Introduction

Joint control is a core part of robotics, directly affecting motion accuracy, stability, and responsiveness. Traditional joint control solutions commonly use ARM- or DSP-based embedded systems, which have met many control requirements. However, as application scenarios grow more complex and performance demands increase, limitations of those architectures have become evident. The RISC-V open instruction set architecture offers new opportunities for robot joint control due to its openness, flexibility, and potential for high performance. This article examines examples of chips based on RISC-V cores and analyzes the advantages, key techniques, and future prospects of RISC-V-based embedded systems in robot joint control.

Why Joint Control Matters and Limits of Traditional Architectures

Importance of Joint Control

Joint control is fundamental to achieving precise robot motion. For industrial robots, service robots, and specialized robots, the precision and stability of joint control directly influence overall system performance. For example, in automotive manufacturing, industrial robots require precise position and torque control to ensure welding and assembly accuracy; in medical robots, joint precision affects surgical accuracy and safety; and in service robots, control stability determines adaptability and reliability in complex environments.

Limitations of Traditional Architectures

Traditional joint control solutions typically use ARM- or DSP-based embedded systems. While these designs balance performance and power consumption to some extent, they expose several limitations in complex scenarios:

- Closed architecture: ARM architectures and core implementations are often proprietary, limiting developers ability to customize and extend cores or instruction sets to meet specific needs.

- Power-performance trade-offs: Although ARM performs well for low-power applications, power consumption can increase significantly for high-performance tasks, making long-duration operation difficult.

- Real-time performance: Traditional embedded systems may experience response latency when running complex control algorithms, challenging the real-time requirements of multi-joint coordinated motion.

- Cost: Licensing and patent costs add economic burden to development and deployment, especially at scale.

Opportunities with RISC-V

RISC-V is an open instruction set architecture that has gained attention for its openness, modularity, and potential for high performance. Key features include:

- Open ISA: RISC-V is fully open, allowing developers to customize and extend the instruction set to optimize system design for specific applications.

- Modular design: Support for optional extensions, such as floating-point and vector operations, enables targeted optimization for application requirements.

- Potential for low power and high performance: The concise instruction set can enable designs that balance energy efficiency and computational capability.

- Growing ecosystem: With community and foundation support, development tools and resources for RISC-V are maturing, providing a richer ecosystem for robot joint control development.

RISC-V Core Features and Advantages

Openness and Flexibility

The open nature of the RISC-V ISA gives developers exceptional freedom to tailor instruction sets and microarchitecture to application needs. This flexibility is especially valuable for robot joint control, where requirements for control algorithms and real-time behavior vary across industrial, service, and medical robots.

Example: Trinamic Rocinate microcontrollers Trinamic used RISC-V openness to develop the Rocinate microcontroller series. These devices integrate a 32-bit RISC-V soft core with Trinamic motor-control intellectual property to provide an integrated motor-control solution. The Rocinate series supports servo, stepper, and brushless DC motors and integrates current-sensing and protection features to directly drive and precisely control various motors. In industrial robots, such microcontrollers can precisely regulate joint torque and position to ensure high assembly and welding accuracy; in service robots, they can enable smooth joint motion and improve stability.

Low Power and High Performance

The simplicity of the RISC-V ISA enables designs that balance power efficiency and performance. For joint control applications that demand real-time execution and energy efficiency, this balance is critical.

Example: Alibaba DAMO Academy Xuantie C930 The Xuantie C930 processor exemplifies high-performance RISC-V use in general-purpose compute and AI workloads. With a 512-bit vector engine and an 8 TOPS matrix engine, it can rapidly execute complex control algorithms such as PID, adaptive control, and fuzzy control, supporting real-time response and high-precision joint control.

Modularity and Scalability

RISC-V modularity allows adding instruction set extensions tailored to specific application needs, making it adaptable to complex control algorithms and varying real-time requirements.

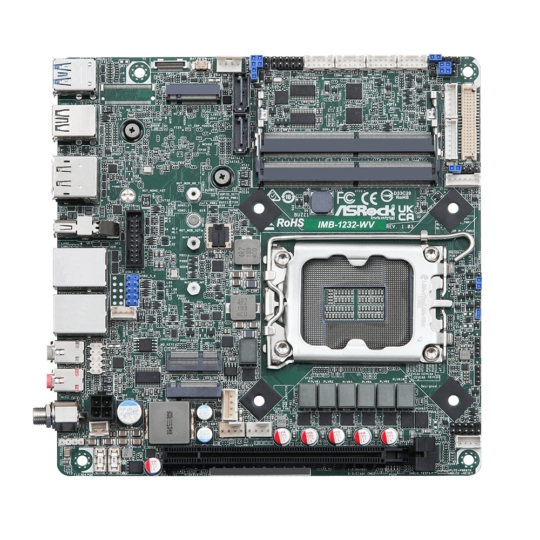

Example: Guoke Anxin AS32A601 MCU series The AS32A601 series provides rich peripheral interfaces and a modular design to meet various joint control needs. For example, six SPI channels supporting up to 30 MHz can quickly transfer joint control data; four CAN interfaces with CAN FD support multi-joint coordination in industrial robots. The integrated Ethernet MAC supports 10/100 Mbps modes, enabling efficient communication with supervisory systems.

