If you're an electrical engineer or hobbyist working on printed circuit board (PCB) fabrication, one of the most critical decisions you’ll make is selecting the right etchant for removing unwanted copper from your board. Two of the most common etchants are ferric chloride and cupric chloride. So, which one should you choose? For quick results and simplicity, ferric chloride is often the go-to for hobbyists due to its availability and ease of use. However, for finer lines and more controlled etching in professional settings, cupric chloride offers superior precision and reusability, though it requires more careful handling and setup.

In this detailed guide, we’ll dive deep into the comparison of ferric chloride PCB etching and cupric chloride PCB etching, exploring their properties, advantages, disadvantages, and suitability for different applications like best etchant for fine lines. Whether you’re etching a prototype at home or producing high-quality boards in a lab, this etchant comparison will help you make an informed decision about your PCB etching materials.

Understanding PCB Etching: Why Your Choice of Etchant Matters

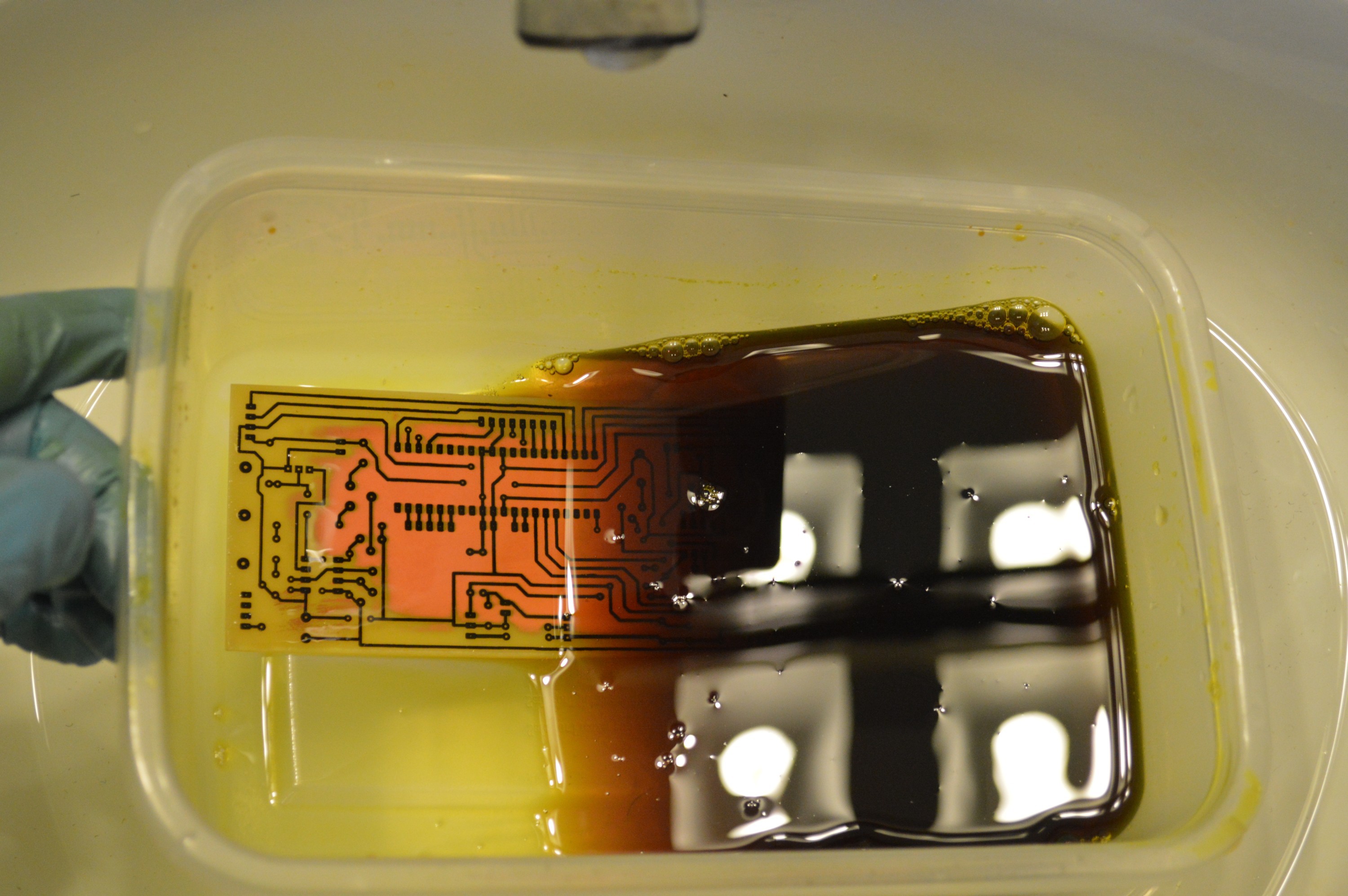

PCB etching is the process of removing excess copper from a copper-clad board to create the desired circuit pattern. The etchant chemically reacts with the unprotected copper, dissolving it while leaving the masked areas (usually covered by photoresist or toner) intact. The choice of etchant directly impacts the speed, precision, safety, and environmental footprint of your project.

Both ferric chloride (FeCl?) and cupric chloride (CuCl?) are popular choices for wet etching, but they behave differently in terms of reaction speed, line resolution, and waste management. Let’s break down each etchant to understand their strengths and weaknesses for PCB fabrication.

What Is Ferric Chloride and How Does It Work for PCB Etching?

Ferric chloride is a chemical compound often used in ferric chloride PCB etching. It appears as a dark brown or yellowish solution and is widely available in hobby stores and online. When dissolved in water, ferric chloride reacts with copper on the PCB through an oxidation-reduction reaction:

2FeCl3 + Cu → 2FeCl3 + CuCl2

In this reaction, ferric chloride (FeCl3) oxidizes the copper (Cu), turning it into copper chloride (CuCl2), while itself being reduced to ferrous chloride (FeCl3). This process effectively dissolves the unwanted copper, leaving behind your circuit pattern.

Advantages of Ferric Chloride for PCB Etching

- Availability: Ferric chloride is easy to find and relatively inexpensive, making it a popular choice for beginners and hobbyists.

- Simplicity: It requires minimal setup—just mix the solution with water (typically in a 1:1 ratio) and immerse the PCB. No complex equipment is needed.

