1. Why devices are frequently repaired

Lack of ESD (electrostatic discharge) protection can harm electronic devices and components. Common consequences include:

- Component damage: ESD can permanently damage or destroy electronic components, causing device failures or requiring component replacement.

- Data loss: ESD events that affect storage media (for example, hard drives or flash drives) can corrupt or erase data, leading to lost or inaccessible information.

- Intermittent failures: ESD can cause temporary malfunctions or crashes, increasing downtime, repair costs, and reducing production efficiency.

- Reduced product quality: Without proper ESD control during manufacturing or assembly, devices may develop defects that affect reliability and performance.

- Higher costs: Repairing or replacing ESD-damaged components consumes time and resources; lack of ESD protection can also require extra quality control and testing, raising manufacturing costs.

Appropriate ESD protection includes using antistatic tools and grounding measures, suitable work surfaces and floor materials, and proper packaging and storage.

2. Structural protection

- Design to avoid gaps: Preventing gaps in enclosures reduces the risk of air discharge breakdown. If gaps are unavoidable, minimize their size.

- Choose compatible enclosure materials: Use a single material for the housing when possible, and ensure overlap between top and bottom covers. If manufacturing allows, apply gasketing or sealant.

- Route sensitive circuits away from gaps: Keep harnesses and sensitive components away from enclosure openings or seams.

3. Circuit-level ESD protection

On schematics, ESD protection focuses on controlling conducted transients. The main approaches are shunting the transient to ground and blocking its propagation.

Shunting provides a low-impedance path to ground to divert transient energy. Typical components used for shunting are capacitors, TVS diodes, and varistors.

Blocking uses resistance to limit the transient current. Resistors that are too small have little effect; resistors that are too large can degrade signal integrity. Thus, resistance is generally a supplementary measure.

3.1 Capacitors

Capacitors are a common first choice for ESD suppression because they provide a low-impedance path for high-frequency transients and can attenuate interference. They are suitable for many low- to moderate-speed signal lines, but they are not appropriate for high-speed signals and may be ineffective for very large surge events. Capacitors may help for smaller kV-level ESD events, but their effectiveness depends on the transient characteristics and placement.

3.2 TVS diodes

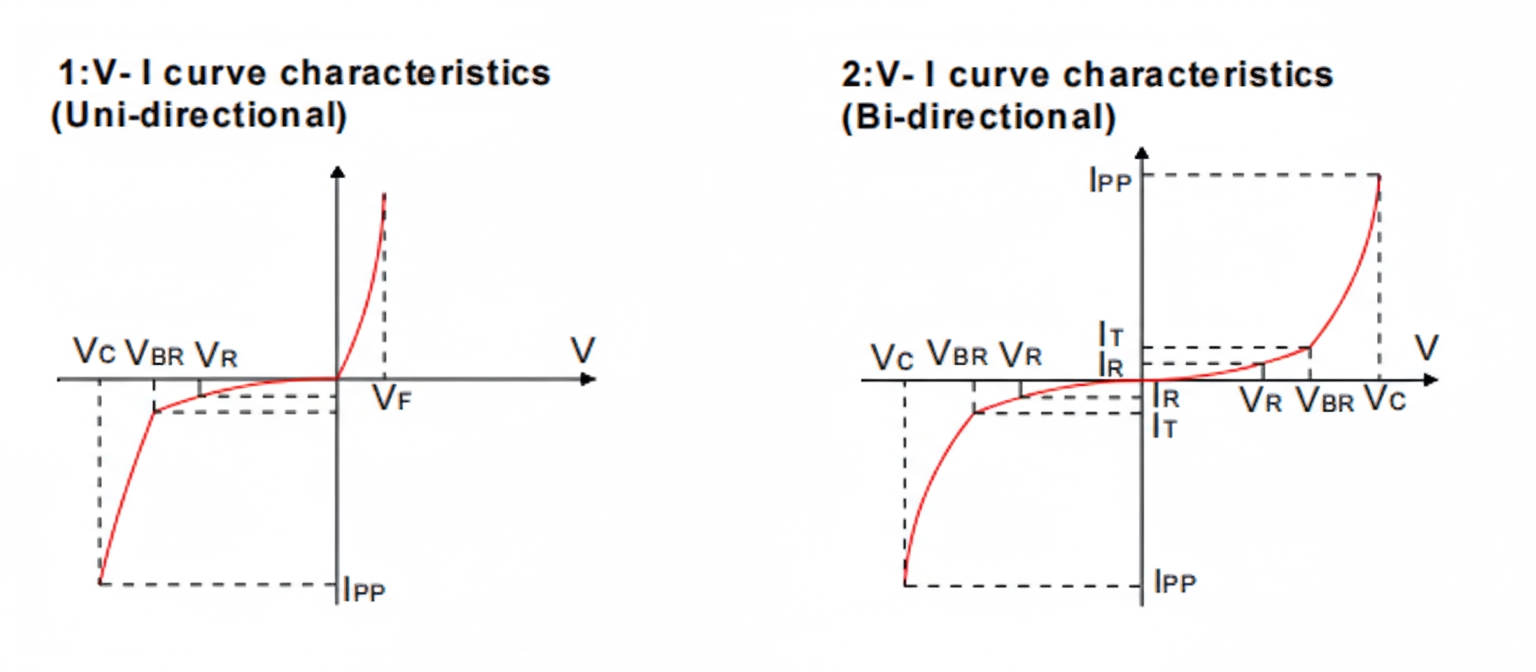

TVS (transient voltage suppression) diodes are devices designed to clamp voltage transients. Under a high-energy, short-duration pulse, a TVS diode switches from high impedance to low impedance in nanoseconds, conducting the surge current and clamping the voltage to a safe level to protect downstream components. Key parameters include standoff voltage, breakdown voltage, peak pulse current, and forward conduction voltage. TVS diodes are widely used because of their fast response, high surge handling capability, low leakage, and ability to clamp repeated transients.

3.3 Metal oxide varistors (MOVs)

Metal oxide varistors use a zinc oxide (ZnO) ceramic to clamp overvoltage. Below their threshold voltage, they exhibit very high resistance; above the threshold, their resistance drops rapidly, allowing surge energy to be diverted. MOVs absorb energy physically and degrade with each surge, so their lifespan is finite and determined by the number and severity of transient events. Typical response times are in the microsecond range, slower than TVS diodes, and they are commonly used where slower but economical surge protection is acceptable.

ALLPCB

ALLPCB