Designing a security camera PCB for low-light conditions is a critical task for ensuring reliable surveillance in dim or nighttime environments. Whether you're working on a CCTV system or a night vision camera, the performance in low-light settings depends heavily on careful component selection and smart PCB layout techniques. In this comprehensive guide, we'll dive into optimizing security camera PCB low light performance, focusing on image sensor selection for CCTV, PCB layout for night vision cameras, noise reduction in security camera PCBs, and IR illuminator PCB design. Let’s explore how to build a high-performing security camera system that excels when the lights go out.

Why Low-Light Performance Matters in Security Camera PCBs

Security cameras are often needed most in low-light or complete darkness, such as during nighttime surveillance or in poorly lit areas. A poorly designed PCB can result in grainy images, high noise levels, or complete failure to capture usable footage. Optimizing a security camera PCB for low-light conditions ensures clearer images, better detection, and enhanced safety. By focusing on the right components and layout strategies, you can significantly improve performance without inflating costs.

Key Factors in Security Camera PCB Design for Low-Light Conditions

Before diving into specific techniques, let’s outline the core factors that impact security camera PCB low light performance. These include the choice of image sensor, noise management, power supply stability, and integration of infrared (IR) illumination. Each element must work together to ensure the camera captures usable footage in challenging lighting.

1. Image Sensor Selection for CCTV: The Heart of Low-Light Performance

The image sensor is the most critical component for low-light performance in a security camera. It converts light into an electrical signal, and its sensitivity directly affects image quality in dim conditions. When focusing on image sensor selection for CCTV, consider the following:

- Sensor Type: CMOS sensors are widely used in modern security cameras due to their lower power consumption and better performance in low light compared to older CCD sensors. Look for back-illuminated (BSI) CMOS sensors, which have improved light sensitivity by placing the wiring behind the photodiodes.

- Pixel Size: Larger pixels capture more light, improving performance in dim environments. For example, a sensor with 2.8 μm pixel size will generally outperform one with 1.4 μm in low-light settings.

- Dynamic Range: A high dynamic range (HDR) capability, often above 100 dB, helps the sensor handle varying light levels, preventing overexposure or underexposure in mixed lighting.

- Low-Light Sensitivity: Look for sensors with a high signal-to-noise ratio (SNR). Some sensors are rated for sensitivity down to 0.001 lux, making them ideal for night vision applications.

Choosing a sensor with these characteristics ensures that your security camera can detect even faint light sources, providing clearer images during nighttime surveillance.

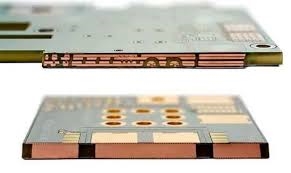

2. PCB Layout for Night Vision Cameras: Minimizing Interference

The PCB layout for night vision cameras plays a pivotal role in maintaining signal integrity and reducing noise, both of which are crucial for low-light performance. A poorly designed layout can introduce interference that degrades image quality. Follow these layout techniques to optimize your design:

- Separate Analog and Digital Grounds: Image sensors and related analog circuits are highly sensitive to noise from digital components. Use separate ground planes for analog and digital sections, connecting them at a single point near the power supply to minimize ground loops.

- Short Signal Paths: Keep the traces between the image sensor and the processing unit as short as possible to reduce signal loss and electromagnetic interference (EMI). For high-speed signals, aim for trace lengths under 10 mm if feasible.

- Shield Sensitive Components: Place a ground plane or shielding around the image sensor to protect it from external EMI. This is especially important in cameras with integrated IR illuminators, which can generate additional interference.

- Component Placement: Position the image sensor away from high-current components like power regulators or IR LEDs to avoid thermal noise. Maintain at least 5 mm of clearance between heat-generating parts and sensitive areas.

A well-thought-out PCB layout ensures that the delicate signals from the image sensor remain clean, directly improving low-light image quality.

3. Noise Reduction in Security Camera PCBs: Ensuring Clear Images

Noise is the enemy of low-light performance, as it can obscure details in already dim conditions. Effective noise reduction in security camera PCBs involves both component selection and design strategies. Here’s how to tackle noise:

- Low-Noise Power Supply: Use low-dropout (LDO) regulators with a noise level below 10 μV RMS to power the image sensor. Switching regulators, while efficient, often introduce ripple noise that can degrade image quality.

