Are you wondering how the size of a printed circuit board (PCB), especially when it's very small, impacts manufacturing costs? The simple answer is that smaller PCBs can be both cost-effective and expensive, depending on various factors like design complexity, production volume, and fabrication constraints. In this comprehensive guide, we’ll dive deep into the relationship between PCB size and cost, focusing on minimum PCB size pricing, manufacturing cost factors, and small PCB cost optimization strategies. Whether you're an engineer or a product designer, understanding these elements can help you make informed decisions to balance performance and budget.

Introduction to PCB Size and Cost Dynamics

PCBs are the backbone of modern electronics, and their size plays a critical role in determining manufacturing expenses. As devices become more compact—think wearable tech, IoT sensors, and medical implants—engineers often need to design smaller PCBs. However, shrinking the size doesn't always mean shrinking the cost. In fact, minimum PCB size pricing can sometimes surprise you with higher expenses due to specialized processes and equipment needed for tiny boards.

In this blog, we’ll break down the key factors that influence PCB manufacturing cost when dealing with small sizes. From panel utilization to fabrication challenges, we’ll explore actionable ways to optimize costs without sacrificing quality. Let’s get started with the basics of how size affects pricing in PCB production.

Understanding Minimum PCB Size and Its Pricing Challenges

When we talk about minimum PCB size, we’re often referring to boards smaller than 50mm x 50mm, sometimes as tiny as 10mm x 10mm or less for specialized applications. These dimensions are common in compact electronics but come with unique pricing challenges during manufacturing.

One major factor in minimum PCB size pricing is panelization. Manufacturers produce multiple PCBs on a single large panel to maximize efficiency. However, very small PCBs may not fit neatly into standard panel layouts, leading to wasted space. For instance, if a panel can hold 100 standard-sized boards but only 80 tiny ones due to spacing requirements, the cost per board increases because the wasted material adds to the overall expense.

Additionally, small PCBs often require tighter tolerances and precision during fabrication. Cutting, drilling, and routing these boards demand advanced machinery and slower processing times to avoid errors, which can drive up costs. For example, a standard PCB might be processed at a rate of 100 units per hour, while a batch of tiny boards could drop to 50 units per hour due to the need for meticulous handling.

Key PCB Manufacturing Cost Factors for Small Boards

Beyond size alone, several manufacturing factors influence the cost of small PCBs. Understanding these can help you optimize your design for affordability. Let’s explore the most significant PCB manufacturing cost factors related to size.

1. Material Utilization and Waste

As mentioned earlier, small PCBs can lead to inefficient panel utilization. Manufacturers often charge based on the entire panel, not just the usable boards. If your design results in 30% of the panel being unused, you’re still paying for that wasted material. To mitigate this, consider designing your PCB to fit standard panel sizes or combining multiple small designs into a single order to maximize space.

2. Fabrication Complexity

Smaller boards often mean denser layouts with finer traces and smaller vias. For example, a small PCB might require trace widths as narrow as 0.1mm and via diameters of 0.2mm, compared to 0.2mm traces and 0.4mm vias on a larger board. These specifications demand advanced laser drilling and etching processes, which are more expensive than standard methods. The tighter the design constraints, the higher the fabrication price.

3. Handling and Assembly Challenges

Tiny PCBs are harder to handle during assembly. Automated pick-and-place machines may need custom fixtures or slower speeds to place components accurately on a board smaller than 20mm x 20mm. Manual assembly, if required, also increases labor costs due to the precision needed. These handling challenges can add a significant percentage to the overall cost, sometimes 10-20% more than for larger boards.

4. Testing and Quality Control

Ensuring the quality of small PCBs often requires specialized testing equipment. For instance, automated optical inspection (AOI) systems may need higher resolution settings to detect defects on miniature boards, increasing inspection time and cost. Electrical testing for signal integrity on a dense, small PCB might also involve custom test fixtures, further adding to expenses.

