Are you looking for the best solvent for PCB cleaning? Or maybe you're debating between IPA vs acetone for PCB cleaning? Cleaning printed circuit boards (PCBs) is a critical step in ensuring their performance and longevity. Whether you're removing flux residue after soldering or tackling other contaminants, choosing the right solvent is essential for protecting delicate components and maintaining functionality. In this guide, we'll explore safe PCB cleaning solvents, discuss solvent compatibility with PCB components, and provide solvent disposal guidelines for PCB cleaning. Let's dive into everything you need to know to keep your boards spotless and functional.

Why PCB Cleaning Matters

PCBs are the backbone of modern electronics, and any residue or contamination on their surface can lead to serious issues. Flux, a common substance used during soldering, helps create strong connections but leaves behind sticky residue that can attract dust, moisture, and other contaminants. If not cleaned properly, this residue can cause corrosion, short circuits, or signal interference, leading to failure rates as high as 30% in poorly maintained boards, according to industry studies.

Cleaning your PCB isn't just about aesthetics; it’s about ensuring reliability. A clean board reduces the risk of electrical failures and extends the lifespan of your device. But not all cleaning methods or solvents are created equal. Using the wrong solvent can damage components or leave harmful residues behind. That’s why understanding your options and their implications is so important.

What to Look for in a PCB Cleaning Solvent

Before we dive into specific solvents, let’s cover the key factors to consider when choosing a cleaning agent for your PCB:

- Effectiveness: The solvent should effectively remove flux, solder paste, and other contaminants without leaving residue.

- Safety: It should be non-toxic and safe for both the user and the environment.

- Compatibility: The solvent must not damage PCB components, coatings, or materials like plastics and metals.

- Drying Time: Quick evaporation is ideal to prevent moisture-related issues.

- Availability and Cost: The solvent should be easy to source and budget-friendly for regular use.

With these criteria in mind, let’s explore some of the most common solvents used for PCB cleaning and see how they stack up, especially when comparing IPA vs acetone for PCB cleaning.

Best Solvents for PCB Cleaning

1. Isopropyl Alcohol (IPA) - The Go-To Choice

Isopropyl Alcohol, commonly known as IPA, is widely regarded as the best solvent for PCB cleaning by hobbyists and professionals alike. Typically available in concentrations of 70% to 99%, IPA is effective at dissolving flux residue, grease, and other contaminants without harming most PCB materials.

Why IPA Works:

- It evaporates quickly, leaving no residue behind.

- It’s relatively safe to use with proper ventilation and is less aggressive than other solvents.

- It’s compatible with most PCB components, including sensitive plastics and coatings.

How to Use: Apply IPA with a soft brush or cotton swab to gently scrub away residue. Use a lint-free cloth to wipe the board dry. For best results, opt for a concentration of 90% or higher to minimize water content, which can lead to corrosion if left on the board.

Caution: Always work in a well-ventilated area, as IPA fumes can be harmful if inhaled in large amounts. Also, ensure the board is powered off and disconnected to avoid any risk of short-circuiting during cleaning.

2. Acetone - A Riskier Alternative

When discussing IPA vs acetone for PCB cleaning, acetone often comes up as a potential option due to its strong solvent properties. It can effectively dissolve tough residues like rosin-based flux. However, acetone is not recommended for most PCB cleaning tasks due to significant risks.

Why Acetone Falls Short:

- It’s highly aggressive and can damage sensitive components, strip protective coatings, and dissolve certain plastics on the PCB.

- It’s extremely flammable, posing a safety hazard in environments without strict controls.

- Its environmental impact is notable, as it’s classified as a hazardous air pollutant.

When to Use: Acetone should only be considered for very specific applications where other solvents fail, and only if you’re certain it won’t harm the board’s materials. Even then, use it sparingly with extreme caution.

3. Deionized Water - A Non-Solvent Option

For those seeking safe PCB cleaning solvents, deionized water can be an effective alternative, especially for water-soluble fluxes. It’s non-toxic, environmentally friendly, and won’t damage components if used correctly.

Why It Works:

- It’s safe for most PCB materials and components.

- It’s ideal for cleaning water-soluble flux residues.

How to Use: Use a soft brush with deionized water to clean the board, then dry it thoroughly with compressed air or a lint-free cloth. Ensure no moisture remains, as it can lead to corrosion over time.

Caution: Avoid using tap water, as it contains minerals and impurities that can leave conductive residues on the board, potentially causing shorts.

4. Specialized PCB Cleaning Solutions

Beyond IPA and water, there are commercial cleaning solutions specifically formulated for PCB cleaning. These products are designed to tackle tough residues while being safe for electronic components. They often come in aerosol cans for easy application.

