Definition

Steer-by-wire removes the physical mechanical connection between the steering wheel and the wheels, replacing it with electrical signals to command wheel steering. The system can reproduce the advantages of traditional mechanical steering while enabling control over steering-angle transfer characteristics that are difficult to achieve with mechanical linkages.

Background and industry status

The technology itself is not entirely new. Several OEMs, including Toyota, Volkswagen, Great Wall, BYD, and NIO, as well as tier-1 suppliers Bosch, Continental, and ZF, have long been developing steer-by-wire systems. To date, the most notable large-scale production deployment is Tesla's Cybertruck.

The performance of the Cybertruck in production will influence market adoption. Steer-by-wire is also a core technology for the skateboard chassis platform, so its mass-production behavior is of broad technical interest.

Safety and redundancy considerations

Replacing mechanical drive components with electrical actuation can reduce vehicle weight and simplify packaging, which has implications for cost and range. However, because control is transmitted by electrical signals, any failure can have severe consequences. For this reason, steer-by-wire implementations borrow redundancy practices from aviation, using multiple backup systems to ensure continued steering control.

Current automotive deployments are more common on rear-wheel steer systems; front-wheel steer-by-wire applications remain limited. This caution reflects the need for extremely high reliability, because electrical faults can arise from several sources such as battery failure, loss of signal, or communication delays.

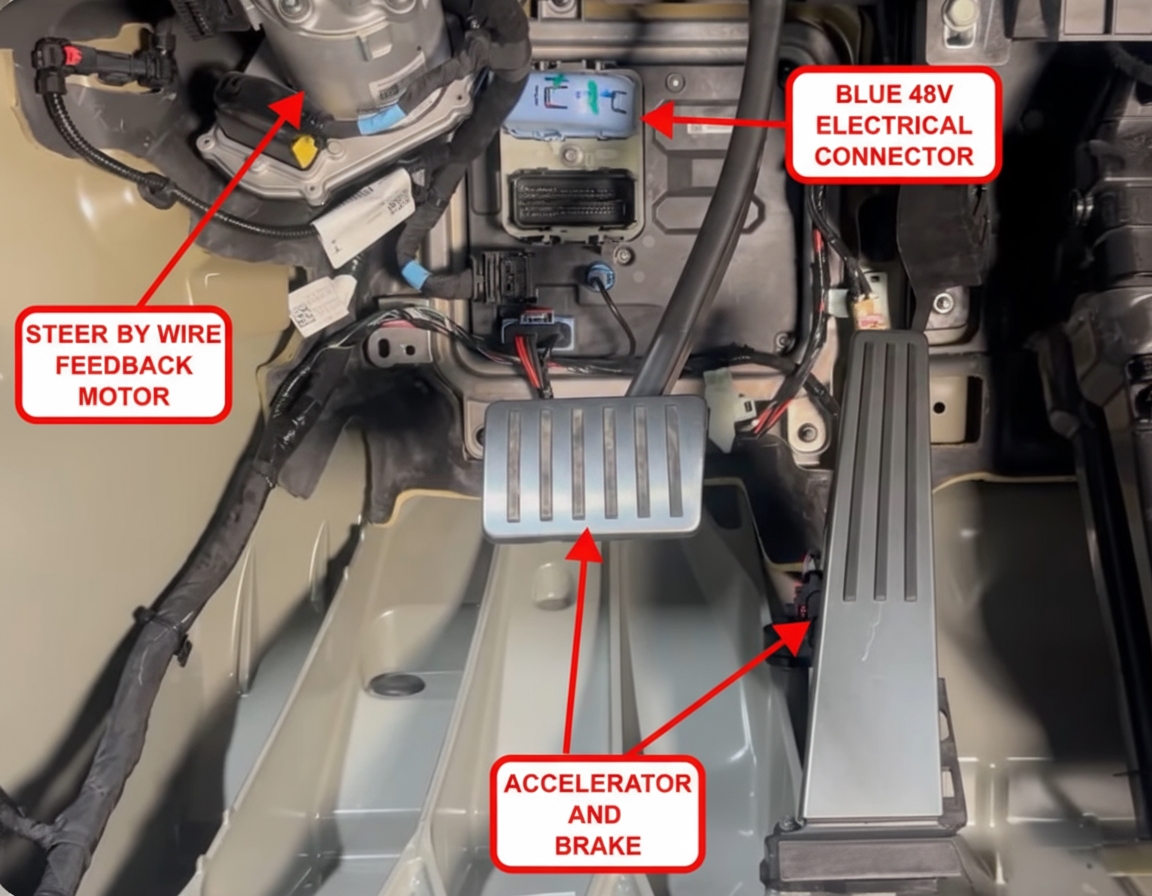

In the Cybertruck, to mitigate the risk of sudden battery loss, the system supplies the steering motors from a 48 V battery while also connecting to the high-voltage bus. Two additional backup batteries are included to provide further redundancy and prevent a total power loss.

