Rigid-flex PCBs are a game-changer in modern electronics, combining the durability of rigid boards with the adaptability of flexible circuits. But how do you optimize the layer stack-up for rigid-flex PCB assembly to ensure signal integrity and meet manufacturing constraints? In this comprehensive guide, we’ll dive into the essentials of designing a rigid-flex PCB layer stack-up, focusing on impedance control, signal integrity, and practical manufacturing considerations. Whether you’re an engineer or a designer, you’ll find actionable insights to enhance your rigid-flex PCB projects.

What Is a Rigid-Flex PCB Layer Stack-Up?

A rigid-flex PCB layer stack-up refers to the arrangement of conductive and insulating layers in a circuit board that combines rigid and flexible sections. This hybrid design allows for compact, lightweight assemblies ideal for applications like wearables, medical devices, and aerospace systems. The stack-up defines how signals travel, how power is distributed, and how the board withstands mechanical stress. Optimizing this structure is critical for maintaining signal integrity in high-speed designs and ensuring manufacturability.

Why Layer Stack-Up Optimization Matters for Rigid-Flex PCBs

The layer stack-up directly impacts a rigid-flex PCB’s performance and reliability. A poorly designed stack-up can lead to signal loss, electromagnetic interference (EMI), and manufacturing defects. On the other hand, a well-optimized stack-up ensures consistent impedance, minimizes crosstalk, and aligns with manufacturing capabilities. For high-speed applications, where signals can reach frequencies above 1 GHz, even small mismatches in impedance (like deviations beyond ±10%) can degrade performance. Let’s explore the key aspects of optimization.

1. Ensuring Signal Integrity in Rigid-Flex PCB Designs

Signal integrity refers to the quality of an electrical signal as it travels through the PCB. In rigid-flex designs, maintaining signal integrity is challenging due to the transition between rigid and flexible sections, which can introduce impedance discontinuities. Here are key strategies to address this:

- Controlled Impedance: Impedance control in rigid-flex PCBs is vital for high-speed signals. For example, a common target impedance for differential pairs is 100 ohms ±10%. To achieve this, carefully select dielectric materials with consistent thickness (e.g., 0.002 inches for flex layers) and adjust trace widths accordingly.

- Layer Transitions: Minimize signal transitions between layers in the flex region to avoid reflections. If unavoidable, use vias with proper back-drilling to reduce stub effects.

- Ground Planes: Include continuous ground planes near signal layers to provide a return path and reduce EMI. In a 6-layer rigid-flex stack-up, place ground layers adjacent to high-speed signal layers for better shielding.

2. Impedance Control in Rigid-Flex PCB Layer Stack-Up

Impedance control is a cornerstone of high-speed design in rigid-flex PCBs. It ensures that signals travel without distortion, especially in applications like USB 3.0 or HDMI, where data rates exceed 5 Gbps. Here’s how to manage impedance:

- Material Selection: Flexible layers often use polyimide with a dielectric constant (Dk) around 3.2-3.5, while rigid sections might use FR-4 with a Dk of 4.2-4.5. Account for these differences when calculating trace impedance.

- Trace Geometry: Adjust trace width and spacing based on the stack-up. For a 50-ohm single-ended trace on a 0.0015-inch dielectric, a width of 0.006 inches might be needed. Use impedance calculators or simulation tools for precision.

- Flex Region Challenges: The thinner dielectric in flex areas can increase capacitance, altering impedance. Compensate by widening traces or adding coverlay material with known dielectric properties.

By focusing on impedance control in rigid-flex designs, you can prevent signal degradation and ensure reliable data transmission.

