Overview

Audi has invested substantial effort in developing electric drive systems. This article continues the discussion on Audi's choice of motors.

Vehicle output and efficiency figures

- Q6 e-tron system output: 285 kW (kWh/100 km combined consumption: 19.4–17.0 WLTP)

- SQ6 e-tron system output: up to 380 kW (kWh/100 km combined consumption: 18.4–17.5 WLTP)

The vehicles use a front induction motor paired with a rear permanent magnet synchronous motor, together with an adapted regenerative braking system. Several different configurations are supported.

1. Powertrain configuration

The Q6 e-tron family adopts a front induction motor and a rear permanent magnet synchronous motor combination to provide strong power output and balanced range performance.

The front induction motor is used as an auxiliary power source, contributing during acceleration, off-road and dynamic driving modes, while the rear permanent magnet synchronous motor drives the vehicle for most operating conditions. Permanent magnet synchronous motors offer steady efficiency and higher energy utilization, whereas induction motors provide high peak torque and good continuous power characteristics.

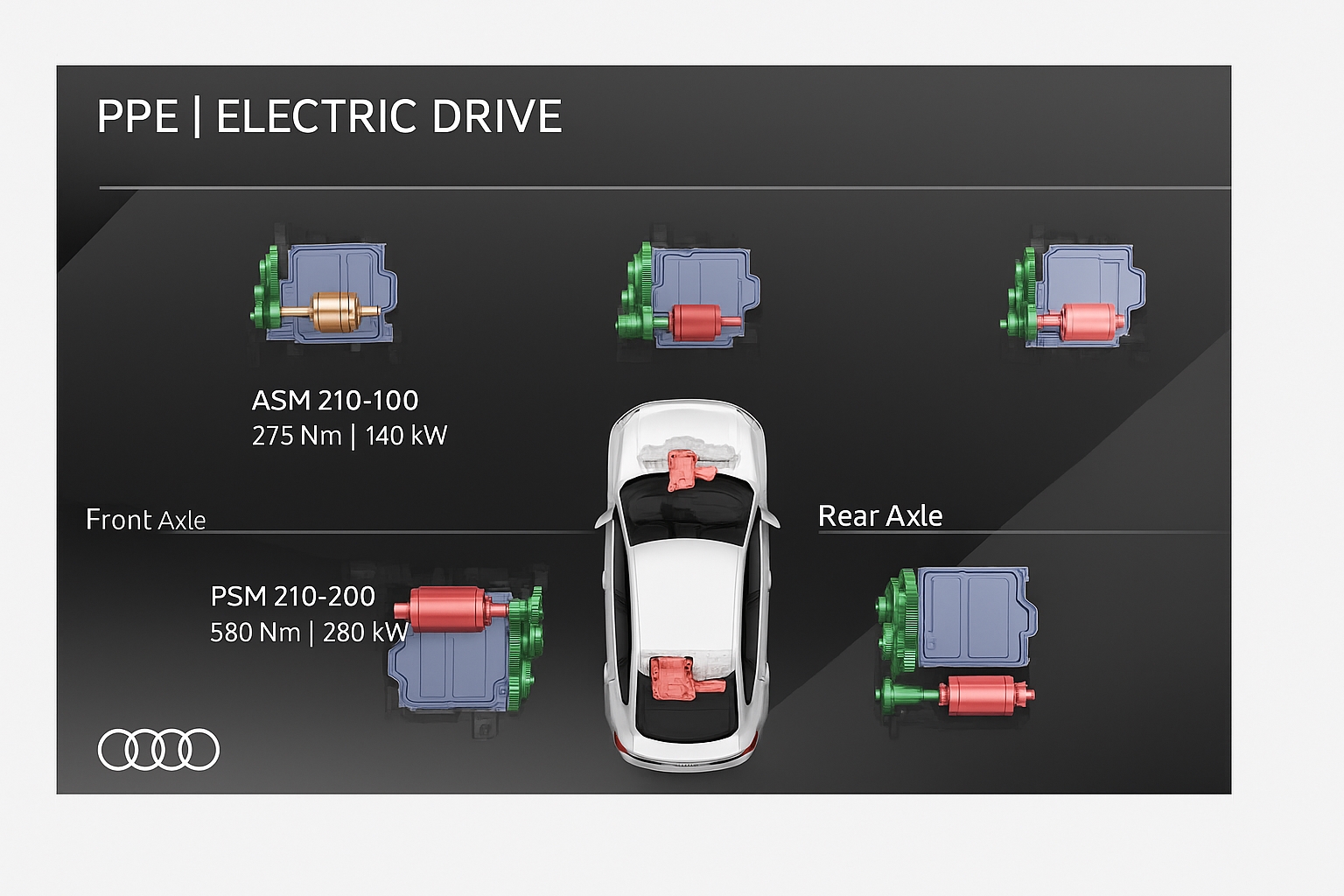

On the PPE platform, this front-rear motor pairing is more flexible. Different variants of the front induction motor and the rear motor can be used to offer different power and performance levels across models.

Motor examples

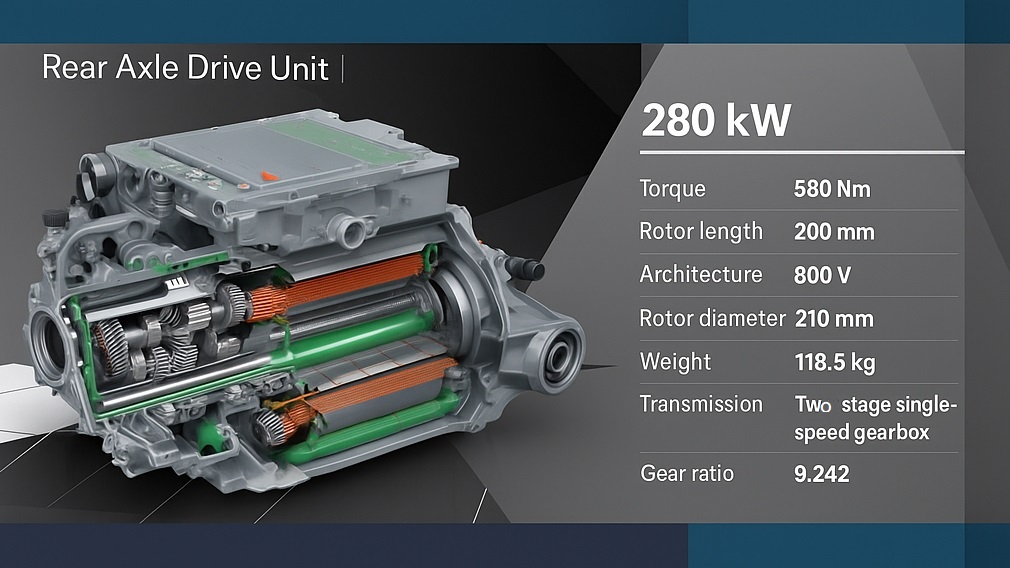

The PSM permanent magnet synchronous motor has a peak power of up to 280 kW, is paired with an 800 V power electronics system, and weighs 118.5 kg.