Requirements and Challenges for Robot Joint Control

High-Precision Control

Joint control requires precise torque and position regulation. Traditional solutions may struggle to meet precision needs in high-accuracy scenarios.

Example: High-precision control in industrial robots In automotive manufacturing, robots need precise joint position and torque control for welding and assembly. RISC-V-based embedded systems with hardware FPUs and ECC protection mechanisms can provide high computational accuracy and data integrity, improving performance and reliability.

Real-time Performance

Joint control demands fast response to ensure smooth motion, particularly for coordinated multi-joint tasks. Traditional embedded platforms can experience latency when processing complex control algorithms.

Example: Real-time control in humanoid robots Humanoid robots require coordinated, low-latency control across many joints to maintain smooth and stable motion. RISC-V implementations with multi-stage pipelines and dynamic branch prediction can accelerate control algorithm execution to meet stringent real-time requirements.

Reliability

Robots often operate in complex or harsh environments, so joint control systems must be robust against interference and capable of fault detection and recovery.

Example: Reliability for outdoor robots Outdoor robots must handle varied terrain and weather. RISC-V-based embedded systems that incorporate end-to-end ECC protection and fault-detection mechanisms can improve reliability and tolerance to disturbances.

Low Power

Many robotic platforms require long operational times, making energy efficiency important. Traditional controllers can struggle to meet low-power demands for extended operation.

Example: Low-power control in UAVs Unmanned aerial vehicles have limited battery capacity and require long flight times while maintaining control of multiple joints. RISC-V-based systems with multiple power-management modes can dynamically adjust power consumption and extend endurance.

Applications of RISC-V Embedded Systems in Joint Control

System Architecture

RISC-V-based joint control systems typically adopt a layered architecture consisting of sensing, control, and actuation layers. This design enhances modularity and maintainability while reducing system complexity and cost.

Sensing layer The sensing layer acquires joint position, velocity, and torque data. Common sensors include encoders, current sensors, and torque sensors. For distributed sensor processing, microcontrollers such as the HPM5000 series provide high clock rates, high-precision ADCs, and interfaces like CAN and UART.

Control layer The control layer executes algorithms such as PID, adaptive, or fuzzy control. RISC-V cores with hardware FPUs and pipelined designs can efficiently run these algorithms to ensure real-time performance and accuracy.

Actuation layer The actuation layer drives joint motors and typically communicates with motor drivers via SPI or CAN. RISC-V-based microcontrollers, for example the Rocinate series, can directly control multiple motor types for precise joint actuation.

Example: Layered design in humanoid robots In humanoid robots, a layered RISC-V-based architecture improves modularity and maintainability. The sensing layer uses ADCs to collect joint position and torque; the control layer runs PID or advanced control algorithms; the actuation layer communicates with motor drivers via SPI or CAN to achieve precise joint actuation.

Key Technologies

Real-time performance RISC-V cores support multi-stage pipelines and dynamic branch prediction to accelerate control algorithm processing. High-performance MCUs may also integrate communication controllers such as USB, CAN FD, EtherCAT, Gigabit Ethernet controllers, and TSN switches. Technologies like EtherCAT can achieve microsecond-level latency and nanosecond-level jitter, suitable for joint-to-joint and dexterous-hand communication. TSN provides deterministic, high-bandwidth, and reliable data transmission for next-generation real-time networks.

High-precision control Hardware FPUs and ECC mechanisms ensure computational accuracy and data reliability.

Low power Support for multiple power-management modes enables dynamic power adjustment based on workload.

Safety and reliability End-to-end ECC and fault detection improve robustness under challenging conditions.

Example: Safety design in industrial robots In industrial robots, RISC-V-based embedded systems use end-to-end ECC and fault-detection to ensure reliable operation. Systems can monitor joint torque and position in real time and halt motion immediately if abnormal torque is detected to prevent accidents.

Implementation Example

Sensing layer Use ADCs on RISC-V chips to sample joint position and torque. High-performance MCUs with high-frequency cores and high-resolution ADCs are suitable for distributed sensor processing.

Control layer Run PID or advanced control algorithms on RISC-V cores. High-throughput vector and matrix engines can execute complex control tasks efficiently.

Actuation layer Communicate with motor drivers via SPI or CAN to achieve precise joint actuation.

Example: Precision in medical robots In medical robotics, joint control precision directly affects surgical accuracy and safety. RISC-V-based embedded systems can provide high-precision torque and position control and low-latency responsiveness, supporting delicate procedures and improving outcomes.