Actuation and driver feedback

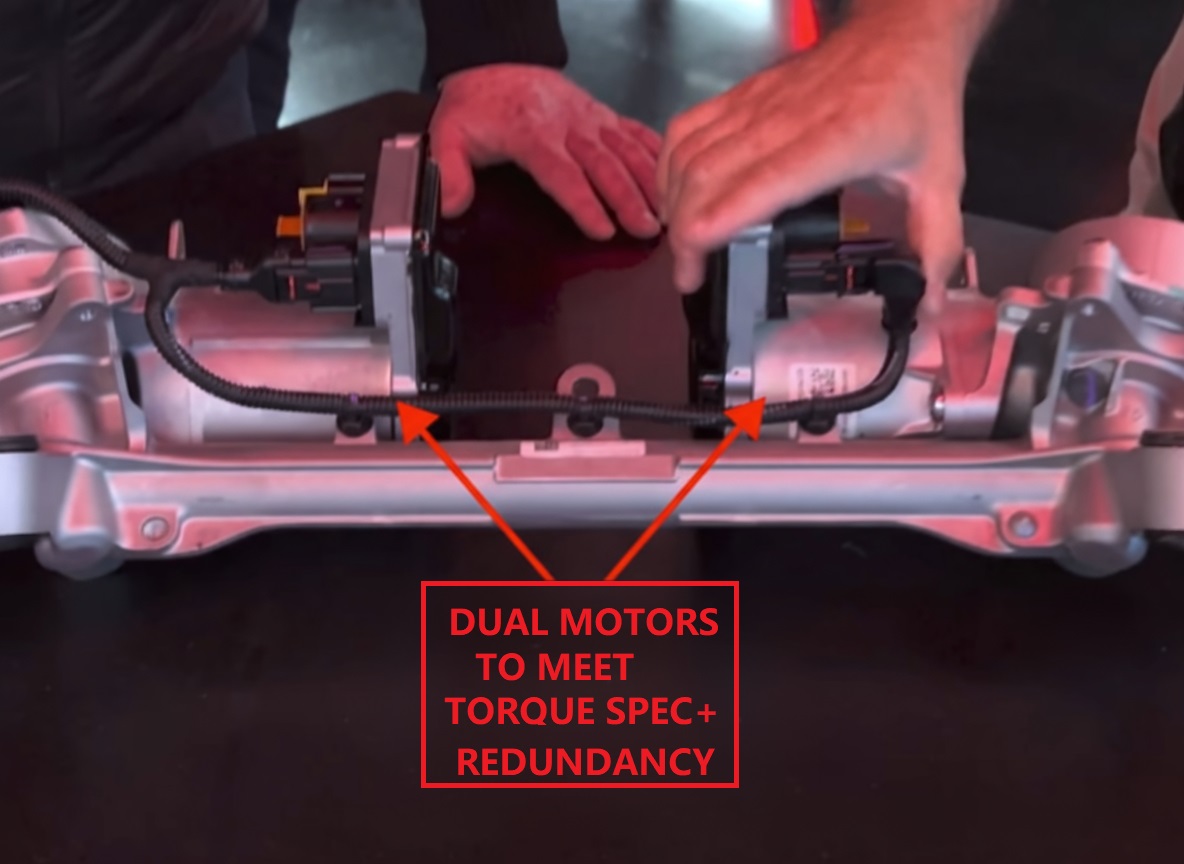

Cybertruck's steer-by-wire uses two motors, each capable of producing approximately 50%–60% of maximum torque at low-speed parking maneuvers. If one motor fails, the other can provide redundancy. A separate motor drives the rear-steer feedback mechanism to simulate steering feel for the driver. This simulated feedback is important because it helps the driver sense wheel behavior and provides tire-ground interaction data to the vehicle control unit, enabling improved traction and handling during steering maneuvers.