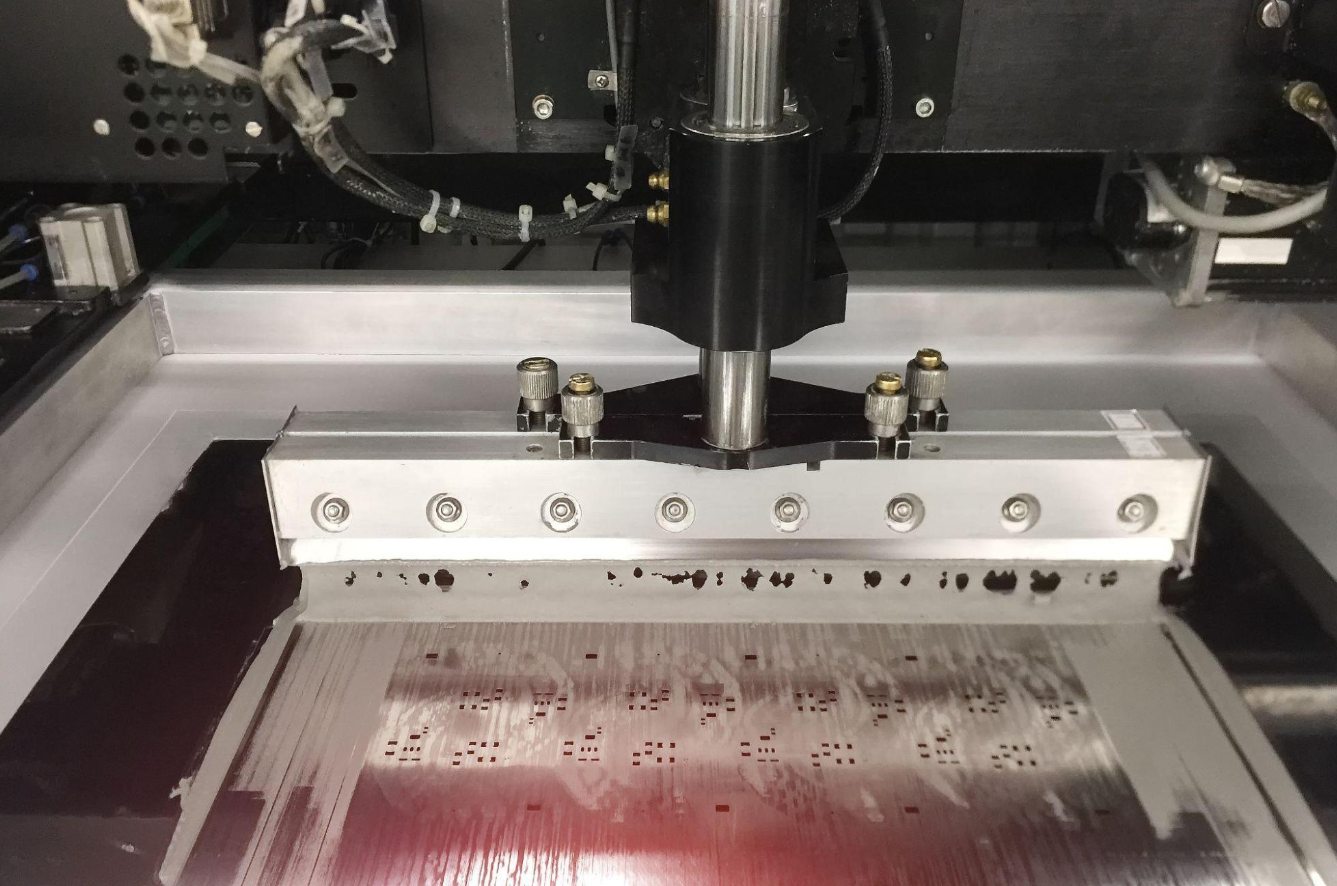

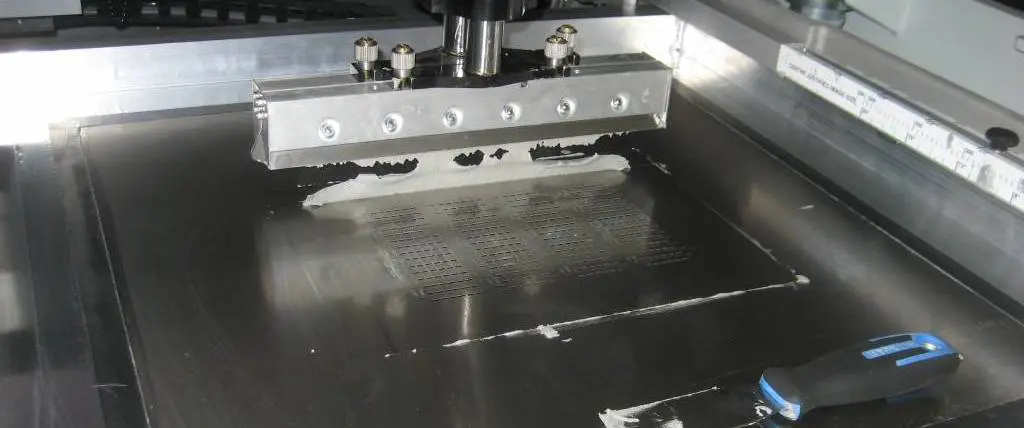

3. Addressing Manufacturing Constraints in Layer Stack-Up Design

Designing a rigid-flex PCB layer stack-up isn’t just about performance—it must also be manufacturable. Ignoring manufacturing constraints can lead to costly delays or defective boards. Consider these factors:

- Layer Count Limits: While a 12-layer rigid-flex PCB might be ideal for complex designs, many manufacturers have limits on flex layer counts (often 1-4 layers) due to process complexity. Verify capabilities before finalizing your stack-up.

