Overview

Filter capacitors, common-mode chokes, and ferrite beads are common components in EMC circuit design and are widely used to mitigate electromagnetic interference.

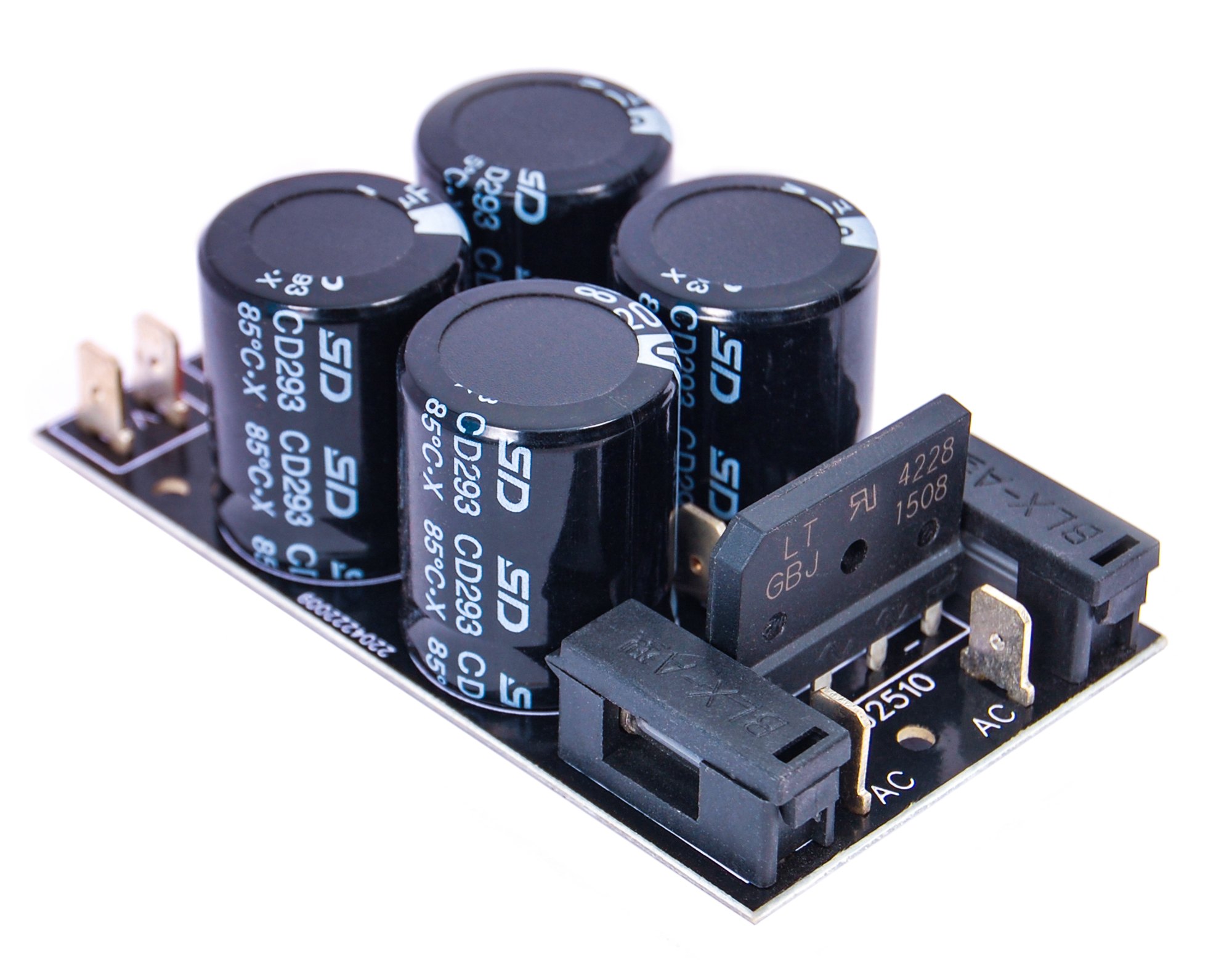

Filter Capacitors

Although capacitor resonance is generally undesirable when removing high-frequency noise, resonance is not always harmful. If the noise frequency to be filtered is known, the capacitor value can be tuned so that the resonance falls at the interference frequency.

In practice, electromagnetic noise to be suppressed often extends into the hundreds of MHz or above 1 GHz. To effectively filter such high-frequency noise, feedthrough capacitors are required.

Ordinary capacitors fail to filter high-frequency noise effectively for two reasons:

- Lead inductance of the capacitor causes resonance, presenting high impedance to high-frequency signals and reducing the bypass effect.

- Parasitic capacitance between conductors enables coupling of high-frequency signals, degrading filtering performance.

Feedthrough capacitors are effective because they avoid the lead inductance that lowers the resonance frequency. They can be mounted directly to a metal panel, using the panel to provide high-frequency isolation. However, attention must be paid to mounting.

