When it comes to PCB cutting methods for depaneling, two popular techniques often come up: V-Score and Mouse Bites. If you're wondering which is best for your PCB, the answer depends on your design needs, production volume, and budget. V-Score is ideal for straight-line cuts and high-volume production due to its precision and clean separation, while Mouse Bites work well for irregular shapes and smaller batches with cost-effective simplicity. In this blog, we'll dive deep into both methods, comparing their benefits, drawbacks, and best use cases to help you make an informed decision for your next project.

What is Depaneling in PCB Manufacturing?

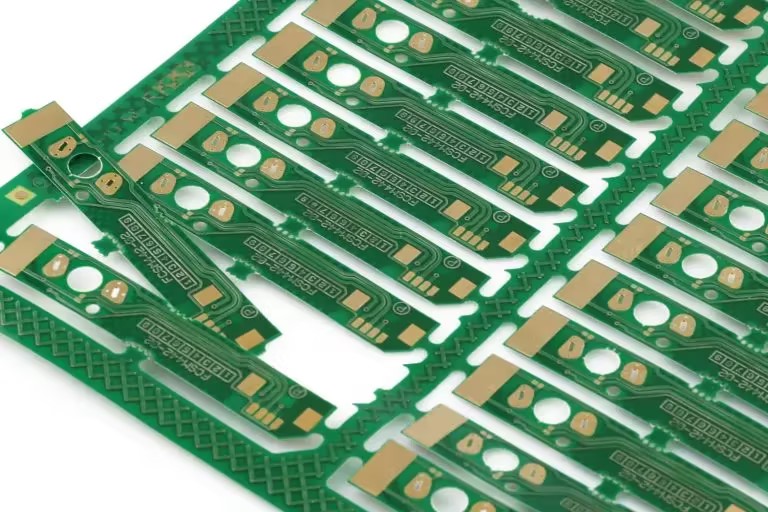

Depaneling is the process of separating individual printed circuit boards (PCBs) from a larger panel after manufacturing. PCBs are often produced in panels to optimize production efficiency, reduce costs, and streamline assembly. Once the manufacturing process is complete, these panels need to be divided into individual boards for use in electronic devices. The method chosen for depaneling can impact the board's structural integrity, production speed, and overall cost.

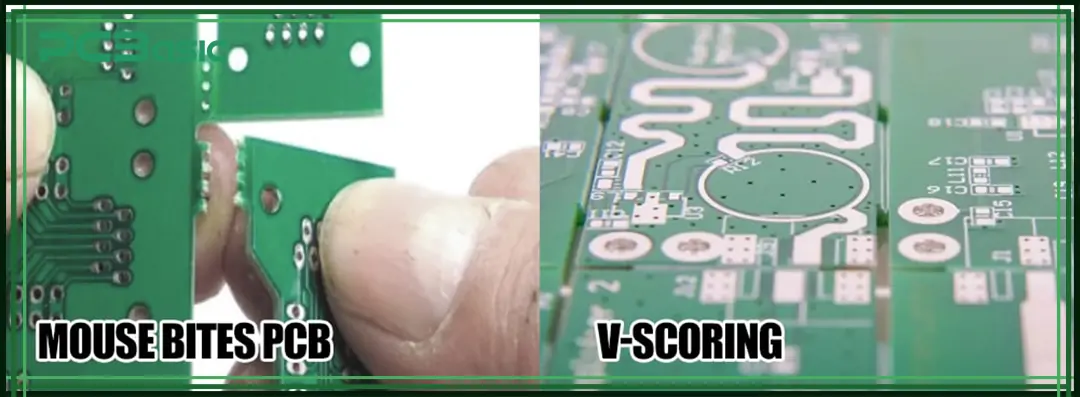

Two common depaneling techniques are V-Score (also called V-Cut or V-Groove) and Mouse Bites (also known as breakaway tabs or stamp holes). Both methods serve the same purpose but differ significantly in their application, design requirements, and results. Let’s explore each technique to understand how they work and when to use them.