Small PCB Cost Optimization Strategies

While small PCBs can be expensive to manufacture, there are several ways to optimize costs without compromising on functionality. Here are practical tips for small PCB cost optimization that you can apply to your next project.

1. Optimize Panel Layouts

Work with your manufacturer to arrange multiple small PCBs on a panel efficiently. Some manufacturers offer panelization tools or services to help you fit as many boards as possible into a single panel. For example, rotating designs or nesting them closely can reduce waste by up to 15-20%, directly lowering the cost per board.

2. Simplify Design Where Possible

While small size often means dense layouts, avoid overcomplicating the design. Use larger trace widths and spacing if the application allows. For instance, opting for 0.15mm traces instead of 0.1mm can reduce fabrication complexity and cost by avoiding the need for specialized equipment. Balance size constraints with manufacturability to keep expenses in check.

3. Choose Standard Materials and Processes

Exotic materials or non-standard processes can skyrocket costs for small PCBs. Stick to common substrate materials like FR-4 and standard layer counts (e.g., 2 or 4 layers) unless your design absolutely requires high-frequency materials or additional layers. Standard processes can save you 10-30% compared to custom options.

4. Order in Higher Volumes

Manufacturing costs per unit often decrease with higher order quantities. For small PCBs, the setup costs (e.g., tooling, programming machines) are spread across more units in larger batches. Ordering 500 units instead of 50 can reduce the per-unit cost by as much as 40%, making bulk orders a smart choice for cost optimization.