- Decoupling Capacitors: Place 0.1 μF and 1 μF ceramic capacitors close to the power pins of the image sensor to filter out high-frequency noise. Ensure these capacitors are within 2 mm of the pins for maximum effectiveness.

- Signal Filtering: Incorporate low-pass filters on analog signal lines to remove high-frequency noise before it reaches the processing unit. A cutoff frequency of around 10 MHz is often suitable for video signals.

- Thermal Noise Management: Keep the PCB operating temperature low, as heat increases thermal noise in the sensor. Use heat sinks or thermal vias if high-power components are nearby.

By implementing these noise reduction techniques, you can ensure that the camera’s output remains clear even when light levels are minimal.

4. IR Illuminator PCB Design: Enhancing Night Vision

Infrared (IR) illuminators are essential for night vision cameras, providing invisible light that the sensor can detect without alerting intruders. Proper IR illuminator PCB design ensures effective illumination while avoiding interference with other components. Consider these tips:

- IR LED Selection: Choose IR LEDs with a wavelength between 850 nm and 940 nm. The 850 nm range offers better illumination but may emit a faint red glow, while 940 nm is completely invisible to the human eye, ideal for covert surveillance.

- Current and Heat Management: IR LEDs often require high currents (up to 1 A per LED). Use a constant current driver to prevent overdriving, and include thermal vias or heat sinks to dissipate heat, as excessive temperatures can reduce LED lifespan.

- Placement and Spacing: Arrange IR LEDs in a circular pattern around the camera lens to provide even illumination. Ensure a minimum spacing of 3 mm between LEDs to avoid thermal overlap and interference with the sensor.

- Power Isolation: Isolate the IR illuminator power circuit from the image sensor’s power supply to prevent voltage spikes or noise from affecting image quality. Use separate power traces or a dedicated regulator for the IR circuit.

A well-designed IR illuminator circuit extends the camera’s effective range in complete darkness, often up to 30 meters or more, depending on the LED power and lens design.

Additional Tips for Optimizing Security Camera PCB Design

Beyond the core areas discussed, here are a few additional considerations to further enhance security camera PCB low light performance:

- Firmware Optimization: Work with firmware engineers to implement digital noise reduction algorithms and automatic gain control (AGC) to boost low-light performance without hardware changes.

- Testing in Real Conditions: Simulate low-light environments during testing, using light levels as low as 0.01 lux, to ensure the camera performs as expected in real-world scenarios.

- Material Selection: Use high-quality PCB materials with low dielectric loss (e.g., FR-4 with a dielectric constant of 4.5 or lower) to maintain signal integrity for high-frequency video signals.

Challenges and Solutions in Low-Light PCB Design

Designing for low-light conditions isn’t without challenges. One common issue is balancing power consumption with performance, as high-sensitivity sensors and IR illuminators can drain batteries quickly. A solution is to use power-efficient components and implement sleep modes in the firmware to reduce consumption when the camera isn’t actively recording.

Another challenge is managing heat from IR LEDs and power circuits, which can degrade sensor performance. Address this by incorporating thermal vias and ensuring adequate spacing between heat sources and sensitive components, as mentioned earlier.

Conclusion: Building Better Security Cameras for Low-Light Environments

Creating a security camera that excels in low-light conditions requires a thoughtful approach to PCB design. By prioritizing image sensor selection for CCTV, optimizing PCB layout for night vision cameras, focusing on noise reduction in security camera PCBs, and perfecting IR illuminator PCB design, you can ensure exceptional security camera PCB low light performance. Each component and layout decision plays a vital role in capturing clear, reliable footage when it matters most.

At ALLPCB, we’re committed to supporting engineers in designing high-quality security camera systems. With the right strategies and manufacturing support, you can build surveillance solutions that stand out in any lighting condition. Start applying these techniques in your next project to see the difference in performance and reliability.

ALLPCB

ALLPCB