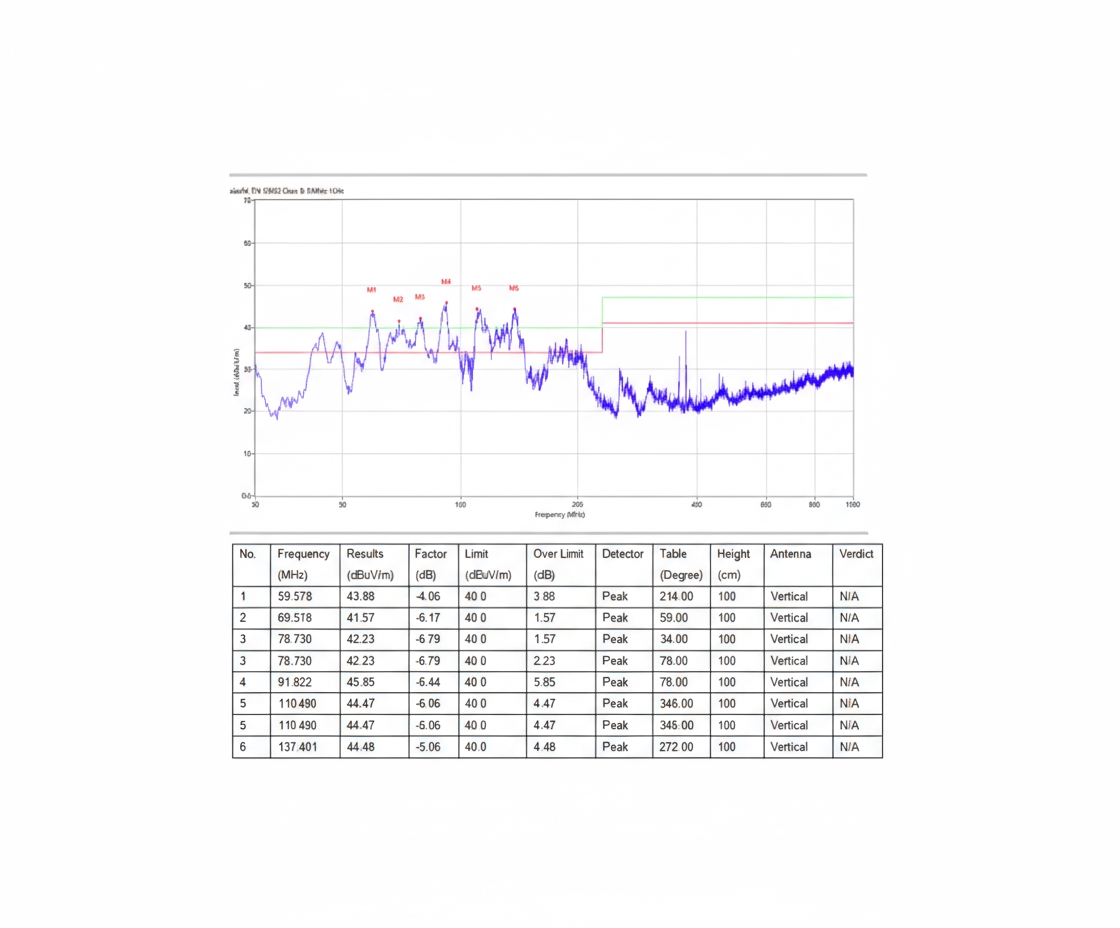

(data before reinforcement)

(data before reinforcement)

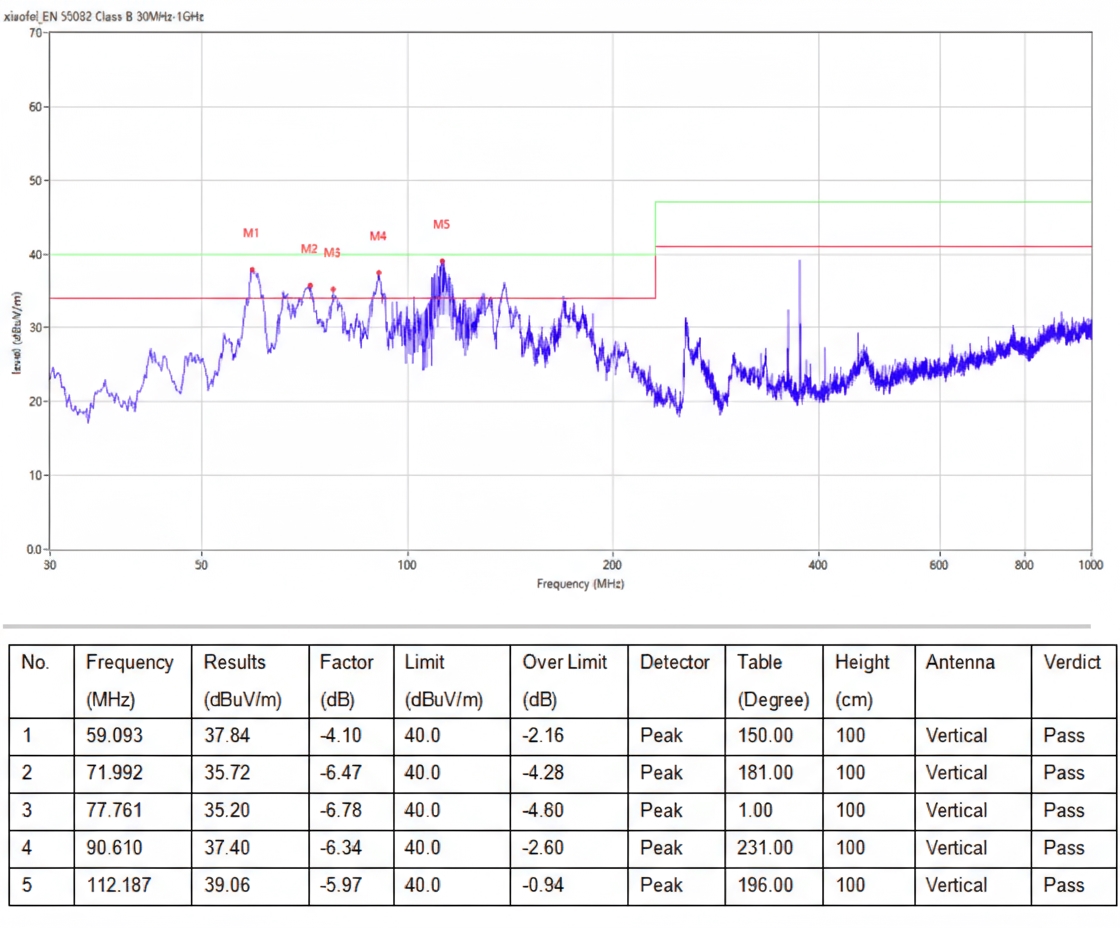

(data after reinforcement)

(data after reinforcement)

The measurements show that removing the shield and then adding improved shielding produces a clear effect, but the results may still be slightly short of passing certification. If the improved configuration reaches the target performance in testing, consider increasing the shield thickness or switching to other shielding materials for production to meet requirements.

ALLPCB

ALLPCB