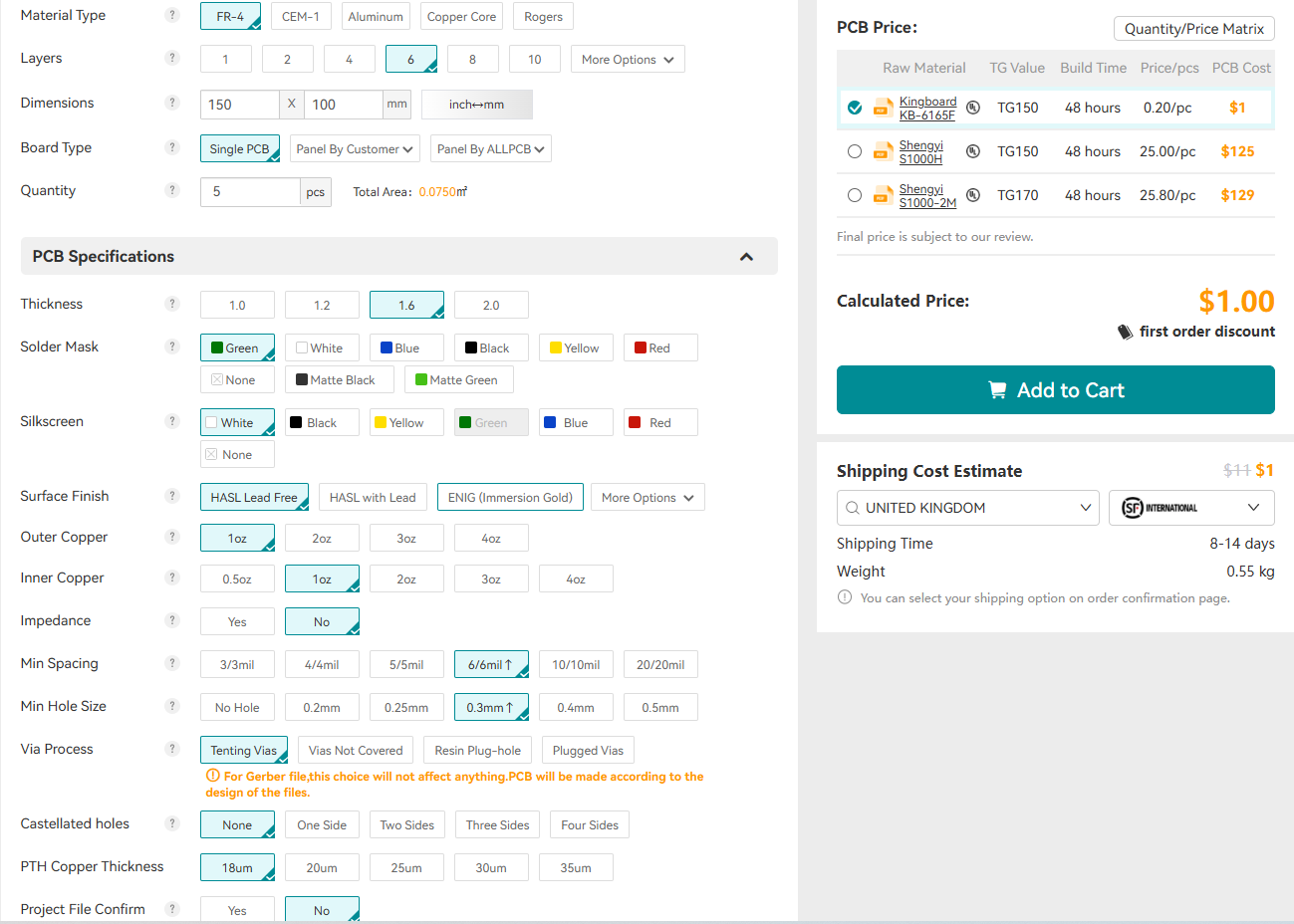

How PCB Fabrication Price Varies with Size and Volume

PCB fabrication price is not just about size; it’s also heavily influenced by production volume and the specific requirements of the board. Let’s look at how these elements interact with small PCB manufacturing.

For low-volume production (e.g., prototypes or batches under 100 units), the cost per board is typically higher due to fixed setup fees. A small PCB might cost $5 per unit in a batch of 50, but only $2 per unit in a batch of 500, even though the size remains the same. This economy of scale is critical when planning your production run.

Moreover, very small PCBs can sometimes benefit from lower material costs since they use less raw substrate. However, this saving is often offset by the increased labor and precision required. For example, a 10mm x 10mm PCB might use only 1% of the material of a 100mm x 100mm board, but its fabrication price could be 50% higher due to the specialized processes involved.

Balancing Performance and Cost in Small PCB Design

Designing a small PCB is often a balancing act between achieving the desired performance and keeping costs manageable. For instance, in high-frequency applications like RF modules, a small PCB might need microstrip lines with specific impedance values (e.g., 50 ohms) to ensure signal integrity. Achieving this on a tiny board requires precise control over trace geometry and dielectric thickness, which can increase costs by 20-30% compared to a standard design.

To balance this, consider hybrid approaches. Use a small PCB for critical high-density areas and connect it to a larger, cheaper board for less critical components. This modular design can reduce overall expenses while maintaining performance where it matters most.

Conclusion: Making Informed Decisions on Small PCB Costs

The relationship between PCB size and cost is complex, especially when dealing with minimum PCB size pricing. Small PCBs can lead to higher manufacturing expenses due to inefficient panel utilization, fabrication complexity, and handling challenges. However, with the right strategies—such as optimizing panel layouts, simplifying designs, choosing standard materials, and ordering in bulk—you can achieve significant small PCB cost optimization.

Understanding these PCB manufacturing cost factors empowers you to make smarter decisions for your projects. Whether you're designing for a compact IoT device or a medical sensor, balancing size, performance, and budget is key. By focusing on efficient design and production practices, you can minimize costs while ensuring your PCB meets the highest standards of quality and reliability.

At ALLPCB, we’re committed to helping you navigate these challenges with expert guidance and cost-effective solutions. Keep these tips in mind for your next project, and you’ll be well on your way to mastering the cost of small PCBs.

ALLPCB

ALLPCB