Are you wondering how the color of a solder mask affects PCB manufacturing lead time and PCB fabrication costs? In short, the choice of solder mask color can influence both cost and production time, with standard colors like green often being the most economical and fastest to produce, while custom colors may increase expenses and extend timelines due to additional processing steps. In this comprehensive guide, we’ll dive deep into how solder mask cost varies with color choices, the impact on lead times, and what you need to know to make informed decisions for your next project.

What Is a Solder Mask and Why Does It Matter?

A solder mask is a thin protective layer applied to the copper traces of a printed circuit board (PCB). This layer, often made of a polymer material, shields the copper from oxidation, prevents solder bridges during assembly, and insulates the board to avoid electrical shorts. Beyond its functional role, the solder mask also gives the PCB its distinct color, which is why the choice of color can play a part in both aesthetics and manufacturing.

The color of the solder mask doesn’t change its primary protective qualities, but it can affect other aspects of PCB production, including PCB fabrication costs and PCB manufacturing lead time. Understanding these impacts is crucial for engineers and designers who aim to balance performance, budget, and delivery schedules.

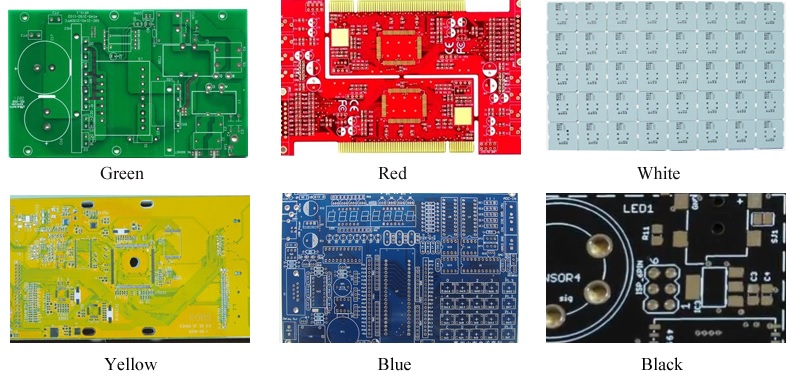

Standard Solder Mask Colors and Their Cost Implications

When it comes to solder mask cost, not all colors are created equal. The most common solder mask color is green, and there’s a good reason for that. Green solder mask is widely used because it’s the industry standard, offering a cost-effective solution due to its availability and optimized manufacturing processes.

Green Solder Mask Price: The Budget-Friendly Choice

The green solder mask price is typically the lowest among all options. Manufacturers keep large quantities of green solder mask material in stock, and their production lines are already set up for it. This means no additional setup costs or delays in sourcing materials. For small to medium-sized orders, choosing green can save anywhere from 5% to 10% on overall PCB fabrication costs compared to non-standard colors, depending on the volume and complexity of the board.

Additionally, green provides high contrast against copper traces and white silkscreen text, making visual inspections easier during quality control. This can indirectly reduce costs by minimizing errors and rework.

Other Standard Colors: Blue, Red, and Black

Besides green, other standard colors like blue, red, and black are also commonly available. These colors are slightly more expensive than green due to lower demand and occasional material sourcing adjustments. On average, opting for blue or red might increase solder mask cost by 10% to 20% compared to green. Black solder masks, often used for aesthetic purposes or to reduce light reflection in LED applications, can be even pricier due to the specific formulations required to achieve opacity and durability.

Custom Solder Mask Colors: Aesthetic Appeal at a Price

For projects where branding or visual appeal is a priority, custom solder mask colors can be an attractive option. Colors like yellow, white, purple, or even transparent masks are possible, but they come with a higher price tag and potential delays. Let’s break down why custom solder mask colors impact both cost and lead time.

Cost of Custom Solder Mask Colors

Choosing a non-standard color often requires manufacturers to order or mix specialized solder mask materials. This can add a significant surcharge to the production cost. For instance, custom solder mask colors can increase the PCB fabrication cost by 20% to 50% or more, depending on the color and the manufacturer’s capabilities. Small batch orders are particularly affected because the cost of custom materials isn’t spread across a large volume.

Additionally, custom colors may require extra testing to ensure they meet performance standards like adhesion and thermal resistance. These quality assurance steps can further drive up expenses.

Impact on PCB Manufacturing Lead Time

Lead time is another critical factor affected by custom solder mask colors. Since manufacturers may not stock these materials, sourcing them can add days or even weeks to the production schedule. For example, while a standard green solder mask PCB might take 5-7 days for production, a custom color could extend the PCB manufacturing lead time to 10-14 days or longer, especially if the material needs to be imported or specially formulated.

