If you're diving into electronics design and wondering how to make your projects future-proof, upgradable PCBs (Printed Circuit Boards) are the answer. But what exactly are upgradable PCBs, why should you consider them, and how can you design one for your next project? In short, upgradable PCBs are circuit boards designed with flexibility in mind, allowing for easy updates or component replacements without redesigning the entire board. They save time, reduce costs, and keep your designs adaptable to new technology. In this comprehensive guide, we'll explore everything you need to know about upgradable PCBs, from their benefits in electronics manufacturing to step-by-step tips for creating customizable designs.

What Are Upgradable PCBs?

Upgradable PCBs are circuit boards engineered to allow modifications or component upgrades after the initial design and manufacturing process. Unlike traditional PCBs, which are often fixed in their functionality once assembled, upgradable PCBs incorporate features like modular connectors, standardized interfaces, or extra space for future components. This design approach ensures that the board can adapt to new requirements, whether it's swapping out a microcontroller for a more powerful one or adding new sensors as technology evolves.

Think of an upgradable PCB as a foundation that can grow with your project. For instance, in consumer electronics like smartphones or IoT devices, manufacturers often use modular designs to replace outdated processors or memory chips without scrapping the entire board. This concept is now accessible to hobbyists, engineers, and small-scale manufacturers thanks to advancements in electronics design tools and manufacturing techniques.

Why Choose Upgradable PCBs for Electronics Design?

Designing with upgradability in mind offers several advantages, especially in a fast-paced tech world where components become obsolete quickly. Let's break down the key reasons to prioritize upgradable PCBs in your next project, focusing on the "how and why" of electronics upgrades.

1. Cost Efficiency Over Time

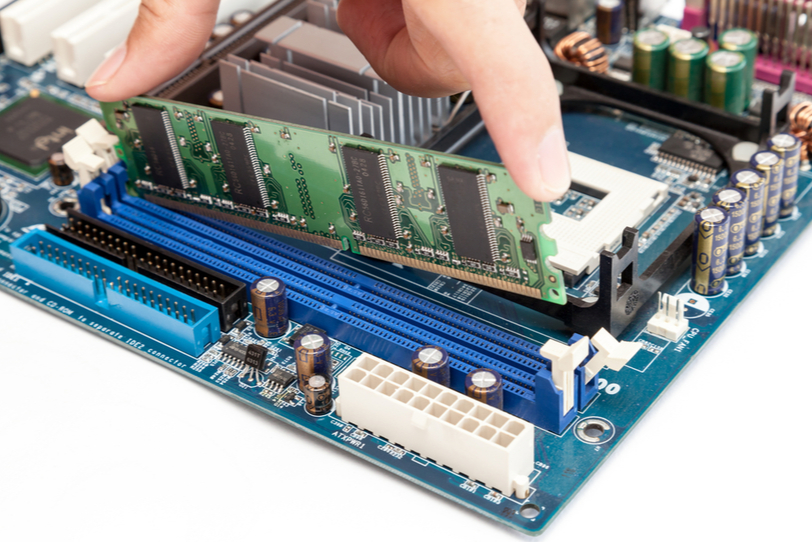

Redesigning and remanufacturing a PCB every time a component needs an upgrade can be expensive. Upgradable PCBs minimize these costs by allowing you to swap out specific parts without touching the core board. For example, if a new microcontroller with better processing speed (say, from 16 MHz to 32 MHz) becomes available, you can replace just that chip if your PCB is designed with a compatible socket or connector.

2. Future-Proofing Your Designs

Technology evolves rapidly. A sensor that operates at 3.3V today might be replaced by a more efficient 1.8V version in a year. Upgradable PCBs let you adapt to these changes by incorporating flexible voltage regulators or adjustable pin configurations. This ensures your design remains relevant without starting from scratch.

3. Simplified Testing and Prototyping

During the prototyping phase, you might need to test multiple components to find the best fit. Upgradable PCBs make this process easier by allowing you to plug in different modules or chips without soldering or desoldering. This can save hours of work and reduce the risk of damaging the board.

4. Environmental Benefits

Electronics waste is a growing concern. By designing PCBs that can be upgraded rather than replaced, you reduce the number of discarded boards, contributing to a more sustainable approach in electronics manufacturing. Reusing the same board for multiple iterations of a project cuts down on material waste significantly.

How to Design Upgradable PCBs: A Step-by-Step Tutorial

Creating an upgradable PCB might sound complex, but with the right approach, it's a manageable task even for those new to electronics design. This "upgradable PCBs tutorial" will walk you through the process, ensuring your next project is both customizable and adaptable.

Step 1: Define Your Upgrade Needs

Start by identifying which components are most likely to need upgrades. For instance, microcontrollers, communication modules (like Wi-Fi or Bluetooth chips), and sensors often see frequent updates in performance or standards. Make a list of these components and consider how often they might change over the lifespan of your product.