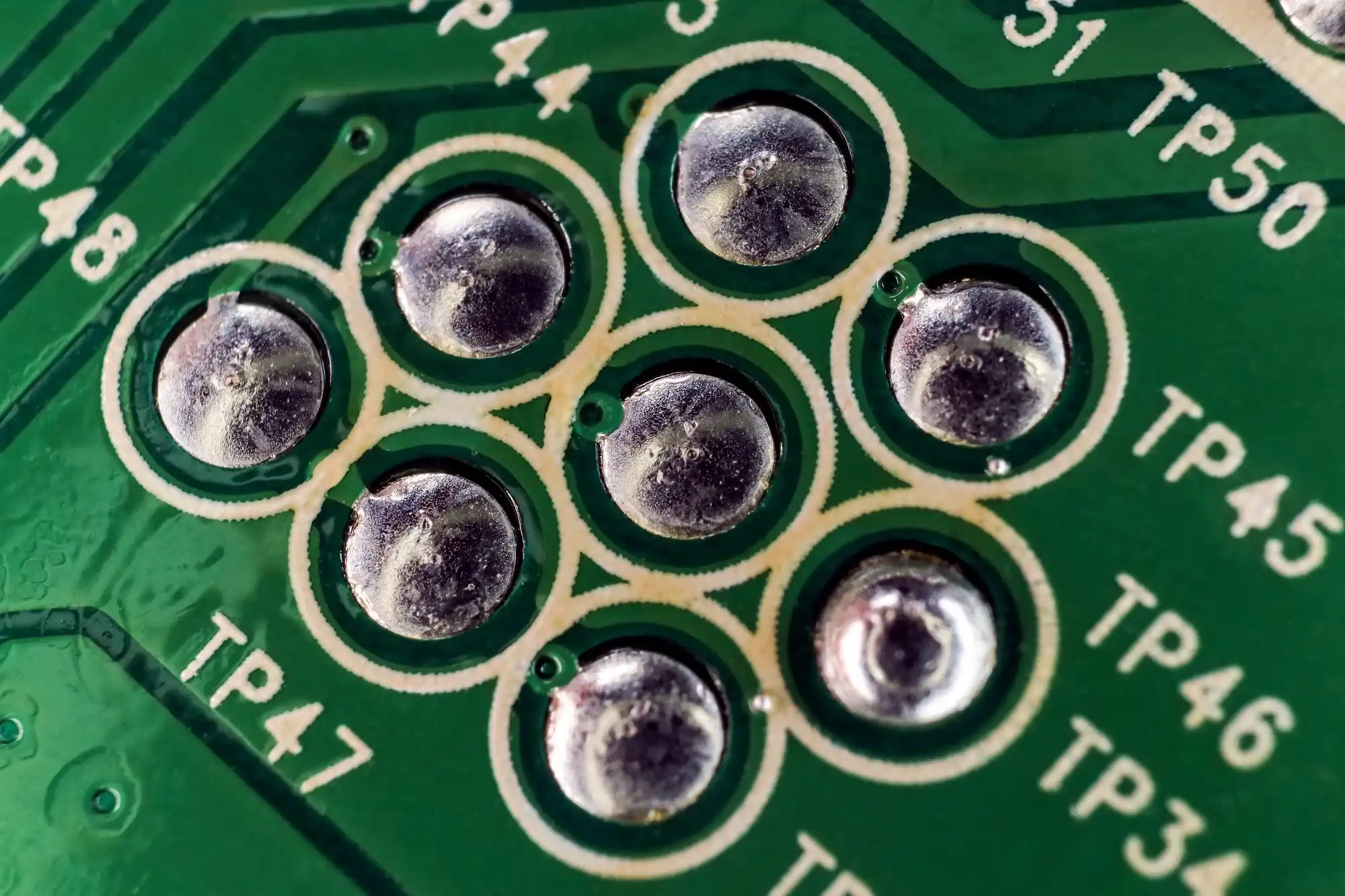

- Bend Radius: The flex section’s bend radius affects stack-up design. A minimum bend radius of 10 times the flex thickness (e.g., 0.030 inches for a 0.003-inch flex layer) prevents cracking. Avoid placing vias or thick copper in bend areas.

