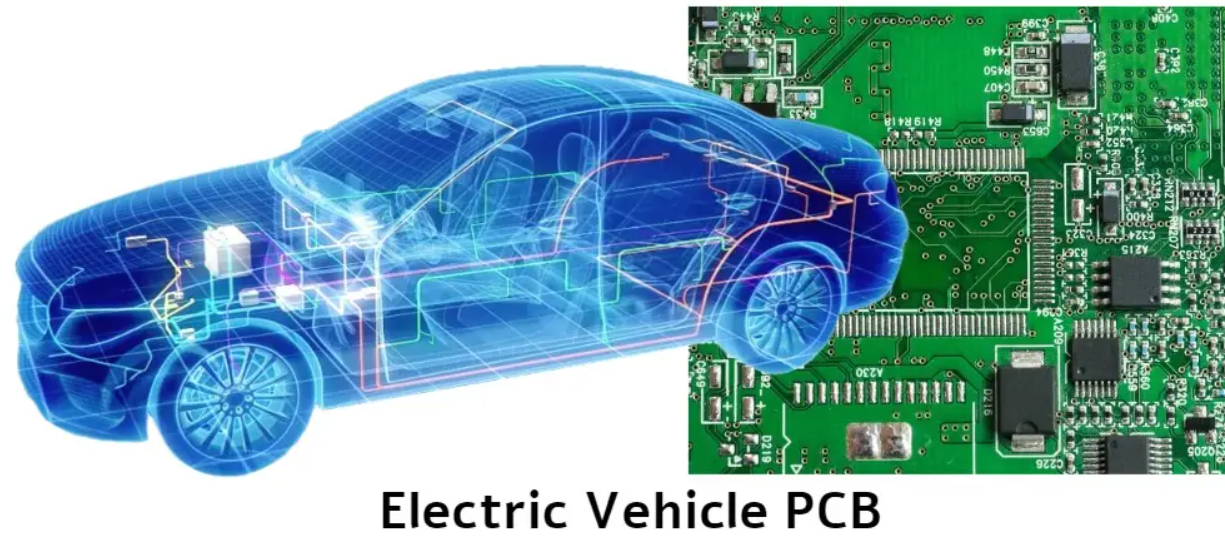

In the fast-evolving automotive industry, printed circuit boards (PCBs) are the backbone of modern vehicle electronics, powering everything from safety systems to infotainment features. For manufacturers, the challenge lies in PCB mass production for automotive applications while adhering to stringent quality standards. How can companies ensure high reliability and meet automotive PCB manufacturing standards? The answer lies in a combination of advanced design, rigorous testing, and the use of automotive-grade materials tailored to withstand harsh conditions.

In this comprehensive guide, we’ll dive deep into the world of automotive PCB production. From understanding the importance of high-reliability PCBs to exploring PCB testing for automotive applications, we’ll cover the key aspects that ensure your boards meet the demanding requirements of modern vehicles. Whether you're an engineer or a procurement specialist, this blog will provide actionable insights into automotive-grade PCB materials, assembly processes, and quality assurance.

Why Automotive PCBs Require Stringent Quality Standards

Automotive PCBs are at the heart of critical systems like anti-lock braking systems (ABS), airbag controls, engine management, and advanced driver assistance systems (ADAS). Unlike consumer electronics, these boards must operate flawlessly under extreme conditions, including temperature swings from -40°C to 125°C, high humidity, and constant vibration. A single failure can lead to catastrophic consequences, making high reliability in PCB automotive applications non-negotiable.

The automotive industry follows strict regulations and standards to ensure safety and performance. Standards like ISO/TS 16949 (now integrated into IATF 16949) set the benchmark for quality management in automotive manufacturing. These guidelines demand that every stage of PCB production, from design to assembly, prioritizes durability, precision, and traceability. Meeting these automotive PCB manufacturing standards is not just about compliance—it's about building trust with manufacturers and end-users.

Key Challenges in PCB Mass Production for Automotive Applications

Mass-producing PCBs for automotive use comes with unique challenges. Let’s explore some of the most critical hurdles and how they impact production:

- Harsh Operating Environments: Automotive PCBs must endure extreme heat, cold, and moisture. For instance, a PCB in an engine control module might face temperatures up to 150°C near the engine block, requiring materials with high thermal stability.

- Vibration and Mechanical Stress: Constant road vibrations can loosen components or crack solder joints. Boards must be designed with robust mounting techniques and flexible materials in high-stress areas.

- Signal Integrity: High-speed signals in systems like radar or ADAS require precise impedance control, often within ±10% tolerance (e.g., 50 ohms for RF signals), to prevent data loss or interference.

- Regulatory Compliance: Automotive PCB manufacturing standards demand full traceability of materials and processes, adding complexity to mass production workflows.

Overcoming these challenges requires a deep understanding of automotive-grade PCB materials and advanced manufacturing techniques, which we’ll discuss in the following sections.

Automotive-Grade PCB Materials: Building for Durability

The choice of materials is a cornerstone of high-reliability PCB automotive design. Automotive-grade PCB materials must offer excellent thermal resistance, mechanical strength, and electrical performance. Here are some commonly used materials and their benefits:

- FR-4 with High Tg: Standard FR-4 materials with a glass transition temperature (Tg) of 170°C or higher are often used for less demanding automotive applications. They provide a cost-effective balance of thermal and mechanical properties.

- Polyimide: For high-temperature environments, polyimide substrates withstand temperatures up to 260°C, making them ideal for engine control units and powertrain systems.

- Ceramic-Based Materials: These offer superior heat resistance and dimensional stability, often used in high-power applications. However, they come with higher costs and manufacturing complexity.