Step 2: Choose Modular Design Elements

Incorporate modular connectors or sockets instead of soldering components directly onto the board. For example, use DIP (Dual Inline Package) sockets for microcontrollers or standardized headers for communication modules. This allows you to swap parts without needing specialized tools. Ensure the connectors support a range of pin counts and voltages (e.g., 3.3V to 5V) to accommodate future components.

Step 3: Plan for Extra Space and Flexibility

Leave additional space on your PCB layout for future additions. If you think you might add a new sensor later, include unused pads or mounting holes in your design. Also, design power traces to handle higher currents (e.g., up to 2A instead of 1A) to support more power-hungry components down the line.

Step 4: Use Standardized Interfaces

Opt for widely used interfaces like I2C, SPI, or USB for connecting modules. These standards are supported by a vast range of components, making it easier to find compatible upgrades. For instance, an I2C interface can connect to various sensors with minimal redesign, even if the specific sensor model changes.

Step 5: Incorporate Firmware Update Capabilities

Upgradability isn't just about hardware. Design your PCB to support firmware updates through accessible programming ports or over-the-air (OTA) capabilities. This ensures that even if the hardware stays the same, the software running on it can be updated to improve performance or add features.

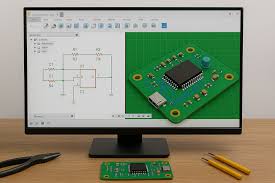

Step 6: Test and Validate Your Design

Before finalizing your PCB, prototype it using a breadboard or simulation software to ensure all modular components fit and function as expected. Check for signal integrity issues, especially if you're using high-speed interfaces (e.g., signal speeds above 50 MHz), as poor trace design can lead to interference or data loss.

Key Considerations in Customizable PCBs for Electronics Design

When focusing on customizable PCBs in electronics design, there are a few critical factors to keep in mind to ensure your board meets both current and future needs.

1. Component Compatibility

Always check the datasheets of potential upgrade components to ensure compatibility with your PCB's voltage levels, pin configurations, and thermal requirements. For example, if your board supplies 3.3V but a future component requires 1.8V, you'll need a voltage regulator or level shifter in place.

2. Signal Integrity and Impedance

For high-speed designs, maintain proper impedance matching to avoid signal degradation. If you're upgrading to a faster microcontroller (e.g., one operating at 100 MHz), ensure your traces are designed with controlled impedance (typically around 50 ohms for digital signals) to prevent reflections and noise.

3. Manufacturing Scalability

Work with a reliable manufacturing partner who can produce PCBs with the precision needed for modular designs. Ensure they support small-batch prototyping as well as larger production runs if your project scales. Clear communication about design files and specifications is crucial to avoid errors during production.

4. Cost vs. Flexibility Trade-Off

While upgradable designs save money long-term, they can increase initial costs due to extra connectors or unused space. Balance your budget with the expected frequency of upgrades. For low-volume projects, the added cost might be minimal compared to the benefits of flexibility.

Applications of Upgradable PCBs in Electronics Manufacturing

Upgradable PCBs have a wide range of applications across industries, making them a valuable choice in electronics manufacturing. Here are a few examples where they shine:

- IoT Devices: Internet of Things devices often need updates to communication protocols or sensors. Upgradable PCBs allow manufacturers to refresh these components without redesigning the entire product.

- Consumer Electronics: Products like gaming consoles or smart home gadgets benefit from modular designs, enabling users to upgrade memory or processing power as needed.

- Industrial Automation: Control systems in factories may require new sensors or actuators over time. Upgradable PCBs make these swaps seamless, minimizing downtime.

- Medical Devices: In healthcare, equipment must adapt to new standards or technologies. Upgradable designs ensure compliance without replacing entire systems.

Challenges and Solutions in Designing Upgradable PCBs

While the benefits are clear, designing upgradable PCBs comes with challenges. Here's how to address common issues:

Challenge 1: Increased Complexity

Modular designs can complicate the layout, increasing the risk of errors. Solution: Use design software with built-in validation tools to check for issues like trace spacing or connector alignment before manufacturing.

Challenge 2: Higher Initial Costs

Extra connectors and space can raise costs upfront. Solution: Focus on components with the highest likelihood of upgrades to avoid over-engineering unnecessary parts of the board.

Challenge 3: Compatibility Risks

Future components might not fit perfectly with your design. Solution: Stick to widely adopted standards and interfaces to maximize the pool of compatible parts.

Conclusion: Embrace Upgradable PCBs for Smarter Electronics Design

Upgradable PCBs are a game-changer for anyone involved in electronics design and manufacturing. They offer a cost-effective, sustainable, and flexible approach to creating products that can evolve with technology. By understanding what upgradable PCBs are, why they matter, and how to design them, you can ensure your next project is ready for the future. Whether you're a hobbyist tinkering with IoT devices or a professional engineer working on industrial systems, incorporating upgradability into your designs will save time, money, and resources in the long run.

Start small by identifying key components for upgrades, use modular connectors, and plan for flexibility in your layouts. With these steps, you'll be well on your way to mastering customizable PCBs in electronics design. Partnering with a trusted manufacturing service can further streamline the process, ensuring your vision becomes a reality with precision and quality.

ALLPCB

ALLPCB