In the world of electronics manufacturing, solder paste plays a crucial role in ensuring the reliability and performance of printed circuit boards (PCBs). Specifically, SMT solder paste and lead-free solder paste are vital components in surface mount technology (SMT), which is the backbone of modern electronics assembly. The precise application of solder paste aligned over the PCB directly impacts the quality of connections, the durability of the final product, and overall manufacturing efficiency. In this blog, we'll dive deep into why solder paste is so important, how it works, and best practices for its application in electronics production.

What Is Solder Paste and Why Does It Matter?

Solder paste is a mixture of tiny metal solder particles suspended in a flux medium. This sticky substance acts as both an adhesive and a conductor during the assembly process. It holds electronic components in place on a PCB before they are permanently bonded through a heating process called reflow soldering. Without solder paste, creating reliable electrical and mechanical connections in SMT would be nearly impossible.

The importance of solder paste in electronics cannot be overstated. It ensures that components are securely attached to the PCB while forming strong electrical connections. Poor quality or improperly applied solder paste can lead to defects like bridging (short circuits), insufficient solder joints, or incomplete connections, which can cause device failure. With the rise of smaller, more complex devices, the precision of solder paste application has become even more critical.

The Role of SMT Solder Paste in Electronics Manufacturing

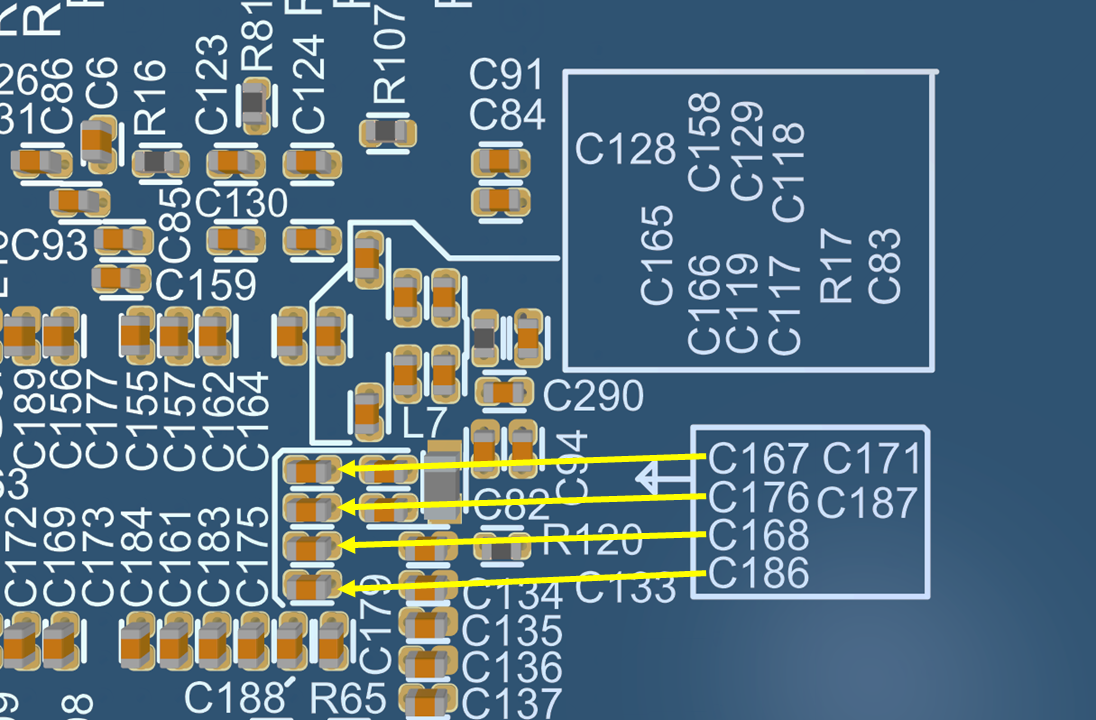

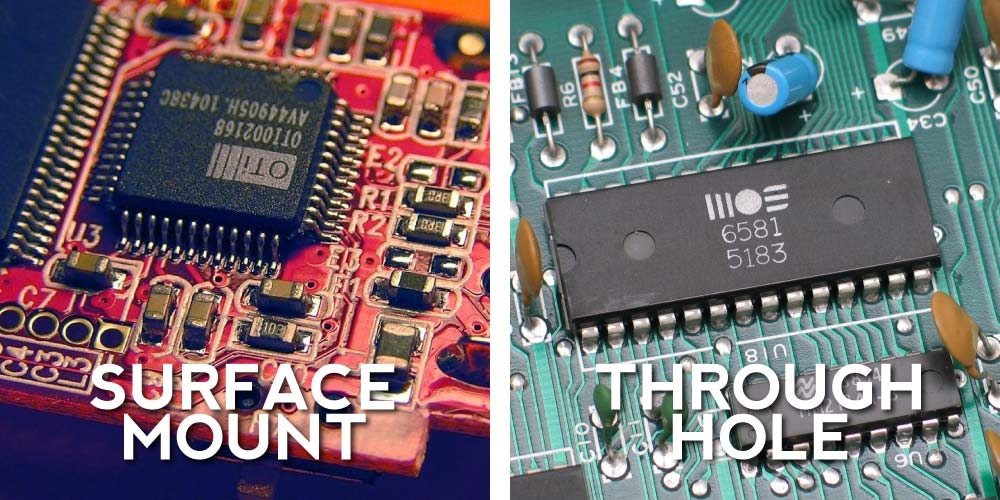

SMT solder paste is specifically designed for surface mount technology, the most widely used method for assembling modern electronics. Unlike traditional through-hole technology, SMT involves placing components directly onto the surface of the PCB. SMT solder paste is applied to the board using a stencil, ensuring that the paste is deposited only on the designated pads where components will be placed.

The composition of SMT solder paste typically includes a powdered alloy (often a mix of tin, silver, and copper for lead-free options) and flux, which cleans the surfaces during soldering to ensure a strong bond. The paste must have the right viscosity to adhere to the board without spreading too much or drying out before reflow. According to industry standards, defects in solder paste printing account for up to 60% of SMT assembly failures, highlighting the need for precision and quality in this step.