Understanding V-Score in PCB Depaneling

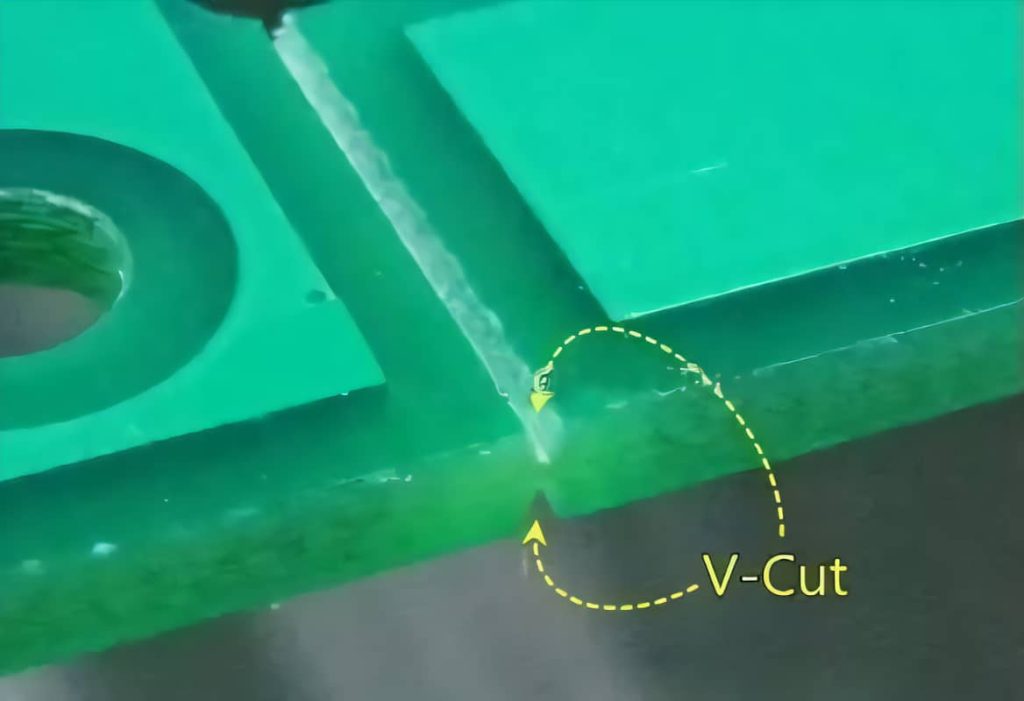

V-Score, or V-Cut, is a widely used depaneling method that involves creating V-shaped grooves on both sides of the PCB panel. These grooves weaken the material along a straight line, making it easy to snap the boards apart by hand or with minimal force. The cuts are typically made using a specialized scoring machine with angled blades, ensuring precision and consistency.

Advantages of V-Score

- Precision: V-Score provides clean, straight cuts with minimal stress on the board, reducing the risk of damage to components near the edges.

- Efficiency: This method is highly efficient for high-volume production as it allows quick and easy separation without additional tools.

- Cost-Effective for Large Runs: Once the scoring machine is set up, the process is fast and economical for large batches.

- Minimal Edge Roughness: The resulting edges are smoother compared to other methods, often requiring no further finishing.

Disadvantages of V-Score

- Limited to Straight Lines: V-Score can only be used for straight cuts, making it unsuitable for complex or irregular board shapes.

- Design Constraints: Components and traces must be placed away from the scoring line (typically at least 0.5 mm) to avoid damage during separation.

- Not Ideal for Small Runs: The setup cost for V-Scoring equipment can be high, making it less cost-effective for prototypes or small batches.

Best Use Cases for V-Score

V-Score is best suited for rectangular or square PCBs in high-volume production where straight cuts are needed. It’s commonly used in industries like consumer electronics, where uniformity and speed are critical. For example, if you're producing 10,000 identical boards for a smartphone component, V-Score can save time and ensure consistent results.