- Speed: For standard PCBs with trace widths of 0.2 mm or wider, ferric chloride etches copper quickly, often within 10-20 minutes at room temperature (around 25°C).

Disadvantages of Ferric Chloride

- Limited Precision: Ferric chloride tends to undercut the resist, meaning it etches sideways under the mask, which can result in less defined edges. This makes it less ideal as the best etchant for fine lines (below 0.1 mm).

- Non-Reusable: Once the solution is saturated with copper, its etching ability diminishes, and it cannot be easily regenerated.

- Environmental Concerns: The spent solution contains copper ions, which are toxic to aquatic life. It should never be poured down the drain and must be disposed of as hazardous waste.

- Staining and Mess: Ferric chloride can stain skin, clothing, and surfaces, requiring careful handling with gloves and protective gear.

What Is Cupric Chloride and How Does It Work for PCB Etching?

Cupric chloride, often used in cupric chloride PCB etching, is a green-colored solution that can be prepared by dissolving copper chloride crystals in water or by regenerating it through chemical processes. Its etching reaction with copper is as follows:

CuCl2 + Cu → 2CuCl

Here, cupric chloride (CuCl2) reacts with copper to form cuprous chloride (CuCl). Unlike ferric chloride, cupric chloride can be regenerated by bubbling air or adding hydrogen peroxide, which oxidizes CuCl back to CuCl2, making it reusable.

Advantages of Cupric Chloride for PCB Etching

- Precision: Cupric chloride provides better control over the etching process, with less undercutting compared to ferric chloride. This makes it a strong candidate for the best etchant for fine lines, achieving resolutions down to 0.05 mm or finer with proper setup.

- Reusability: The solution can be regenerated by adding hydrogen peroxide or exposing it to air, extending its lifespan and reducing waste. This is cost-effective for larger projects.

- Environmental Benefits: While still toxic due to copper content, the ability to reuse the solution reduces the volume of hazardous waste generated.

Disadvantages of Cupric Chloride

- Complexity: Preparing and maintaining a cupric chloride solution requires more knowledge and equipment, such as an air bubbler or peroxide dosing system for regeneration.

- Slower Etching: At room temperature, cupric chloride etches more slowly than ferric chloride, often taking 20-30 minutes for a standard board. Heating the solution to 40-50°C can speed up the process but requires caution.

- Availability: It’s less commonly available in ready-to-use form compared to ferric chloride, often requiring you to prepare it yourself from copper chloride crystals or by etching copper with hydrochloric acid and peroxide.