SMT solder paste comes in different types, such as Type 3, Type 4, and Type 5, which refer to the size of the solder particles. For instance, Type 4 and Type 5 pastes, with smaller particle sizes, are ideal for fine-pitch components and high-density PCBs where precision is critical. Choosing the right type of paste can significantly boost PCB performance by reducing defects and improving connection reliability.

Lead-Free Solder Paste: A Sustainable and Safe Choice

With growing environmental and health concerns, the electronics industry has shifted toward lead-free solder paste. Traditional solder paste often contained lead, which posed risks to both human health and the environment. In response, regulations like the Restriction of Hazardous Substances (RoHS) directive have pushed manufacturers to adopt lead-free alternatives.

Lead-free solder paste typically consists of alloys like tin-silver-copper (SAC) or tin-copper. While these materials have a higher melting point (around 217-220°C compared to 183°C for lead-based solder), they offer comparable performance when applied correctly. The transition to lead-free solder paste has also introduced challenges, such as the increased risk of defects like "head-in-pillow," where the solder joint appears connected but lacks proper fusion. However, advancements in flux formulations and reflow profiles have helped mitigate these issues.

Using lead-free solder paste not only ensures compliance with global regulations but also appeals to environmentally conscious consumers. It’s a key factor in modern electronics manufacturing, balancing safety, sustainability, and performance.

Application of Solder Paste: Precision Alignment Over the PCB

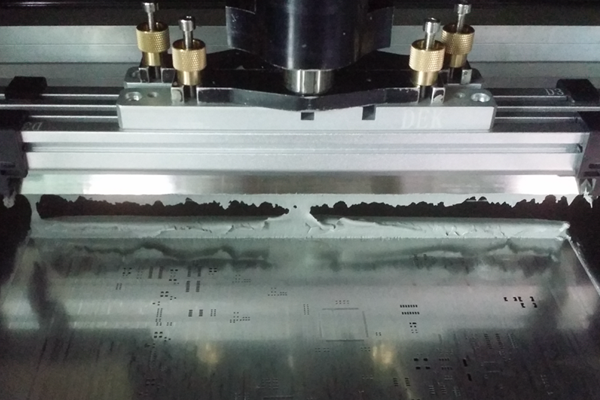

The application of solder paste aligned precisely over the PCB is a critical step in electronics assembly. This process typically involves using a stencil printer to deposit the paste onto specific areas of the board. The stencil, a thin metal sheet with cutouts corresponding to the PCB pads, ensures that the paste is applied only where it’s needed. Misalignment or uneven application can lead to defects, such as insufficient solder or bridging between pads, resulting in short circuits.