Future Research Directions and Application Prospects

Research Directions

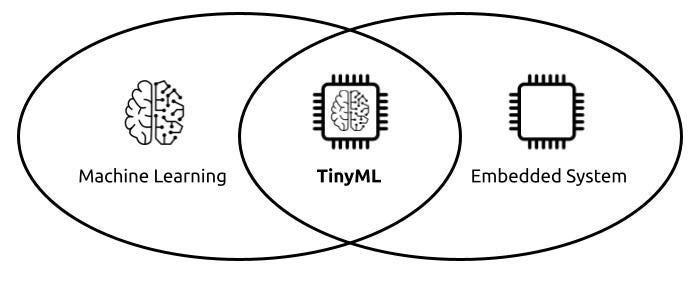

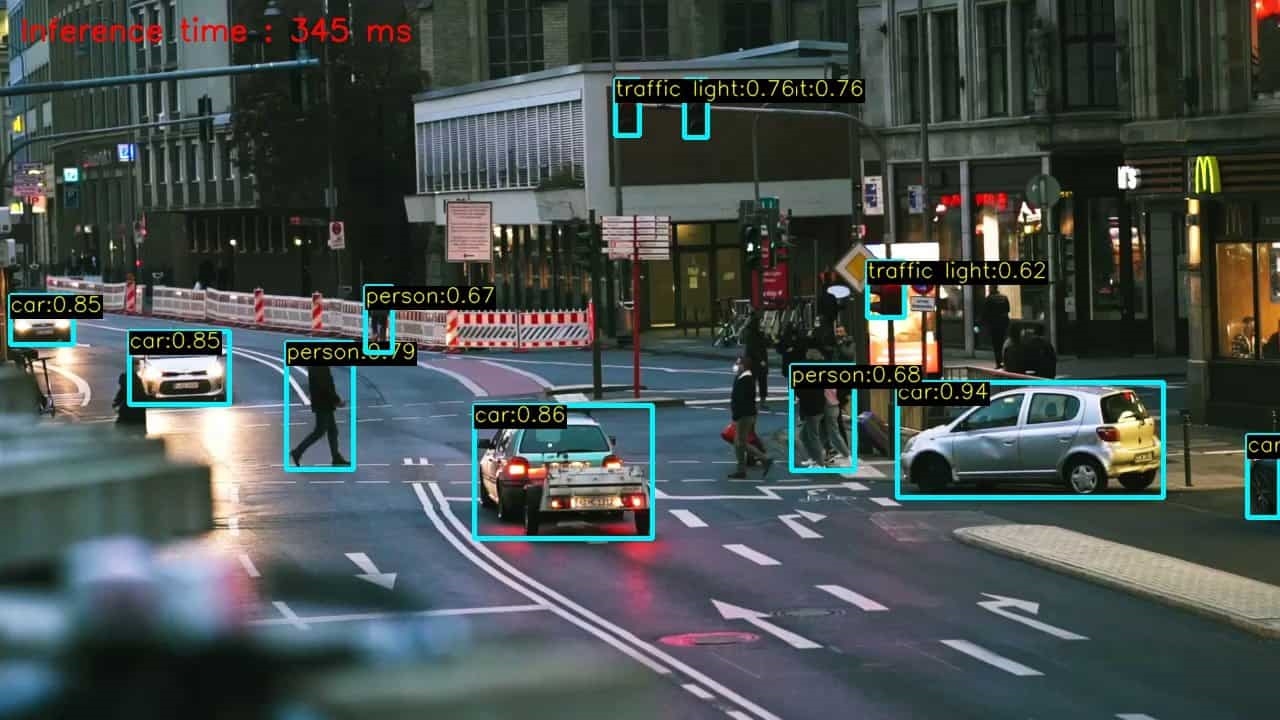

- Intelligent control algorithms: Integrate machine learning techniques to develop adaptive control algorithms that optimize parameters for varying loads and operating conditions.

- Multimodal perception: Fuse vision, tactile, and other sensors to enable more advanced joint control, such as vision-guided manipulation with tactile feedback.

- Distributed control: Use distributed architectures for coordinated multi-joint control to enhance scalability and flexibility, particularly in humanoid robots.

- Safety and reliability: Strengthen redundant designs and fault-detection to meet requirements in industrial and medical applications.

Application Prospects

- Industrial robots: RISC-V embedded systems can improve precision and efficiency in automotive and electronics manufacturing through high-precision joint control.

- Service robots: In home automation and healthcare, low-power and high-precision RISC-V solutions can extend operation time and improve reliability.

- Specialized robots: For military or rescue robots, RISC-V systems can enhance interference resilience and environmental adaptability.

- Medical robots: In minimally invasive surgery and rehabilitation, RISC-V-based control can improve precision and safety, supporting complex procedures and better patient outcomes.

Conclusion

RISC-V-based embedded systems offer notable advantages for robot joint control. Their openness, flexibility, and performance potential position them as a promising direction for future robotics. This article reviewed system architecture designs, key technologies, and implementation approaches through multiple examples. As the RISC-V ecosystem matures, its application in robotics is expected to expand further. Future work can focus on optimizing control algorithms, integrating AI and multimodal sensing, adopting distributed control architectures, and strengthening safety and reliability to address demands in industrial and medical domains.

ALLPCB

ALLPCB