- Safety Risks: Cupric chloride is acidic and an oxidizer, posing risks of skin irritation and corrosion. Proper ventilation and protective gear are essential.

Etchant Comparison: Ferric Chloride vs. Cupric Chloride

Now that we’ve explored the basics of each etchant, let’s compare them head-to-head across key factors that matter to electrical engineers working on PCB fabrication. This etchant comparison will help you decide which of these PCB etching materials suits your needs.

1. Etching Speed

Ferric chloride typically etches faster at room temperature, completing a standard 1 oz copper board (35 μm thick) in about 10-20 minutes. Cupric chloride, on the other hand, can take 20-30 minutes under similar conditions unless heated. For rapid prototyping where time is critical, ferric chloride might be the better choice.

2. Precision and Fine Line Capability

For projects requiring high precision, such as dense circuits with trace widths below 0.1 mm, cupric chloride stands out as the best etchant for fine lines. Its slower, more controlled etching reduces undercutting, preserving the integrity of narrow traces. Ferric chloride, while adequate for wider traces (0.2 mm and above), often results in less sharp edges due to lateral etching under the resist.

3. Ease of Use

Ferric chloride wins in terms of simplicity. It’s a straightforward “mix and etch” solution, ideal for beginners or small-scale projects. Cupric chloride requires more effort to prepare and maintain, often involving additional steps like regeneration, which might deter hobbyists but appeal to professionals with access to proper lab equipment.

4. Cost and Reusability

Initially, ferric chloride is cheaper and more accessible, with a 500 mL bottle costing around $10-15. However, it’s a single-use solution—once saturated, it must be discarded. Cupric chloride, while potentially more expensive to set up (especially if buying chemicals like hydrochloric acid and hydrogen peroxide), can be reused multiple times, saving money in the long run for frequent etchers.

5. Safety and Environmental Impact

Both etchants contain copper in their waste, making them hazardous to the environment if not disposed of properly. Ferric chloride is notorious for staining and is harder to manage as waste due to its non-reusable nature. Cupric chloride, while also toxic, produces less waste volume over time due to regeneration, offering a slight environmental advantage. Always wear gloves, goggles, and work in a well-ventilated area with either chemical, and follow local regulations for hazardous waste disposal.

Practical Applications: Which Etchant Should You Choose?

Your choice of etchant depends on the specifics of your PCB project. Here are some scenarios to guide your decision:

- Hobbyist or One-Off Projects: If you’re a beginner or working on a single prototype with standard trace widths (0.2 mm or wider), ferric chloride is likely your best bet due to its affordability and ease of use. Just be prepared to handle the waste responsibly.

- Professional or High-Precision Work: For engineers designing complex boards with fine traces (below 0.1 mm) or high-density layouts, cupric chloride is the best etchant for fine lines. Its precision and reusability make it ideal for lab environments or repetitive production.

- Budget and Scale: If you etch frequently and want to minimize costs over time, invest in setting up a cupric chloride system. For occasional use, stick with ferric chloride to avoid the upfront hassle.

Tips for Safe and Effective PCB Etching

Regardless of which etchant you choose, following best practices ensures better results and safety:

- Prepare Your Workspace: Work in a well-ventilated area, preferably with a fume hood if using cupric chloride. Lay down plastic sheets or trays to catch spills, especially with ferric chloride’s staining potential.

- Use Proper PPE: Always wear nitrile gloves, safety goggles, and an apron to protect against chemical splashes. Avoid skin contact with either etchant.

- Control Temperature: For faster etching, warm your solution to 40-50°C, but never exceed 60°C as this can release toxic fumes. Use a non-metallic container and a thermometer to monitor temperature.

- Agitate the Solution: Gently agitate the etchant during the process (e.g., by rocking the container or using a small pump) to ensure even etching and prevent sediment buildup on the board.

- Dispose of Waste Properly: Never pour spent etchant down the drain. Store it in a labeled, sealed container and take it to a hazardous waste disposal facility. Check local regulations for guidance.

Conclusion: Making the Right Choice for Your PCB Fabrication

Choosing between ferric chloride PCB etching and cupric chloride PCB etching comes down to your project requirements, budget, and level of expertise. Ferric chloride offers a quick, accessible solution for hobbyists and simple designs, while cupric chloride excels as the best etchant for fine lines and professional-grade precision, with the added benefit of reusability.

ALLPCB

ALLPCB