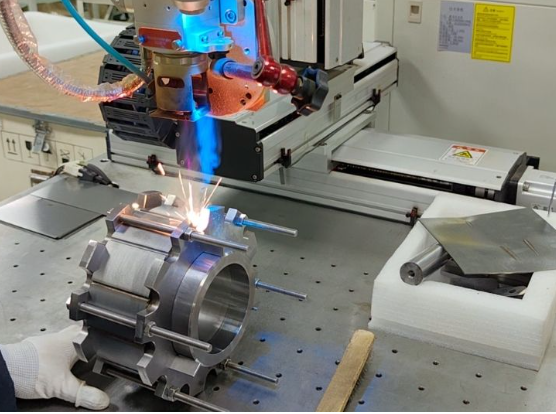

Preparation before welding

First, before using laser welding for EV motor stator cores, perform a comprehensive inspection and maintenance of the equipment. Check key parameters such as laser power and beam quality, verify the operating status of the welding robot, confirm sensor accuracy, and ensure welding tools are in good condition. Only with properly functioning equipment can welding stability and joint reliability be ensured.

Second, prepare materials and consumables. Select appropriate silicon steel, tooling, and auxiliary materials, and conduct quality inspection and conditioning. Consider factors such as electrical conductivity, thermal conductivity, and corrosion resistance when choosing welding materials to ensure joint stability and reliability. Equip suitable fixtures and auxiliary items, such as clamps, tungsten pins, and shielding gas, to support fixation and protection during welding.

Also establish and optimize detailed process procedures, including determination of welding parameters, definition of welding paths, and specification of welding sequence. Parameter selection should account for material properties and joint geometry to ensure process stability and joint quality. Path planning must consider joint shape, dimensions, and positioning to maintain integrity. For the interface between fixture and weld, a copper insert is commonly used; because its melting point differs from the fixture, this reduces the risk of fusion with the fixture and helps ensure joint reliability.

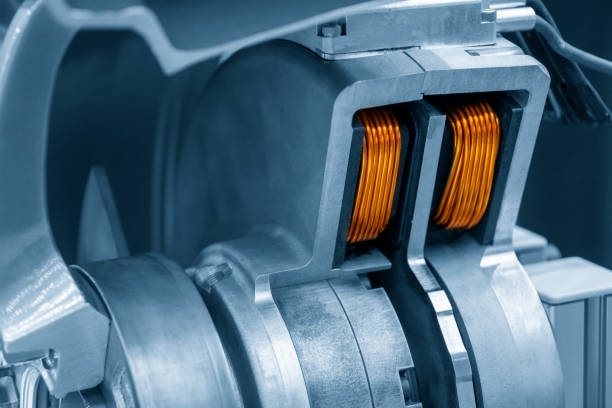

Parameter control during welding

Parameter control is critical for laser welding of EV motor stator cores. Proper control improves weld quality, increases efficiency, reduces energy consumption, and minimizes defects such as porosity.

Accurate measurement and control of process parameters are required. These include laser power, welding speed, and beam diameter. Laser power is a primary factor affecting weld quality; both excessive and insufficient power can cause defects. Use precise power measurement and control systems to monitor laser output in real time and adjust according to welding requirements. Welding speed must also be precisely controlled, since speeds that are too high or too low negatively affect quality. Beam diameter should be controlled by the optical system to ensure accurate weld placement and consistent bead quality.

Parameter control must also address melt pool formation and stability. Controlled combinations of welding speed and power help manage melt pool depth and width and maintain a stable melt pool. In addition, coordinated motion control of the welding robot is necessary to ensure accurate and stable path following, which further optimizes weld quality.

Finally, account for material properties and welding environment. Different materials vary in melting point and thermal conductivity, so adjust parameters accordingly. Environmental factors such as temperature and humidity can also influence weld quality; include temperature and humidity monitoring and control to maintain a stable welding environment.

Post-weld quality inspection

Post-weld inspection verifies joint integrity, strength, durability, and the presence of internal defects. Common inspection methods include:

Visual inspection. This straightforward method checks for incomplete penetration, obvious surface defects, joint misalignment, and improper stacking angles. Visual inspection can be supported by photographic tracking and comparison techniques and by inspection from experienced welders.

Dimensional inspection. Measure joint geometry to determine compliance with design requirements. Dimensional checks can use tools such as line-scan CCD cameras combined with coordinate measuring machines (CMMs) to measure and compare weld geometry against standards.

Non-destructive testing (NDT). NDT detects internal defects without damaging parts. Typical methods include ultrasonic testing, radiographic inspection, and magnetic particle inspection. These methods can reveal cracks, porosity, and slag inclusions, improving joint quality assurance.

Mechanical testing. Evaluate joint strength and reliability through tensile, bend, and compression tests. Mechanical testing requires specialized equipment such as a universal testing machine. These tests determine whether welded joints can withstand specified service loads.

ALLPCB

ALLPCB