In the world of printed circuit board (PCB) manufacturing and repair, two terms often come up: BGA rework and reflow soldering. If you're wondering about BGA rework vs reflow, the key difference lies in their purpose and process. BGA rework is a targeted repair or replacement process for Ball Grid Array (BGA) components on an existing PCB, while reflow soldering is a broader manufacturing technique used during SMT assembly to attach multiple surface-mount components to a board using a controlled heating process. In this blog, we’ll dive deep into these processes, exploring their differences, steps, and applications in PCB repair and assembly. Whether you're an engineer, technician, or hobbyist, this guide will help you understand these critical techniques.

What Are BGA Rework and Reflow Soldering?

Before we compare BGA rework vs reflow, let’s define each term to build a solid foundation. Both processes are essential in the field of electronics, especially when working with surface-mount technology (SMT assembly).

BGA Rework: BGA rework refers to the process of repairing or replacing a specific BGA component on a PCB. BGA components are integrated circuits with an array of solder balls on their underside, connecting them to the board. Rework is often necessary when a BGA fails, becomes outdated, or needs an upgrade. The process involves removing the faulty component, cleaning the area, and installing a new one with precision heating tools.

Reflow Soldering: Reflow soldering, on the other hand, is a manufacturing process used during the initial assembly of PCBs. It involves applying solder paste to the board, placing components (including BGAs and other surface-mount devices), and then heating the entire assembly in a reflow oven. The heat melts the solder paste, creating strong electrical and mechanical connections between components and the PCB.

In short, while reflow soldering is about creating connections during production, BGA rework focuses on fixing or modifying specific components after assembly.

Key Differences Between BGA Rework and Reflow Soldering

Understanding the differences between BGA rework vs reflow can help you choose the right approach for your project. Let’s break it down into several key areas:

1. Purpose and Application

- BGA Rework: The primary goal of BGA rework is repair or replacement. It’s used when a single BGA component fails due to issues like poor soldering, thermal stress, or manufacturing defects. It’s also common for upgrading components on an existing board or prototyping small batches. Rework is a localized process, focusing only on the specific component in question.

- Reflow Soldering: Reflow soldering is used during the initial manufacturing phase of SMT assembly. Its purpose is to attach multiple components to a PCB at once. This process is ideal for high-volume production, ensuring consistent and reliable connections across the entire board.

2. Equipment Used

- BGA Rework: BGA rework requires specialized equipment like rework stations with hot air tools or infrared heaters. These tools allow precise control over temperature to avoid damaging surrounding components. Rework stations often include features like automated alignment systems for accurate placement.

- Reflow Soldering: Reflow soldering uses a reflow oven, which heats the entire PCB assembly through a series of temperature zones. These ovens follow specific thermal profiles to ensure the solder paste melts and solidifies correctly without causing thermal shock to components.

3. Scale and Scope

- BGA Rework: This process is small-scale, targeting one or a few components. It’s a manual or semi-automated process, often performed by skilled technicians during PCB repair.

- Reflow Soldering: Reflow soldering operates on a larger scale, processing entire boards with hundreds or thousands of components at once. It’s an automated process suited for mass production.

4. Temperature and Control

- BGA Rework: Temperature control in BGA rework is highly localized. Technicians use tools to heat only the area around the BGA, often reaching temperatures between 200°C and 250°C for lead-free solder. Precision is critical to prevent damage to nearby components or the PCB itself.

- Reflow Soldering: Reflow soldering involves a controlled thermal profile with multiple stages (preheat, soak, reflow, and cooling). Peak temperatures in a reflow oven can reach up to 260°C for lead-free solder, applied uniformly across the board.

The BGA Rework Process: Step-by-Step

The BGA rework process is intricate and requires precision to avoid damaging the PCB or other components. Below is a detailed breakdown of the steps involved in repairing or replacing a BGA component:

Step 1: Preparation

Before starting, gather all necessary tools, including a BGA rework station, flux, solder balls (if reballing is needed), and cleaning supplies. Inspect the PCB to identify the faulty BGA and assess any visible damage. Protect surrounding components with heat-resistant tape or shields to prevent accidental damage during heating.