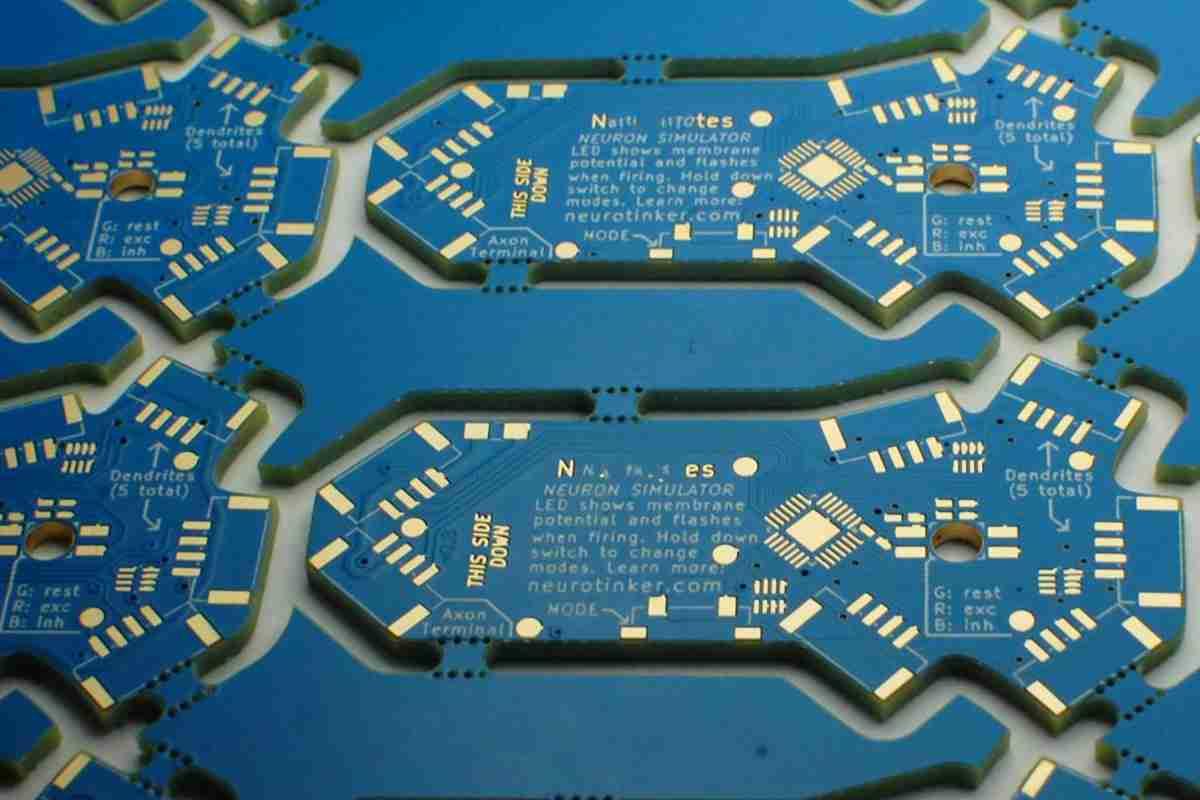

Understanding Mouse Bites in PCB Depaneling

Mouse Bites, also referred to as breakaway tabs or stamp holes, are small perforated holes drilled along the edges where individual PCBs connect in a panel. These holes create a weak point that allows the boards to be snapped apart by hand. The name "Mouse Bites" comes from the appearance of these small, closely spaced holes, resembling tiny bite marks.

Advantages of Mouse Bites

- Flexibility: Mouse Bites can be used for irregular or non-straight cuts, making them suitable for complex board shapes.

- Cost-Effective for Small Runs: This method doesn’t require specialized equipment beyond standard drilling tools, which makes it affordable for prototypes or low-volume production.

- Easy to Implement: Designing Mouse Bites into a panel is straightforward and can be done with basic PCB design software.

Disadvantages of Mouse Bites

- Rough Edges: Breaking the boards apart often leaves rough edges or small stubs, which may require additional sanding or finishing for aesthetic or functional reasons.

- Stress on Components: The snapping process can introduce mechanical stress, potentially damaging components close to the breakaway point if not designed carefully.

- Time-Consuming for Large Runs: Manually separating boards with Mouse Bites can be labor-intensive, making it less efficient for high-volume production.

Best Use Cases for Mouse Bites

Mouse Bites are ideal for prototypes, small-batch production, or designs with irregular shapes that cannot accommodate straight V-Score cuts. For instance, if you're testing a new PCB design with only 50 units and the board has a unique curved shape, Mouse Bites offer a practical and low-cost solution.

Comparing V-Score and Mouse Bites: Key Differences

To help you decide between V-Score and Mouse Bites for your PCB cutting method, let’s compare them across several critical factors:

| Factor | V-Score | Mouse Bites |

|---|---|---|

| Cut Type | Straight lines only | Irregular or curved lines possible |

| Edge Quality | Smooth, clean edges | Rough edges, may need finishing |

| Production Volume | Best for high-volume runs | Best for prototypes or low-volume runs |

| Cost | Higher setup cost, economical for large batches | Low setup cost, ideal for small batches |

| Stress on Board | Minimal stress during separation | Higher stress, risk to nearby components |

| Design Flexibility | Limited by straight-cut requirement | More flexible for unique shapes |

Design Considerations for V-Score and Mouse Bites

When choosing between these two PCB cutting methods, your design plays a crucial role. Here are some specific guidelines to keep in mind:

For V-Score

- Clearance Zone: Ensure a clearance of at least 0.5 mm between the V-Score line and any components or traces to prevent damage during separation.