Why They Work:

- Formulated for specific types of flux and contaminants.

- Often include safety features like non-flammable properties.

How to Use: Follow the manufacturer’s instructions, typically involving spraying the solution onto the board and wiping it clean with a cloth or brush.

Caution: These can be more expensive than IPA, so they’re often used in professional settings rather than for hobbyist projects.

Solvent Compatibility with PCB Components

One of the most critical aspects of choosing a cleaning solvent is ensuring solvent compatibility with PCB components. Not all materials on a PCB react the same way to solvents. For instance, some plastics can melt or crack when exposed to harsh chemicals like acetone, while certain conformal coatings may degrade if cleaned with the wrong agent.

Key Tips for Compatibility:

- Check Component Datasheets: Manufacturers often specify which solvents are safe for their components. Look for this information before cleaning.

- Test on a Small Area: If you’re unsure, apply the solvent to a small, non-critical area of the board first to check for adverse reactions.

- Avoid Harsh Solvents: Solvents like acetone or toluene can damage plastics, rubber seals, and certain coatings. Stick to milder options like IPA unless absolutely necessary.

- Consider Conformal Coatings: If your PCB has a protective coating, ensure the solvent won’t strip it away. IPA is often safe for most coatings, but double-check.

By prioritizing compatibility, you can avoid costly damage. For example, replacing a single damaged IC due to solvent exposure can cost upwards of $10-$50, not to mention the time spent troubleshooting the issue.

Safe PCB Cleaning Solvents: Prioritizing Health and Environment

While effectiveness and compatibility are crucial, safety is equally important when selecting safe PCB cleaning solvents. Many solvents release fumes that can be harmful if inhaled, and some pose environmental risks if not handled properly.

Safety Tips for Solvent Use:

- Ventilation: Always work in a well-ventilated area or under a fume hood to avoid inhaling harmful vapors.

- Protective Gear: Wear gloves and safety goggles to protect your skin and eyes from accidental exposure.

- Storage: Store solvents in a cool, dry place away from heat sources to prevent fires or explosions, especially with flammable options like IPA and acetone.

Environmentally Friendly Options: If environmental impact is a concern, consider water-based cleaners or biodegradable solvents. These alternatives minimize harm to the planet while still providing effective cleaning for many types of flux and residue.

Solvent Disposal Guidelines for PCB Cleaning

Proper disposal of used solvents is just as important as choosing the right one. Improper disposal can lead to environmental contamination and even legal penalties in some regions. Here are solvent disposal guidelines for PCB cleaning to ensure you’re handling waste responsibly:

- Do Not Pour Down Drains: Never dispose of solvents like IPA or acetone by pouring them into sinks or drains. This can contaminate water supplies and violate local regulations.

- Use Designated Containers: Store used solvents in labeled, sealed containers designed for hazardous waste until they can be properly disposed of.

- Check Local Regulations: Different areas have specific rules for disposing of chemical waste. Contact your local waste management authority to find out where and how to dispose of solvents safely.

- Recycling Options: Some solvents can be recycled or reclaimed. Look for facilities that offer solvent recovery services to reduce waste.

- Minimize Waste: Use only the amount of solvent you need for each cleaning task to reduce the volume of waste generated.

Following these guidelines not only protects the environment but also ensures compliance with safety standards. For instance, improper disposal of hazardous solvents can result in fines of up to $1,000 or more in some jurisdictions.

Step-by-Step Guide to Cleaning Your PCB

Now that you know the best solvents and safety considerations, here’s a practical guide to cleaning your PCB effectively:

- Power Down and Disconnect: Ensure the PCB is completely powered off and disconnected from any power source to avoid electrical hazards.