Moreover, applying custom colors might involve additional process adjustments or equipment calibration, further slowing down production. If your project is on a tight deadline, sticking with a standard color like green can help keep things on track.

How Solder Mask Color Affects Visual Inspection and Quality Control

Beyond direct costs and lead times, the choice of solder mask color can influence the quality control process, which indirectly impacts PCB fabrication costs. Colors like green and blue offer high contrast against copper traces and silkscreen markings, making it easier for technicians to spot defects such as misaligned components or solder bridges during manual or automated optical inspections.

On the other hand, lighter colors like yellow or white, or even darker shades like black, can reduce visibility of traces and markings. This might lead to longer inspection times or a higher risk of missed defects, potentially increasing rework costs or delaying delivery. While this doesn’t directly tie to solder mask cost, it’s an important consideration for overall project efficiency.

Balancing Aesthetics, Cost, and Lead Time in Solder Mask Selection

Choosing the right solder mask color involves weighing several factors: aesthetics, budget, and timeline. Here are some practical tips to help you make the best decision for your PCB project:

- Stick with Standard Colors for Tight Budgets: If minimizing PCB fabrication costs is your priority, go with green or another widely available color like blue. The green solder mask price advantage makes it ideal for cost-sensitive projects.

- Plan Ahead for Custom Colors: If branding requires custom solder mask colors, account for both the higher cost and extended PCB manufacturing lead time. Communicate with your manufacturer early to understand their capabilities and timelines.

- Consider Inspection Needs: For complex designs where visual inspection is critical, opt for high-contrast colors to streamline quality control and avoid costly rework.

- Volume Matters: For large production runs, the per-unit cost difference between standard and custom colors becomes less significant. However, for prototypes or small batches, the surcharge for custom options can be substantial.

Technical Considerations: Does Color Affect Performance?

While the focus of this article is on solder mask cost and PCB manufacturing lead time, it’s worth addressing whether color impacts the technical performance of the PCB. In most cases, the answer is no. The protective properties of the solder mask—such as resistance to heat, moisture, and chemicals—are determined by the material composition, not the pigment used for coloring.

However, there are exceptions. For instance, black solder masks are sometimes used in applications where light absorption is needed, such as LED boards, to prevent unwanted reflections. White masks might be chosen for reflective purposes in specific lighting designs. These functional choices can indirectly influence costs if specialized materials are required to achieve the desired effect.

Industry Trends in Solder Mask Colors

Over the years, the PCB industry has seen shifts in solder mask color preferences. While green remains the dominant choice due to its low green solder mask price and ease of use, there’s a growing trend toward customization as companies seek to differentiate their products visually. Custom colors are becoming more accessible as manufacturers expand their offerings, though the cost and lead time implications remain a barrier for many.

Additionally, advancements in solder mask materials are making it easier to achieve consistent results with non-standard colors, potentially reducing the solder mask cost premium over time. Staying updated on these trends can help you make smarter choices for future projects.

How to Work with Your Manufacturer on Solder Mask Choices

To ensure your solder mask color choice aligns with your budget and timeline, clear communication with your PCB manufacturer is essential. Here’s how to approach the process:

- Specify Your Requirements Early: Clearly state your preferred color during the design phase to avoid last-minute changes that could delay production.

- Request Cost and Lead Time Estimates: Ask for detailed quotes that break down the solder mask cost and expected PCB manufacturing lead time for different color options.

- Understand Limitations: Not all manufacturers support every color or custom option. Confirm their capabilities before finalizing your design.

- Test Custom Colors if Needed: For critical applications, request samples or prototypes with your chosen color to verify performance and appearance before full production.

Conclusion: Making an Informed Choice for Your PCB Project

The color of your PCB’s solder mask might seem like a small detail, but it can have a noticeable impact on PCB fabrication costs and PCB manufacturing lead time. Standard options like green offer the lowest green solder mask price and fastest turnaround, making them ideal for most projects. On the other hand, custom solder mask colors provide unique branding opportunities but come with higher costs and potential delays.

By understanding the trade-offs and planning accordingly, you can select a solder mask color that meets your technical, aesthetic, and budgetary needs. Whether you’re optimizing for cost with a standard color or investing in a custom look for a premium product, the key is to align your choice with your project goals and communicate effectively with your manufacturer.

ALLPCB

ALLPCB