- Material Compatibility: Rigid and flex materials must bond reliably. Ensure adhesive layers (like acrylic or epoxy) are compatible with both sections and can withstand thermal cycles during assembly.

- Panelization: Design the stack-up with panelization in mind. Rigid-flex boards often require special fixturing during fabrication, so align your design with standard panel sizes to reduce waste and cost.

Rigid-Flex PCB Design Rules for Layer Stack-Up Optimization

To achieve a balanced rigid-flex PCB layer stack-up, follow these design rules tailored for signal integrity and manufacturability:

- Symmetrical Stack-Up: Maintain symmetry in the layer arrangement to prevent warping. For instance, in an 8-layer board, place equal numbers of rigid and flex layers on both sides of the center.

- Minimize Flex Layer Thickness: Keep flex layers thin (e.g., 0.001-0.003 inches) for flexibility, but ensure they’re thick enough to support copper traces without tearing.

- Avoid Overlapping Vias: Stagger vias in the rigid-to-flex transition zones to reduce stress concentration and prevent delamination.

- Signal Layer Placement: Position high-speed signal layers closer to the surface in rigid sections for easier impedance control, and shield them with ground planes in flex areas.

- Thermal Management: Include thermal vias or thicker copper (e.g., 2 oz instead of 1 oz) in rigid sections to dissipate heat, especially for power-heavy designs.

These rigid-flex PCB design rules help bridge the gap between theoretical performance and real-world application, ensuring your board functions as intended.

Common Challenges in Rigid-Flex PCB Layer Stack-Up Design

Even with careful planning, rigid-flex PCB designs can encounter issues. Here are common challenges and how to address them:

- Impedance Mismatch at Transitions: The shift from rigid to flex often causes impedance changes due to varying dielectric thicknesses. Use simulation tools to model these transitions and adjust trace widths to maintain consistency.

- Mechanical Stress: Repeated bending in flex areas can fatigue copper traces. Reinforce these areas with additional coverlay or design traces perpendicular to the bend direction.

- Cost Constraints: Complex stack-ups with many layers increase fabrication costs. Balance performance needs with budget by simplifying the design where possible, such as reducing layer count without sacrificing critical signals.

Step-by-Step Guide to Designing a Rigid-Flex PCB Layer Stack-Up

Follow these steps to create an optimized layer stack-up for your rigid-flex PCB assembly:

- Define Requirements: Identify the number of signals, power needs, and mechanical constraints. Determine if high-speed signals (above 500 MHz) require controlled impedance.

- Select Materials: Choose rigid (e.g., FR-4) and flex (e.g., polyimide) materials with matching thermal and electrical properties. Confirm dielectric constants and thicknesses.

- Plan Layer Arrangement: Sketch a stack-up with rigid and flex sections. For a 6-layer design, consider 4 rigid layers and 2 flex layers, with ground planes near signal layers.

- Calculate Impedance: Use tools to compute trace widths and spacing for target impedance values (e.g., 50 ohms for single-ended signals). Adjust based on material properties.

- Validate with Simulation: Run signal integrity simulations to check for reflections, crosstalk, and EMI. Refine the stack-up if issues arise.

- Consult Manufacturer: Share your design with the fabrication team to confirm it aligns with their capabilities, especially for flex layer count and bend radius.

- Finalize Design: Incorporate feedback, update documentation, and prepare for prototyping. Ensure all design rules are met before production.

This structured approach minimizes errors and ensures your rigid-flex PCB performs reliably in the field.

Conclusion: Balancing Performance and Manufacturability in Rigid-Flex PCB Stack-Up

Optimizing the layer stack-up for rigid-flex PCB assembly is a delicate balance of signal integrity, impedance control, and manufacturing constraints. By carefully designing the stack-up with controlled impedance, adhering to rigid-flex PCB design rules, and addressing manufacturing limitations, you can create boards that excel in high-speed applications while remaining cost-effective to produce. Whether you’re working on a compact wearable or a complex aerospace system, a well-thought-out stack-up is the foundation of success.

At ALLPCB, we’re committed to supporting your rigid-flex PCB projects with expertise and precision. From design consultation to assembly, our team ensures your boards meet the highest standards of performance and reliability. Start optimizing your designs today with these insights, and take your electronics to the next level.

ALLPCB

ALLPCB