In the world of electronics design, ensuring that a printed circuit board (PCB) performs reliably under varying conditions is critical. One of the biggest challenges is managing heat effectively. Poor thermal management can lead to component failure, reduced lifespan, and compromised performance. So, how do you optimize PCB thermal management for both manufacturability and reliability? The answer lies in strategic design techniques like using thermal vias, heat sinks, thoughtful component placement, and thorough thermal analysis.

In this comprehensive guide, we’ll dive deep into the essentials of PCB thermal management. From heat dissipation strategies to design tips that enhance manufacturability, we’ll cover actionable insights to help engineers create robust and efficient PCBs. Whether you're designing for high-power applications or compact devices, these tips will ensure your board stays cool and performs at its best.

Why PCB Thermal Management Matters

Heat is an inevitable byproduct of electronic components in operation. High temperatures can degrade components, cause thermal stress, and even lead to complete system failures. Effective thermal management ensures that heat is dissipated efficiently, maintaining the PCB and its components within safe operating temperatures, typically below 85°C for most standard components, though this can vary based on specific parts and applications.

Beyond reliability, thermal management also impacts manufacturability. Designs that account for heat dissipation are often easier to assemble and less prone to issues during production, such as warping or soldering defects caused by uneven heating. By prioritizing thermal design, you not only improve the performance of your PCB but also streamline the manufacturing process, reducing costs and time-to-market.

Key Strategies for Effective PCB Thermal Management

Let’s explore the core techniques that can help optimize heat dissipation while ensuring your PCB design is manufacturable and reliable. These strategies focus on practical solutions that engineers can implement during the design phase.

1. Leveraging Thermal Vias for Heat Dissipation

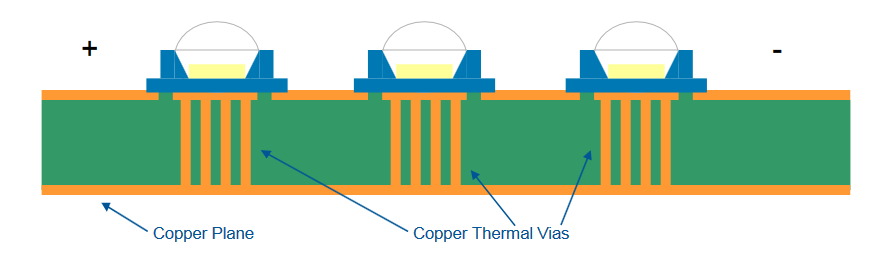

Thermal vias are small, plated-through holes that transfer heat from one layer of the PCB to another, often from a hot component on the surface to a heat-dissipating layer or ground plane. They act as conduits for heat, helping to spread it across a larger area or to a heat sink.

For instance, placing an array of thermal vias under a high-power component like a voltage regulator can reduce its operating temperature by 10-15°C, depending on the board’s thickness and material. A common practice is to use vias with a diameter of 0.3 mm to 0.5 mm, spaced 1.2 mm apart in a grid pattern, to maximize heat transfer without compromising structural integrity.

However, manufacturability must be considered. Too many vias can increase production costs and risk drilling defects. A balanced approach is to simulate heat flow during the design phase to determine the optimal number and placement of vias, ensuring they are effective without overcomplicating the board.

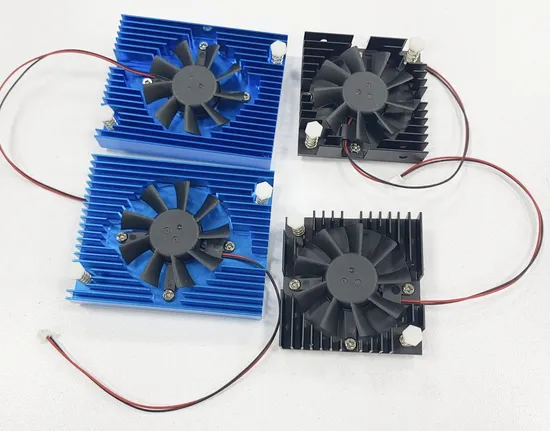

2. Incorporating Heat Sinks for High-Power Components

Heat sinks are passive cooling devices that absorb and dissipate heat away from critical components. They are especially useful for components like power transistors or microprocessors that generate significant heat, often exceeding 5W of power dissipation.