- Metal-Core PCBs (MCPCBs): Featuring aluminum or copper cores, MCPCBs excel in heat dissipation for LED lighting and power electronics in vehicles.

Selecting the right material depends on the specific application within the vehicle. For instance, a PCB in a dashboard infotainment system may prioritize cost with FR-4, while a safety-critical system like ABS requires polyimide for added reliability under stress.

Design Considerations for High-Reliability PCB Automotive Applications

Designing PCBs for automotive use is a meticulous process that directly impacts reliability and manufacturability. Here are key guidelines to follow during the design phase:

- Thermal Management: Efficient heat dissipation prevents component failure. Incorporate thermal vias, heat sinks, and copper planes to manage temperatures, especially in high-power circuits where current densities can reach 10 A/mm2.

- Component Placement: Position components to minimize signal interference and ensure easy assembly. For example, keep high-frequency components away from power lines to avoid electromagnetic interference (EMI).

- Vibration Resistance: Use flexible PCB sections or conformal coatings to absorb vibrations. Secure heavy components with additional mounting points to prevent detachment during operation.

- Impedance Matching: For high-speed signals in ADAS, maintain consistent impedance (e.g., 100 ohms for differential pairs) to ensure signal integrity over long traces.

By addressing these factors during the design stage, manufacturers can reduce errors and improve the longevity of automotive PCBs.

PCB Assembly for Automotive: Precision and Consistency

PCB assembly for automotive applications demands precision to ensure every board meets quality standards during mass production. Surface-mount technology (SMT) is widely used due to its efficiency and ability to handle high-density designs. However, automotive assembly requires additional considerations:

- Automated Optical Inspection (AOI): AOI systems detect soldering defects, misaligned components, and other issues with up to 99.9% accuracy, ensuring consistency across thousands of units.

- Reflow Soldering Profiles: Tailor reflow profiles to match automotive-grade components, often requiring peak temperatures of 260°C for lead-free solder to meet RoHS compliance.

- Conformal Coating: Apply protective coatings to shield PCBs from moisture, dust, and chemical exposure, extending their lifespan in harsh environments.

- Traceability: Implement barcode or RFID tracking for each PCB to comply with automotive PCB manufacturing standards, allowing full visibility from production to installation.

These assembly practices are critical for maintaining high reliability in PCB automotive systems, especially when producing at scale.

PCB Testing for Automotive Applications: Ensuring Zero Defects

Testing is a vital step in ensuring that automotive PCBs meet the stringent requirements of safety and performance. PCB testing for automotive applications involves multiple layers of validation to catch defects before they reach the field. Here are the primary testing methods:

- In-Circuit Testing (ICT): ICT verifies component placement and electrical connections, identifying issues like open circuits or incorrect resistor values with a test coverage of over 90%.

- Functional Testing: Simulates real-world operating conditions to ensure the PCB performs as intended, such as testing an ABS control board under rapid braking scenarios.

- Environmental Stress Testing: Subjects PCBs to extreme temperatures (e.g., -40°C to 125°C), humidity (up to 95% RH), and vibration (up to 20G) to confirm durability.

- Burn-In Testing: Operates the PCB under maximum load for extended periods (e.g., 48 hours at 85°C) to detect early failures before deployment.

These rigorous testing protocols ensure that every PCB meets automotive standards, reducing the risk of field failures and costly recalls.

Meeting Automotive PCB Manufacturing Standards with Quality Assurance

Quality assurance (QA) is the foundation of successful PCB mass production for automotive applications. Adhering to automotive PCB manufacturing standards like IATF 16949 requires a robust QA system that covers every aspect of production. Key elements include:

- Process Control: Standardize manufacturing processes to maintain consistency, such as controlling lamination pressure within ±5% to avoid delamination issues.

- Supplier Audits: Verify that raw material suppliers meet automotive-grade specifications, ensuring no substandard components enter the supply chain.

- Documentation: Maintain detailed records of design files, test results, and production logs to support traceability and compliance audits.

- Continuous Improvement: Use failure mode and effects analysis (FMEA) to identify potential risks and implement corrective actions, reducing defect rates to below 50 parts per million (PPM).

A strong QA framework not only ensures compliance but also builds confidence in the reliability of automotive PCBs.

The Future of Automotive PCB Production

As vehicles become more connected and autonomous, the demand for advanced PCBs will continue to grow. Emerging trends like electric vehicles (EVs), 5G connectivity, and vehicle-to-everything (V2X) communication will push the boundaries of PCB design and manufacturing. For instance, EV battery management systems (BMS) require PCBs with high current-carrying capacity (up to 100A) and precise voltage monitoring (±0.1V accuracy).

To stay ahead, manufacturers must invest in cutting-edge technologies like high-density interconnect (HDI) PCBs, which support micro-via drilling with diameters as small as 0.1mm, and advanced materials that offer even greater thermal and electrical performance. By embracing innovation, companies can meet the evolving needs of the automotive sector.

Conclusion: Partnering for High-Reliability Automotive PCBs

PCB mass production for automotive applications is a complex but essential process that demands precision, durability, and strict adherence to quality standards. From selecting automotive-grade PCB materials to implementing rigorous PCB testing for automotive applications, every step plays a critical role in ensuring high-reliability PCB automotive systems. By focusing on design optimization, advanced assembly techniques, and comprehensive quality assurance, manufacturers can deliver boards that power the future of transportation.

At ALLPCB, we understand the unique challenges of automotive PCB production. Our expertise in meeting automotive PCB manufacturing standards and delivering tailored solutions ensures that your projects achieve the highest levels of performance and reliability. Whether you're developing safety-critical systems or next-generation infotainment, we're here to support your success with end-to-end PCB services.

ALLPCB

ALLPCB