Are you a hobbyist looking to level up your skills in PCB rework, or a professional seeking the perfect tools to streamline your workflow? Whether you're searching for a beginner rework station, an affordable rework station for hobbyists, or tips on DIY PCB rework, choosing the right equipment is the key to success. In this comprehensive guide, we'll walk you through everything you need to know about mastering PCB rework, from selecting a rework station for small components to using a soldering rework station effectively. Let’s dive into the world of PCB rework and help you transition from hobbyist to pro with confidence.

What Is PCB Rework and Why Does It Matter?

PCB rework refers to the process of repairing or modifying a printed circuit board after it has been assembled. This could involve replacing faulty components, fixing broken traces, or desoldering and resoldering parts to correct errors. For hobbyists and professionals alike, rework is a critical skill because mistakes happen—whether it's a misplaced component or a soldering joint that didn’t hold. Mastering PCB rework saves time, reduces waste, and ensures your projects meet high standards.

Rework is especially important when dealing with small, delicate components on modern circuit boards. Without the right tools, such as a reliable rework station for small components, you risk damaging the board or surrounding parts. In this guide, we’ll explore how the right equipment can make all the difference in achieving professional results.

Understanding the Basics: Rework Station vs. Soldering Station

Before diving into specific recommendations, it’s important to understand the difference between a rework station and a soldering station. A soldering station typically includes a soldering iron and is used for joining components to a PCB. A rework station, on the other hand, often combines a soldering iron with a hot air tool, making it ideal for both soldering and desoldering tasks. This dual functionality is especially useful for DIY PCB rework, where you may need to remove and replace components frequently.

For beginners, a beginner rework station with basic features is often enough to get started. As you grow in skill, you might look for more advanced options with precise temperature control and additional accessories. Let’s break down what to look for in a rework station to match your needs.

Key Features to Look for in a Rework Station

Choosing the right rework station can feel overwhelming with so many options available. Here are the essential features to consider, whether you're a hobbyist or a seasoned pro:

1. Temperature Control and Stability

Temperature control is critical when working on PCBs, especially with small or heat-sensitive components. A good rework station should offer adjustable temperature settings, ideally ranging from 100°C to 480°C for hot air tools and 200°C to 450°C for soldering irons. Look for stations with digital displays for precise control—some models even maintain temperature stability within ±2°C, ensuring consistent performance.

2. Hot Air and Soldering Capabilities

For versatility, opt for a two-in-one soldering rework station that includes both a hot air gun and a soldering iron. The hot air tool is perfect for desoldering surface-mount components (SMDs), while the soldering iron handles through-hole components and precise soldering tasks. This combination is especially useful for rework stations for small components, as it allows you to tackle a wide range of repairs.

3. Airflow Control for Hot Air Tools

When using hot air for desoldering, adjustable airflow is essential to avoid damaging nearby components. Look for a station with airflow settings between 20 to 120 liters per minute, giving you the flexibility to work on delicate parts without overheating the board.

4. Ergonomic Design and Ease of Use

For hobbyists, an affordable rework station for hobbyists should be user-friendly. Lightweight tools, comfortable grips, and intuitive controls make long rework sessions less tiring. Some stations also come with built-in stands or holders for the hot air gun and soldering iron, keeping your workspace organized.

5. Price and Budget

Budget is a major factor, especially for beginners. Luckily, there are many affordable rework stations for hobbyists priced between $50 and $100 that offer decent performance for basic tasks. As you advance, investing in a higher-end model with more features can improve efficiency and precision.

Top Benefits of Using a Rework Station for PCB Repair

Investing in a quality rework station offers numerous advantages, whether you're doing DIY PCB rework at home or handling professional repairs. Here are some key benefits:

- Precision: Hot air tools allow you to target specific components without affecting nearby parts, ideal for rework stations for small components.

- Versatility: A single station can handle soldering, desoldering, and even heat-shrink tubing tasks.