When integrating heat sinks, ensure they are properly sized and mounted. For example, a heat sink with a thermal resistance of 2°C/W can handle a 10W component while keeping temperature rise below 20°C above ambient. Placement is also key—position heat sinks where airflow is unobstructed, and use thermal interface materials (like thermal paste with a conductivity of 1-3 W/m·K) to enhance heat transfer between the component and the sink.

From a manufacturability standpoint, ensure that heat sink mounting holes or clips are accounted for in the PCB layout. This avoids assembly issues and ensures a secure fit during production. Additionally, consider the weight of the heat sink to prevent mechanical stress on the board during operation or shipping.

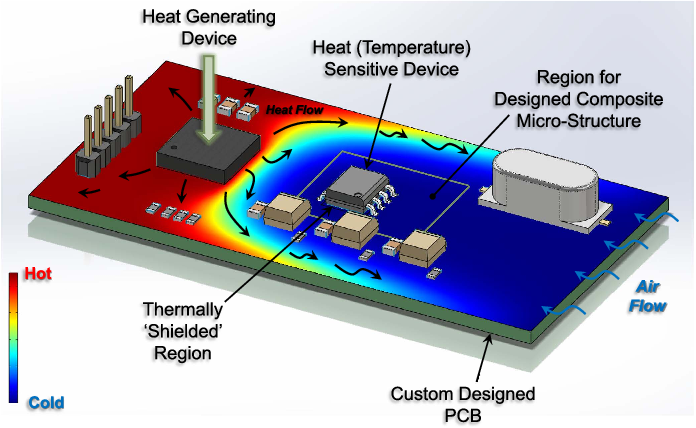

3. Optimizing Component Placement for Heat Distribution

The way components are placed on a PCB significantly affects heat distribution. Poor placement can create hot spots where heat accumulates, leading to thermal stress. A good rule of thumb is to space out heat-generating components to avoid concentrated heat zones. For example, placing two high-power ICs side by side can increase local temperatures by 20% compared to spacing them apart by at least 10 mm.

Additionally, position sensitive components, like capacitors or sensors, away from heat sources to prevent performance degradation. If possible, place high-power components near the edges of the board or areas with better airflow. This not only aids in heat dissipation but also simplifies the addition of cooling solutions during assembly.

For manufacturability, align component placement with standard assembly processes. Keep components accessible for soldering and inspection, and avoid placing large heat sinks or tall components in areas that might interfere with automated pick-and-place machines.

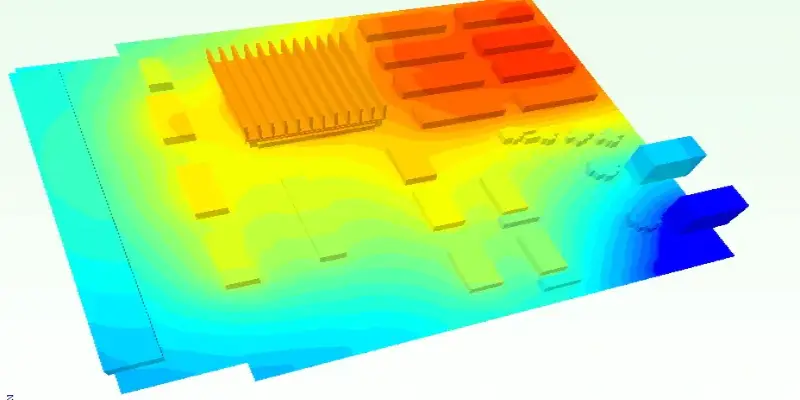

4. Conducting Thorough Thermal Analysis During Design

Thermal analysis is a critical step in PCB design to predict and address heat-related issues before manufacturing. Using simulation tools, engineers can model heat flow, identify hot spots, and test different cooling strategies. For example, a thermal simulation might reveal that a specific area of the board exceeds 100°C under load, prompting the addition of thermal vias or a heat sink.