The ASM induction motor provides up to 140 kW peak power, also paired with an 800 V power electronics system, and weighs 87.5 kg.

These motors share identical internal dimensions, allowing internal components to be produced from the same tooling for multiple configurations, which speeds up manufacturing and reduces cost.

2. Regenerative braking system

In addition to motor optimization, Audi upgraded the regenerative braking system. The regenerative system supports up to 220 kW of recovery power and can perform independent regenerative control on the front and rear axles. Under different driving conditions, energy recovery is adaptively distributed to maximize energy utilization and maintain driving comfort.

For example, during normal highway driving the rear permanent magnet synchronous motor handles most of the regeneration, while the system adaptively engages the front axle when more regenerative braking is required. This front-rear adaptive regenerative distribution aims to smooth deceleration, improve safety, and provide more predictable coasting distances, which can reduce motion sickness for passengers.

Summary

The Q6 e-tron series' latest technology specifications illustrate recent progress in electric vehicle drive systems. By combining front induction motors with rear permanent magnet synchronous motors and using an adaptive front-rear regenerative braking system, the architecture targets improved energy efficiency, reduced consumption, and enhanced overall system performance.

Compared with the first generation, energy consumption is reduced by 30% and system performance is increased by 33%. The platform also supports more software-defined vehicle capabilities and reduces vehicle weight.

ALLPCB

ALLPCB