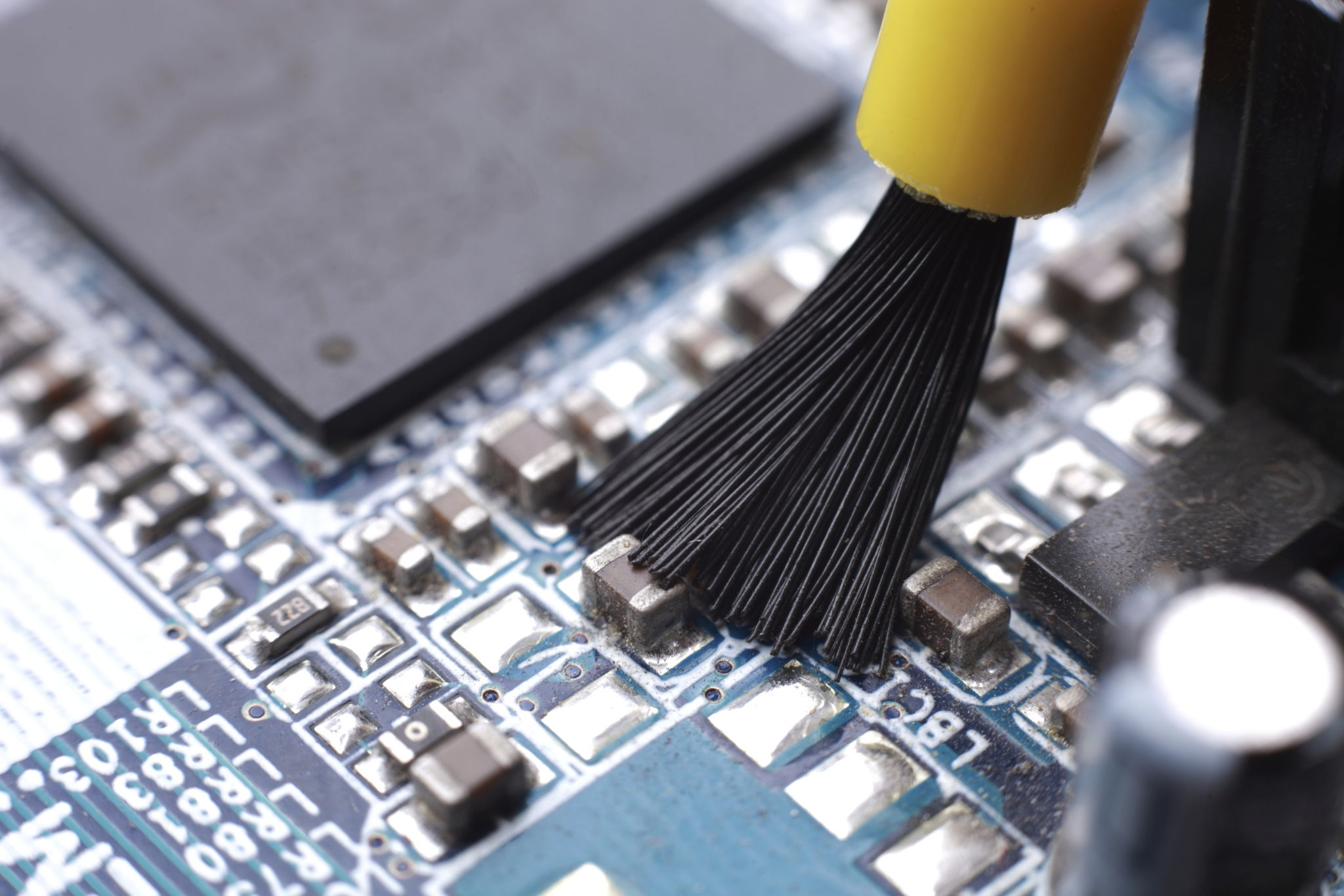

- Remove Loose Debris: Use compressed air or a soft brush to remove dust and loose particles from the board.

- Choose Your Solvent: Select a solvent based on the type of residue (e.g., IPA for rosin flux, deionized water for water-soluble flux).

- Apply Solvent: Use a cotton swab, soft brush, or lint-free cloth to apply the solvent to the affected areas. Avoid soaking the board to prevent pooling.

- Scrub Gently: Lightly scrub the residue until it dissolves. Be careful not to apply too much pressure, which could damage components.

- Wipe and Dry: Wipe the board with a clean, lint-free cloth and use compressed air to ensure no moisture or residue remains.

- Inspect: Check the board under good lighting or with a magnifying glass to ensure all residue is removed.

Following these steps can help you achieve a clean board without risking damage. For heavily soiled boards, you might need to repeat the process or use an ultrasonic cleaner for deeper cleaning.

Conclusion: Choosing the Right Solvent for Your Needs

Cleaning a PCB is a vital step in maintaining its performance and reliability, but it requires careful consideration of the solvent used. Isopropyl Alcohol (IPA) stands out as the best solvent for PCB cleaning due to its effectiveness, compatibility, and relatively low risk. When comparing IPA vs acetone for PCB cleaning, IPA is the safer and more reliable choice for most applications. For those prioritizing safety and environmental impact, safe PCB cleaning solvents like deionized water or specialized solutions are excellent alternatives.

Always ensure solvent compatibility with PCB components by checking datasheets and testing small areas before full application. Finally, follow solvent disposal guidelines for PCB cleaning to protect the environment and comply with local regulations.

By understanding your options and following best practices, you can keep your PCBs in top condition, ensuring they function flawlessly from flux to final assembly. Whether you're a hobbyist or a professional, the right cleaning approach will save you time, money, and frustration in the long run.

ALLPCB

ALLPCB