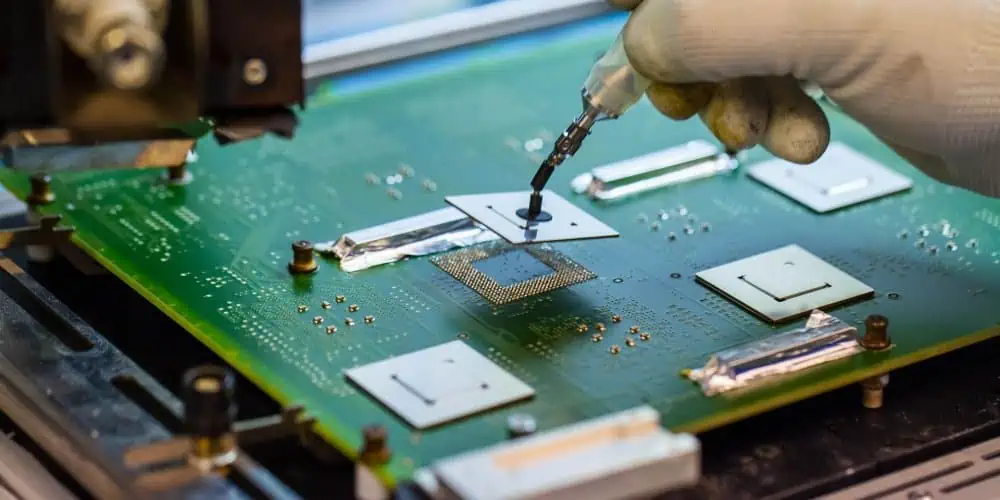

Step 2: Component Removal

Use the rework station to apply controlled heat to the BGA component. Hot air or infrared heating is typically used, with temperatures set according to the solder type (around 220°C-240°C for lead-free solder). Once the solder melts, carefully lift the BGA off the board using tweezers or a vacuum tool. Ensure the PCB pads are not damaged during removal.

Step 3: Cleaning the Site

After removing the BGA, clean the PCB pads to remove old solder and residue. Use a soldering iron with a desoldering braid or a specialized cleaning tool. Apply flux to the area to aid in cleaning and prepare the surface for the new component. If the BGA is being reused, it may need reballing—a process of attaching new solder balls to its underside.

Step 4: Placement of New BGA

Align the new or reballed BGA component with the PCB pads. Many rework stations have optical alignment systems to ensure precision, as even a slight misalignment can cause connection issues. Once aligned, secure the component in place temporarily.

Step 5: Soldering the BGA

Heat the BGA area again using the rework station to melt the solder balls and form connections with the PCB pads. Follow a thermal profile similar to reflow soldering but localized to the component. After heating, allow the area to cool gradually to avoid thermal stress.

Step 6: Inspection and Testing

Inspect the reworked BGA using X-ray imaging or visual inspection under a microscope to check for proper solder joint formation. Test the PCB to ensure the component functions correctly and there are no shorts or open connections.

Reflow Soldering Process: Step-by-Step

Reflow soldering is a cornerstone of modern SMT assembly. It’s designed for efficiency and consistency during PCB manufacturing. Here’s how the process works:

Step 1: Solder Paste Application

Solder paste—a mixture of tiny solder particles and flux—is applied to the PCB using a stencil. The stencil ensures paste is placed only on the pads where components will be mounted. This step is critical for creating reliable connections.

Step 2: Component Placement

Automated pick-and-place machines position components onto the PCB, aligning them with the solder paste on the pads. This includes BGA components, resistors, capacitors, and more. Precision is key to avoid misalignment.

Step 3: Heating in Reflow Oven

The PCB passes through a reflow oven with multiple temperature zones. The thermal profile typically includes:

- Preheat Zone: Gradually raises the temperature to 150°C-180°C to activate the flux and prevent thermal shock.

- Soak Zone: Maintains a temperature of 180°C-200°C to ensure even heating across the board.

- Reflow Zone: Peaks at 240°C-260°C (for lead-free solder) to melt the solder paste and form joints.

- Cooling Zone: Slowly cools the board to solidify the solder without causing stress.

Step 4: Inspection

After cooling, the PCB undergoes inspection using automated optical inspection (AOI) or X-ray systems to check for soldering defects like bridging, voids, or misalignment. Any issues may require rework.

Challenges in BGA Rework and Reflow Soldering

Both processes come with unique challenges that engineers must address to ensure quality results in PCB repair and manufacturing.

Challenges in BGA Rework

- Thermal Damage: Excessive heat can damage nearby components or the PCB substrate. Using precise temperature control and heat shields is essential.

- Alignment Issues: Misaligning a BGA during placement can lead to poor connections. Advanced rework stations with optical systems help mitigate this.

- Solder Joint Reliability: Ensuring uniform solder joints during rework is challenging, especially with lead-free solder, which requires higher temperatures (up to 260°C).

Challenges in Reflow Soldering

- Thermal Profile Accuracy: An incorrect thermal profile can cause incomplete soldering or component damage. For instance, a peak temperature below 240°C may not fully melt lead-free solder.

- Solder Voids: Air pockets in solder joints, especially under BGAs, can weaken connections. X-ray inspection helps detect these issues.

- Component Warpage: Large components or panels may warp under heat, leading to uneven soldering. Advanced ovens with warpage suppression features can help.

When to Use BGA Rework vs. Reflow Soldering

Choosing between BGA rework vs reflow depends on your specific needs:

- Opt for BGA Rework if you’re dealing with a single faulty or outdated component on an existing PCB. It’s ideal for PCB repair, prototyping, or small-scale upgrades.

- Choose Reflow Soldering for initial manufacturing or assembling new PCBs in bulk. It’s the go-to method for SMT assembly in high-volume production environments.

Conclusion

Understanding the differences between BGA rework vs reflow is crucial for anyone involved in electronics manufacturing or repair. While BGA rework focuses on precision repairs and replacements of specific components, reflow soldering is a broad, automated process for assembling entire PCBs during production. Both techniques play vital roles in SMT assembly and PCB repair, and knowing when and how to use them can save time, reduce costs, and ensure reliable results. By mastering the BGA rework process and reflow soldering techniques, you can tackle a wide range of challenges in the ever-evolving world of electronics.

ALLPCB

ALLPCB