The main weakness of feedthrough capacitors is their sensitivity to high temperature and thermal shock, which makes soldering them to metal panels challenging. Many capacitors are damaged during soldering. When many feedthrough capacitors are mounted on a panel, a single damaged part can be difficult to replace because removing it may damage adjacent components.

Common-Mode Chokes

Because many EMC issues involve common-mode interference, common-mode chokes are commonly used suppression components.

A common-mode choke is a ferrite-core device formed by symmetrically winding two coils with identical dimensions and turns on the same toroidal core, creating a four-terminal component. It presents high inductance to common-mode signals, which suppresses them, while it exhibits very low leakage inductance to differential-mode signals and thus has little effect on them.

The principle is that for common-mode currents, the magnetic fluxes in the core add, producing a large inductance that suppresses common-mode current. For differential-mode currents, the fluxes cancel out, so there is almost no inductance and differential signals pass with little attenuation. Therefore, common-mode chokes effectively suppress common-mode interference on balanced lines while leaving normal differential-mode transmission unaffected.

When manufacturing common-mode chokes, the following requirements should be met:

- Wires wound on the core must be insulated from each other to prevent inter-turn breakdown under transient overvoltage.

- The core must not saturate under transient high currents.

- The core should be insulated from the windings to prevent breakdown between them under transient overvoltage.

- Windings should be single-layer where possible to reduce parasitic capacitance and improve withstand capability for transient overvoltages.

In normal practice, choose a choke whose common-mode impedance is as large as possible in the target filter band. Selection is normally based on the impedance-versus-frequency characteristic provided in the device datasheet. Also consider differential-mode impedance and its impact on signals, especially for high-speed ports.

Ferrite Beads

Ferrite beads are commonly used in EMC design for digital circuits, power lines, and data lines. Ferrite materials are typically iron-magnesium or iron-nickel based compositions with high permeability. They are effective at presenting high impedance at high frequency while minimizing parasitic capacitance between coil turns.

Ferrite materials are generally applied at high frequency: at low frequency they behave mainly as inductance with low loss, while at high frequency they exhibit resistive characteristics that vary with frequency. In practice, ferrites are used as high-frequency attenuators in RF circuits.

Ferrites can be modeled as a resistor in parallel with an inductor: at low frequency the resistor is shorted by the inductor, while at high frequency the inductive reactance becomes large so current flows through the resistive branch. Ferrite components dissipate high-frequency energy as heat because of their resistive behavior. Compared with ordinary inductors, ferrite beads offer better high-frequency filtering performance.

At high frequency a ferrite appears resistive, equivalent to an inductor with a very low quality factor, so it maintains a relatively high impedance over a wide frequency range and improves high-frequency filtering effectiveness.

In the low-frequency band, impedance is dominated by inductive reactance: R is small, the core permeability is high, and L dominates. The device behaves as a low-loss, high-Q inductor, which can produce resonance; in some cases this can increase interference after using a ferrite bead. In the high-frequency band, impedance is dominated by resistive components: as frequency rises, core permeability decreases and inductance decreases, reducing reactance. At the same time, core losses increase and the resistive component rises, increasing total impedance. High-frequency signals are absorbed by the ferrite and dissipated as heat.

Ferrite suppression components are widely used on printed circuit boards, power lines, and data lines. For example, placing a ferrite suppression component at the power line entry on a PCB can filter high-frequency interference. Ferrite rings or beads are used to suppress high-frequency and spike interference on signal and power lines, and they can absorb electrostatic discharge pulses. The choice between a chip ferrite bead and a chip inductor depends on the application.

Chip Inductors vs Chip Ferrite Beads

Chip inductors: Used in RF and wireless communications, information technology equipment, radar detectors, automotive electronics, cellular phones, pagers, audio equipment, PDAs, wireless remote systems, and low-voltage power modules.

Chip ferrite beads: Used for clock circuits, filtering between analog and digital circuits, I/O connector lines (for example serial ports, parallel ports, keyboards, mice, long-distance telecom, local area networks), between RF circuits and sensitive logic devices, for removing high-frequency conducted noise in power circuits, and for EMI suppression in computers, printers, VCRs, TVs, and mobile phones.

Ferrite bead impedance is specified in ohms because it is named by the impedance it presents at a given frequency. Datasheets typically provide frequency-versus-impedance curves, commonly referenced at 100 MHz. For example, a bead rated at 1000 ohms at 100 MHz has that impedance at 100 MHz.

Select ferrite beads so that impedance is as large as possible in the target frequency band; commonly a bead with impedance above 600 ohms is chosen. Also check the bead's current rating: apply a derating factor, typically around 80%. When used in power circuits, consider the DC resistance and its impact on voltage drop.

ALLPCB

ALLPCB