- Time-Saving: Compared to manual desoldering with a wick or pump, a rework station speeds up the process significantly.

- Cost-Effective: Fixing mistakes instead of discarding faulty boards saves money in the long run, especially for hobbyists on a budget.

Step-by-Step Guide to Mastering PCB Rework

Now that you understand the importance of a rework station, let’s walk through the process of performing PCB rework. Whether you're using a beginner rework station or a more advanced setup, these steps will help you achieve professional results.

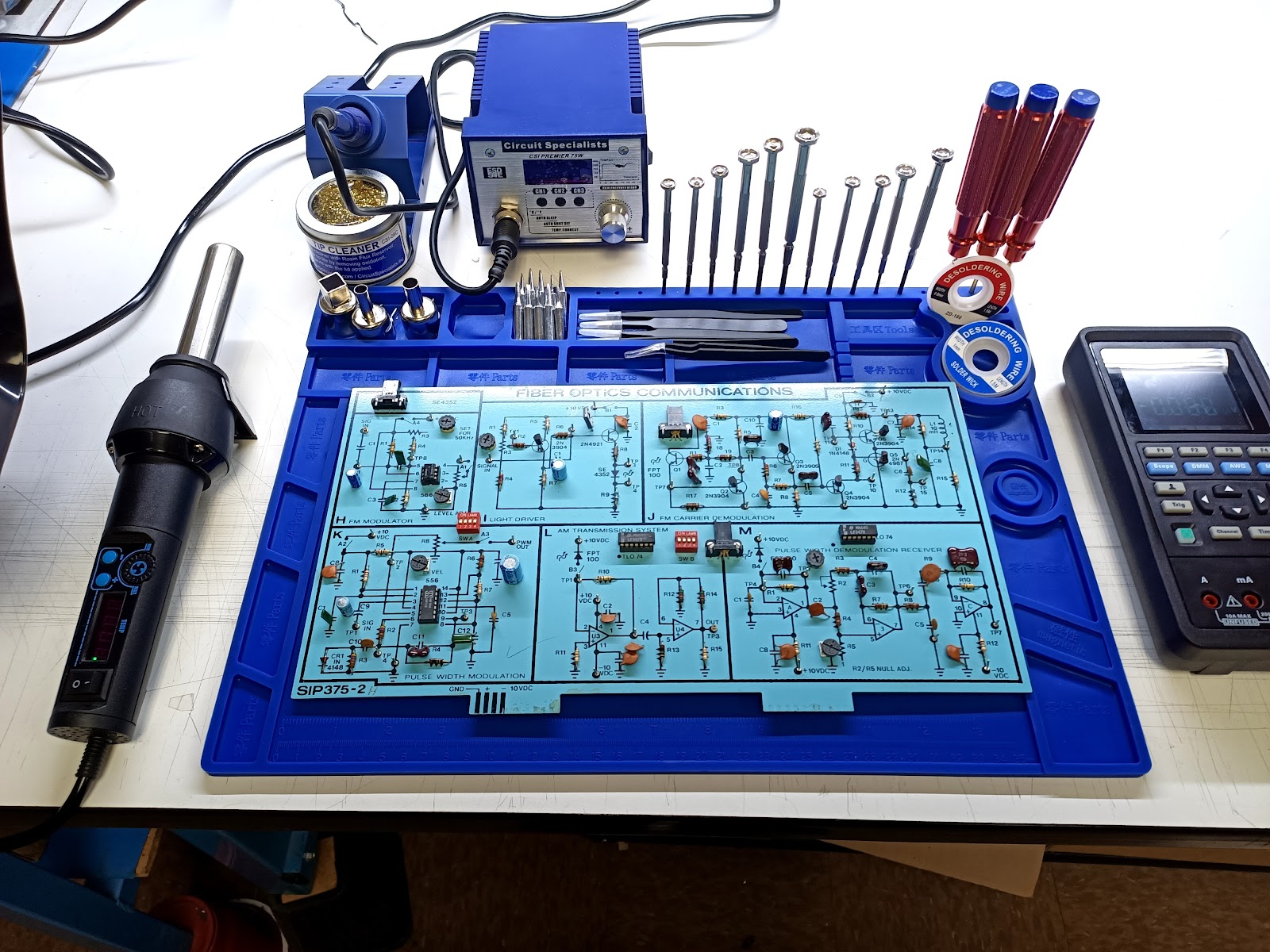

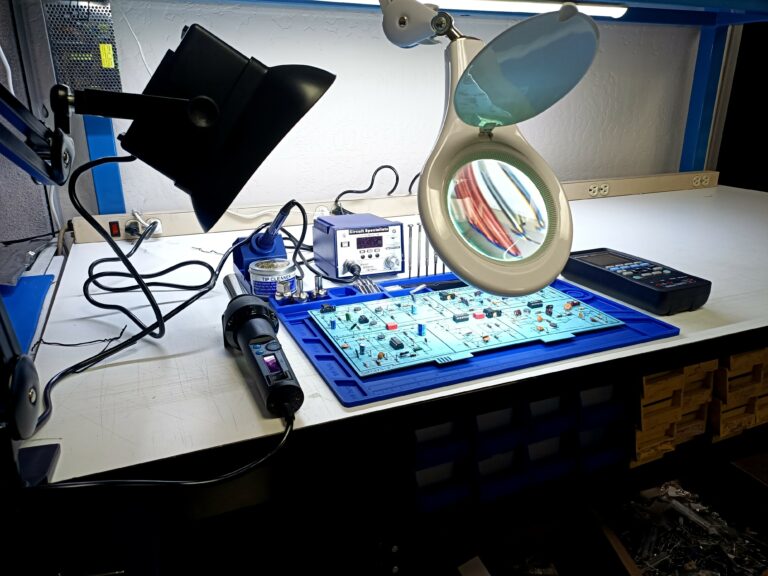

Step 1: Prepare Your Workspace

Start by setting up a clean, well-lit workspace. Gather all necessary tools, including your rework station, tweezers, flux, solder, and a magnifying glass for inspecting small components. Use an anti-static mat or wrist strap to prevent electrostatic discharge (ESD) from damaging sensitive parts.

Step 2: Identify the Issue

Examine the PCB to pinpoint the problem. Is there a bad solder joint, a misplaced component, or a broken trace? For small components, use a magnifying tool to check for issues like cold solder joints, which appear dull and may have a resistance higher than 0.1 ohms, indicating a poor connection.

Step 3: Desolder Components (If Needed)