Communication network

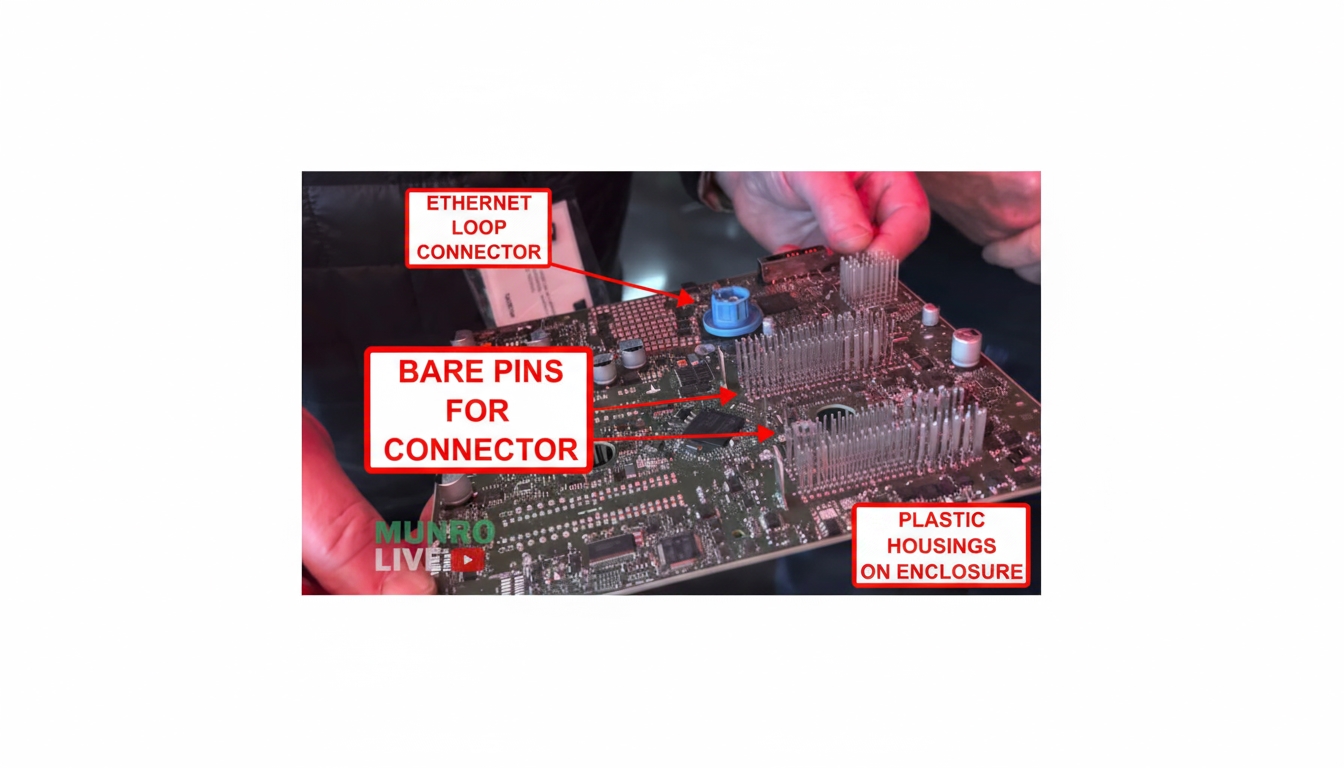

Because steer-by-wire relies on timely and reliable signal transmission, the underlying vehicle network is critical. The Cybertruck replaces traditional CAN communication with Ethernet, using a gigabit Ethernet system to transport data. This provides low latency on the order of sub-milliseconds, sufficient for steering control, and offers bandwidth for multiple controllers to communicate in real time.

Compared with CAN, Ethernet offers higher bandwidth and can be wired in a daisy-chain topology across the vehicle. With power-over-Ethernet (PoE), the same Ethernet interface can supply low-voltage power to devices, potentially reducing harness complexity and cost as in-vehicle Ethernet and advanced driver features become more widely adopted.

Summary

Steer-by-wire is a mature concept that faces practical challenges when implemented at vehicle scale. Early production attempts by various manufacturers encountered issues, reflecting the difficulty of replacing mechanical sensor-actuator chains with electrical signaling while meeting safety requirements. Because electrical faults can arise from many sources, broad market validation and time are necessary before widespread adoption. If implementations prove reliably stable, integration of skateboard chassis platforms and related electrified vehicle architectures may advance further.

ALLPCB

ALLPCB