To achieve precise alignment, manufacturers rely on automated stencil printers equipped with vision systems. These machines use cameras to align the stencil with the PCB, ensuring accuracy down to micrometers. For high-volume production, maintaining a consistent stencil-to-board gap (often around 0.1 to 0.2 mm) and controlling the squeegee pressure (typically 8-12 kg for standard applications) are essential for uniform paste deposition.

After application, the PCB undergoes a pick-and-place process where components are positioned onto the solder paste. The sticky nature of the paste holds the components in place until the board is heated in a reflow oven. During reflow, the solder particles melt and form a solid joint, while the flux evaporates or is cleaned off. Precision in solder paste application directly affects the success of this process, making it a cornerstone of reliable PCB assembly.

Common Challenges in Solder Paste Application and How to Overcome Them

While solder paste is indispensable, its application comes with several challenges that can impact the quality of the final product. Here are some common issues and practical solutions:

- Insufficient Paste Deposition: This occurs when too little paste is applied, leading to weak or incomplete solder joints. It can be caused by worn-out stencils or incorrect printer settings. Solution: Regularly inspect and replace stencils, and calibrate printer parameters like squeegee speed (typically 20-40 mm/s) and pressure.

- Bridging: Excess paste or misalignment can cause solder to connect adjacent pads, creating short circuits. Solution: Use a finer mesh stencil for high-density boards and ensure precise alignment with vision systems.

- Paste Drying Out: Solder paste can lose its tackiness if exposed to air for too long, affecting component placement. Solution: Store paste in a temperature-controlled environment (2-10°C) and follow manufacturer guidelines for shelf life and usage time (often 4-6 hours at room temperature).

- Head-in-Pillow Defects: Common with lead-free solder paste, this defect happens when the solder ball and paste don’t fully coalesce. Solution: Optimize the reflow temperature profile, ensuring a peak temperature of 235-245°C for SAC alloys, and use pastes with advanced flux formulations.

By addressing these challenges, manufacturers can improve yield rates and reduce costly rework, ensuring that the application of solder paste contributes to a high-quality end product.

Best Practices for Using Solder Paste in SMT Assembly

To maximize the effectiveness of SMT solder paste and lead-free solder paste, follow these best practices during application and handling:

- Choose the Right Paste Type: Select a solder paste based on the component size and PCB design. For fine-pitch applications (below 0.5 mm), use Type 4 or Type 5 paste for better precision.

- Control Storage Conditions: Store solder paste in a refrigerator at 2-10°C to maintain its properties. Before use, allow it to reach room temperature (around 25°C) for 4-6 hours to avoid condensation, which can affect performance.

- Optimize Stencil Design: Ensure the stencil thickness (typically 0.1-0.15 mm for standard SMT) and aperture size match the PCB pad layout to achieve uniform paste deposition.

- Monitor Reflow Profiles: Adjust the reflow oven settings based on the solder paste type. For lead-free solder paste, maintain a gradual ramp-up rate (1-3°C per second) to prevent thermal shock to components.