- Board Thickness: V-Score works best on boards with a thickness of 0.6 mm to 1.6 mm. Thicker boards may require deeper grooves, increasing the risk of incomplete cuts.

- Panel Layout: Design your panel with straight separation lines to maximize the efficiency of V-Scoring.

For Mouse Bites

- Hole Spacing and Size: Use holes with a diameter of 0.8 mm to 1.2 mm, spaced 0.2 mm to 0.3 mm apart, to create a weak enough connection for easy breaking without excessive force.

- Component Placement: Keep sensitive components at least 2 mm away from the breakaway tabs to avoid stress-related damage.

- Edge Finishing: Plan for potential post-separation finishing if smooth edges are required for your application.

Which Depaneling Method Should You Choose?

Deciding between V-Score and Mouse Bites for your PCB cutting method boils down to a few key factors:

- Production Volume: For large-scale production (e.g., over 1,000 units), V-Score is often the better choice due to its speed and consistency. For prototypes or small runs (under 100 units), Mouse Bites are more economical.

- Board Shape: If your PCB design has straight edges, V-Score will provide cleaner results. For irregular or curved shapes, Mouse Bites offer the flexibility you need.

- Budget: If upfront costs are a concern, Mouse Bites require minimal investment in equipment. V-Score may involve higher initial costs but saves money in the long run for larger batches.

- Edge Quality Needs: If your application demands smooth edges for aesthetic or functional reasons (e.g., fitting into a tight enclosure), V-Score is superior. If edge quality isn’t critical, Mouse Bites can work with some post-processing.

Ultimately, there’s no one-size-fits-all solution. Many engineers even combine both methods in a single panel design, using V-Score for straight cuts and Mouse Bites for complex areas, to balance cost and efficiency.

Other PCB Cutting Methods to Consider

While V-Score and Mouse Bites are popular, they aren’t the only depaneling options available. Here are two other methods worth considering:

- Routing: This method uses a CNC machine to cut out individual boards with high precision, ideal for complex shapes or when V-Score and Mouse Bites aren’t suitable. However, it’s slower and more expensive.

- Laser Cutting: Laser depaneling offers unmatched precision and minimal stress on the board, perfect for delicate or high-density designs. Its main drawback is the high cost, making it less common for standard projects.

These alternatives may be worth exploring if neither V-Score nor Mouse Bites fully meets your needs, especially for specialized or high-value PCBs.

Tips for Optimizing Your PCB Depaneling Process

Regardless of the method you choose, optimizing your depaneling process can save time and reduce errors. Here are some practical tips:

- Work Closely with Your Manufacturer: Share your design files early and discuss depaneling options to ensure compatibility with their equipment and processes.

- Test Before Full Production: For new designs, produce a small batch to test the depaneling method and check for issues like component damage or edge quality.

- Balance Panel Size: Design your panel to maximize the number of boards while leaving enough space for separation features (grooves or holes) to avoid crowding.

- Document Specifications: Clearly specify your depaneling requirements in your design files, including groove depth for V-Score or hole spacing for Mouse Bites, to avoid miscommunication.

Conclusion: Making the Right Choice for Your PCB

Choosing between V-Score and Mouse Bites for your PCB depaneling needs comes down to understanding your project’s specific requirements. V-Score excels in high-volume production with straight cuts, offering precision and clean edges. Mouse Bites, on the other hand, provide flexibility for irregular shapes and cost savings for smaller runs, despite the potential for rougher edges. By evaluating factors like production volume, board design, budget, and edge quality needs, you can select the method—or combination of methods—that best suits your goals.

At ALLPCB, we’re committed to helping you navigate the complexities of PCB manufacturing, including choosing the right depaneling technique. Whether you’re working on a prototype or scaling up for mass production, our team is here to support you with tailored solutions and expert guidance. Optimize your PCB cutting methods today and ensure a seamless transition from design to finished product.

ALLPCB

ALLPCB