Key parameters to analyze include the power dissipation of components (often provided in datasheets as 0.5W to 10W for typical ICs), ambient temperature (assume 25°C if unspecified), and the thermal conductivity of the PCB material (standard FR-4 has a conductivity of about 0.3 W/m·K). These simulations help ensure the design can handle worst-case scenarios, improving reliability.

From a manufacturability perspective, thermal analysis can also highlight potential issues like uneven heat distribution during reflow soldering, which could cause defects. Addressing these early in the design phase saves time and reduces costly revisions.

Material Selection for Enhanced Thermal Performance

The choice of PCB material plays a significant role in thermal management. Standard FR-4 material is cost-effective but has limited thermal conductivity. For high-power applications, consider using materials with better thermal properties, such as metal-core PCBs or high-Tg laminates. Metal-core PCBs, for instance, can have a thermal conductivity of 1-3 W/m·K, significantly better than FR-4, making them ideal for LED lighting or power electronics.

However, advanced materials often come with higher costs and may require specialized manufacturing processes. Balance performance needs with budget constraints, and consult with your PCB fabrication partner to ensure the chosen material aligns with production capabilities.

Balancing Thermal Management with Manufacturability

While optimizing for heat dissipation is crucial, it’s equally important to design with manufacturability in mind. Overly complex thermal solutions, such as excessive vias or custom heat sinks, can increase production costs and lead to assembly errors. Here are a few tips to strike the right balance:

- Standardize Components: Use commonly available heat sinks and thermal pads to avoid custom orders that delay production.

- Simplify Layouts: Minimize the number of layers and vias where possible, while still meeting thermal requirements, to reduce drilling and plating costs.

- Collaborate Early: Work closely with your manufacturing partner during the design phase to ensure thermal solutions are feasible within their process constraints.

By aligning thermal management strategies with manufacturing realities, you can achieve a design that’s both effective and cost-efficient.

Common Challenges in PCB Thermal Management

Even with the best strategies, thermal management comes with challenges. One common issue is underestimating heat generation, especially in compact designs where components are densely packed. This can lead to unexpected hot spots, with temperatures rising beyond safe limits (often above 105°C for many ICs).

Another challenge is balancing cost and performance. High-end cooling solutions like active fans or liquid cooling might be effective but are often impractical for most PCB applications due to cost and space constraints. Stick to passive solutions like vias and heat sinks unless the application demands otherwise.

Finally, environmental factors like ambient temperature or humidity can affect thermal performance. Designs for industrial or automotive applications, where temperatures can exceed 50°C, require extra consideration for heat dissipation compared to consumer electronics.

Best Practices for Long-Term Reliability

To ensure your PCB remains reliable over time, adopt these best practices in thermal management:

- Derate Components: Operate components below their maximum rated power (e.g., at 80% of capacity) to reduce heat stress and extend lifespan.

- Test Under Load: Perform real-world testing to validate thermal simulations, ensuring the design handles peak conditions without failure.

- Monitor Performance: For critical applications, integrate temperature sensors on the PCB to monitor heat levels during operation and trigger alerts if thresholds are exceeded.

These steps help prevent thermal-related failures, ensuring your PCB performs consistently even after years of use.

Conclusion: Building Better PCBs Through Thermal Optimization

Optimizing PCB thermal management is a cornerstone of designing reliable and manufacturable electronics. By leveraging techniques like thermal vias, heat sinks, strategic component placement, and thorough thermal analysis, you can effectively manage heat dissipation and prevent performance issues. At the same time, balancing these strategies with manufacturability ensures your design is practical and cost-effective to produce.

Whether you’re working on a high-power industrial system or a compact consumer device, prioritizing thermal management will enhance both the performance and longevity of your PCB. Start by integrating these tips into your design process, and collaborate with your fabrication partner to bring your vision to life with confidence.

ALLPCB

ALLPCB