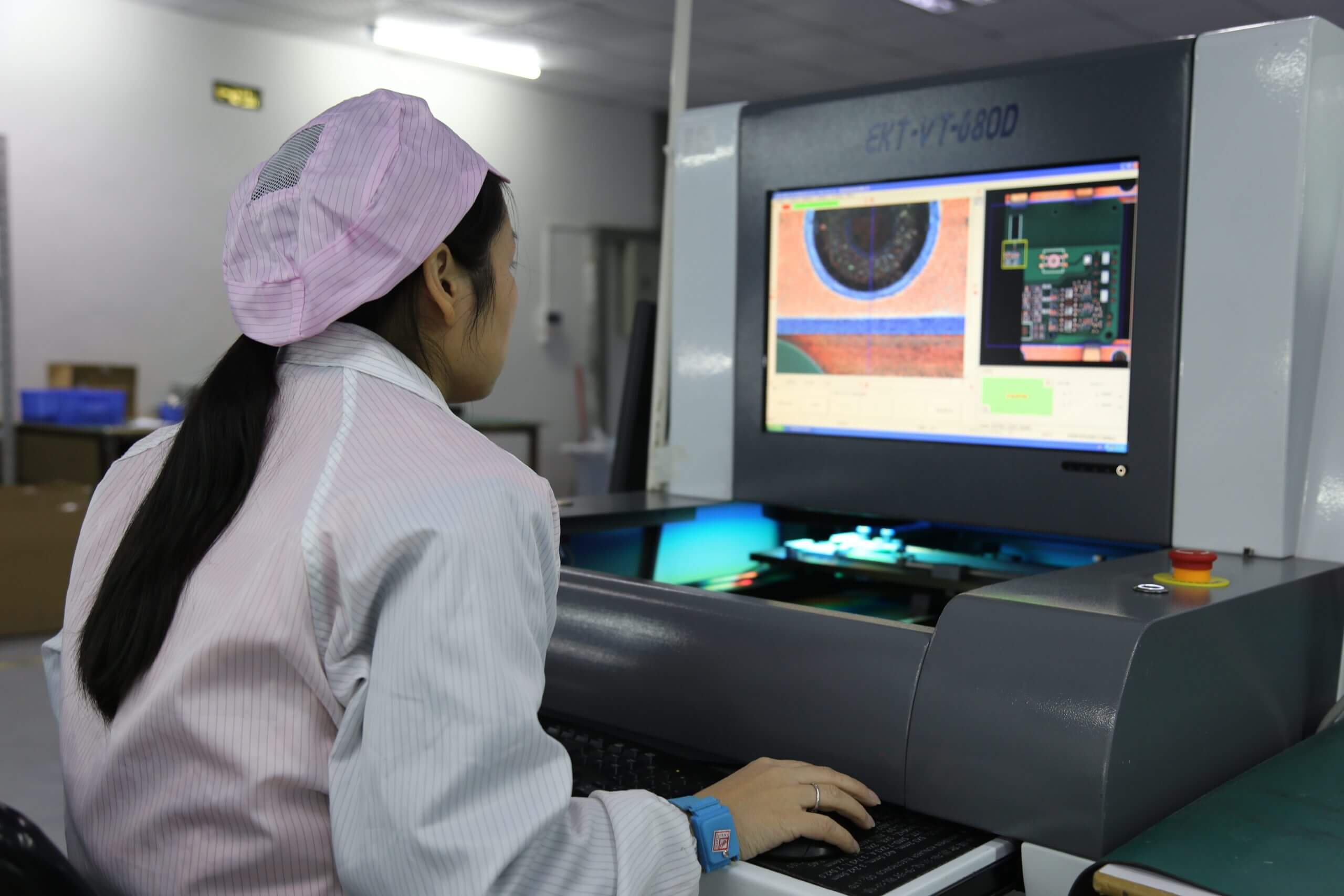

- Perform Regular Inspections: Use automated optical inspection (AOI) systems to check for defects like misalignment or insufficient paste after printing. Early detection can save time and reduce waste.

Adhering to these practices ensures that the solder paste performs as intended, resulting in reliable and durable electronic assemblies.

The Future of Solder Paste in Electronics

As electronics continue to shrink in size and grow in complexity, the role of solder paste will only become more critical. Innovations in solder paste formulations are already addressing challenges like higher reflow temperatures for lead-free options and the need for finer particle sizes for ultra-small components. Additionally, advancements in stencil printing technology, such as nano-coated stencils and 3D printing techniques, are improving the precision of solder paste application.

The push for sustainability is also shaping the future of solder paste. Researchers are exploring new alloys and flux materials that reduce energy consumption during reflow and minimize waste. These developments will ensure that solder paste remains a key factor in electronics manufacturing, supporting the creation of smarter, more efficient devices.

Conclusion

Solder paste is undeniably a key factor in electronics, serving as the foundation for reliable and high-performing PCB assemblies. Whether it's SMT solder paste for surface mount technology or lead-free solder paste for eco-friendly production, its precise application aligned over the PCB determines the success of the manufacturing process. By understanding its composition, addressing common challenges, and following best practices, manufacturers can achieve consistent quality and reduce defects.

At every stage of electronics production, from stencil printing to reflow soldering, solder paste plays a pivotal role in connecting components and ensuring functionality. As technology evolves, so too will the materials and methods surrounding solder paste, keeping it at the heart of innovation in the electronics industry. By prioritizing precision and quality in solder paste application, we can build a future of more reliable and sustainable electronic devices.

ALLPCB

ALLPCB