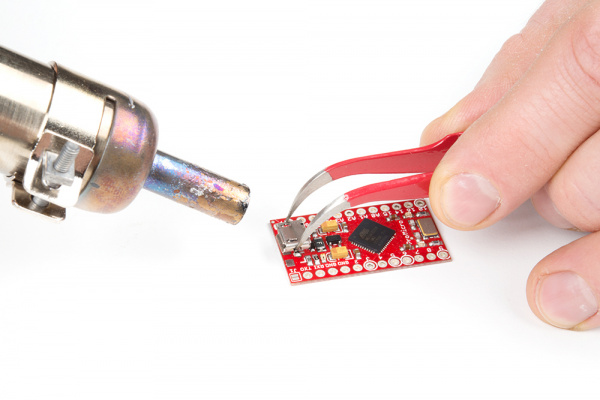

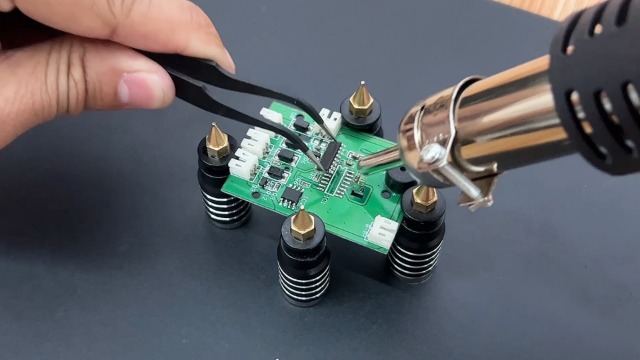

If you need to remove a component, use the hot air tool on your rework station. Set the temperature to around 300°C and the airflow to a low setting (around 30 liters per minute) to avoid overheating. Hold the nozzle 2-3 cm above the component and move it in a circular motion for 10-15 seconds until the solder melts. Use tweezers to gently lift the component off the board.

Step 4: Clean the Area

After removing the component, clean the pads with a desoldering wick and isopropyl alcohol to remove excess solder and residue. This ensures a smooth surface for resoldering and prevents contamination.

Step 5: Solder the New Component

Apply flux to the pads to improve solder flow, then place the new component using tweezers. Use the soldering iron on your soldering rework station at a temperature of 300°C-350°C to apply solder to each pad. Aim for shiny, cone-shaped joints that fully cover the pad without excess solder.

Step 6: Inspect and Test

Once soldering is complete, inspect the joints under magnification for defects. Test the board to confirm the repair worked—use a multimeter to check for continuity or measure resistance across joints (ideal values should be close to 0 ohms for a good connection).

Tips for Hobbyists: Starting with an Affordable Rework Station

If you're just getting started with DIY PCB rework, here are some practical tips to make the most of an affordable rework station for hobbyists:

- Practice First: Use scrap boards to practice soldering and desoldering before working on valuable projects.

- Start Simple: Choose a beginner rework station with basic features to avoid feeling overwhelmed by complex controls.

- Invest in Accessories: Extra nozzles for the hot air tool and a variety of soldering tips can expand the capabilities of even a budget station.

- Watch Tutorials: Online videos can provide visual guidance on using your rework station effectively.

- Stay Safe: Always work in a ventilated area, wear safety glasses, and keep flammable materials away from hot tools.

Scaling Up: Advanced Features for Professionals

As you move from hobbyist to pro, you’ll likely need a rework station with more advanced capabilities. Here are some features to consider when upgrading:

- Programmable Settings: Some high-end stations allow you to save temperature and airflow profiles for specific tasks, improving efficiency.

- Higher Power Output: Look for stations with 700-1000 watts of power for faster heating and better performance on larger boards.

- Additional Tools: Advanced kits may include vacuum pick-up tools or preheating plates to handle complex repairs.

While these stations cost more, they’re worth the investment for professionals handling high-volume or intricate PCB rework.

Common Mistakes to Avoid During PCB Rework

Even with the best soldering rework station, mistakes can happen. Here are some pitfalls to watch out for:

- Overheating Components: Excessive heat can damage parts or lift pads from the board. Stick to recommended temperatures and limit heat exposure to 15-20 seconds per area.

- Using Too Much Force: When desoldering, don’t yank components off the board. Let the solder melt fully before lifting with tweezers.

- Ignoring Safety: Hot air tools and soldering irons can cause burns or fires if mishandled. Always follow safety guidelines.

- Skipping Cleaning: Failing to clean pads after desoldering can lead to poor connections when resoldering.

Conclusion: Take Your PCB Rework Skills to the Next Level

Mastering PCB rework is a game-changer, whether you're a hobbyist experimenting with DIY PCB rework or a professional aiming for flawless repairs. The right rework station for small components can transform your workflow, making tasks faster, easier, and more precise. For beginners, starting with an affordable rework station for hobbyists is a smart choice, while pros can benefit from advanced features for complex projects.

By following the steps and tips in this guide, you’ll be well on your way to tackling any PCB rework challenge with confidence. Remember, practice makes perfect—so grab your beginner rework station, start small, and watch your skills grow. With the right tools and techniques, you’ll soon be creating and repairing circuit boards like a true professional.

ALLPCB

ALLPCB