Overview

Breakthroughs in artificial intelligence (AI) are transforming many sectors, but as algorithm complexity increases and data volumes grow exponentially, traditional storage architectures are becoming a bottleneck for AI applications. Ferroelectric memory's nonvolatility, high-speed read/write performance, and low power consumption are becoming key technologies for enabling more efficient edge computing architectures.

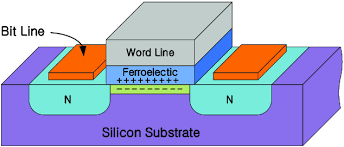

Device Characteristics

The ferroelectric memories SF25C20 and SF25C512 are based on ferroelectric process technology and silicon-gate CMOS process, combining the high-speed access characteristics of RAM with the nonvolatility of ROM. Key advantages include:

- Low power: 4.5 mA active current, standby current as low as 1 uA, suitable for edge devices and mobile terminals.

- High endurance: read/write cycle endurance up to 1e11 cycles, significantly exceeding standard flash and EEPROM devices.

- Long data retention: 10 years at 85°C (200 years at 25°C), ensuring stored data remains intact under extended or harsh conditions.

- High operating frequency: nominal operation at 25 MHz, with support for a 40 MHz high-speed read command to meet applications with higher data access speed requirements.

- Compact packaging: available in SOP8 150 mil and SOP8 208 mil packages, compact and easy to mount and solder, saving PCB space.

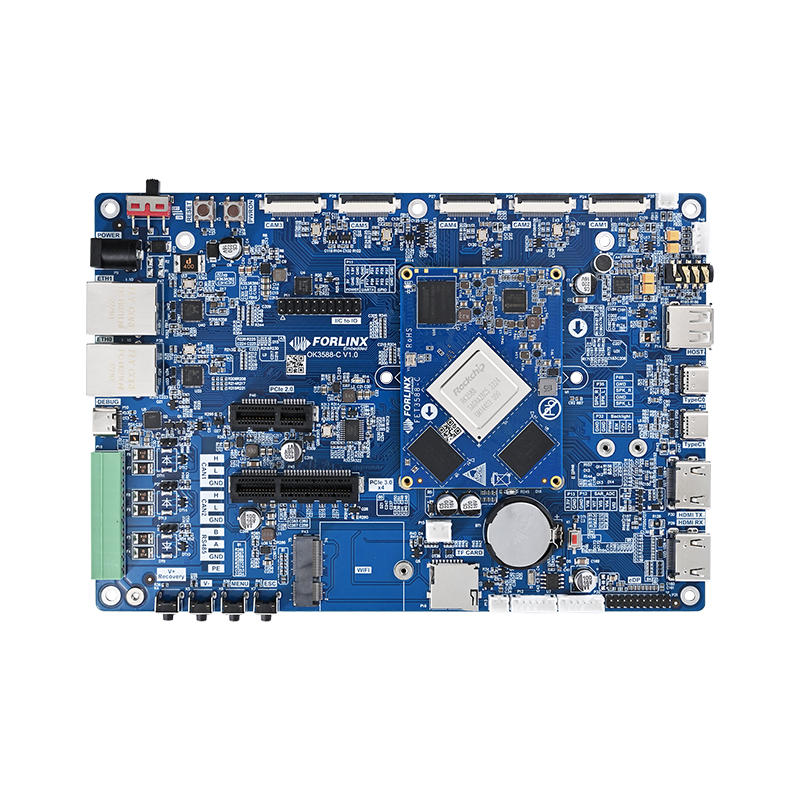

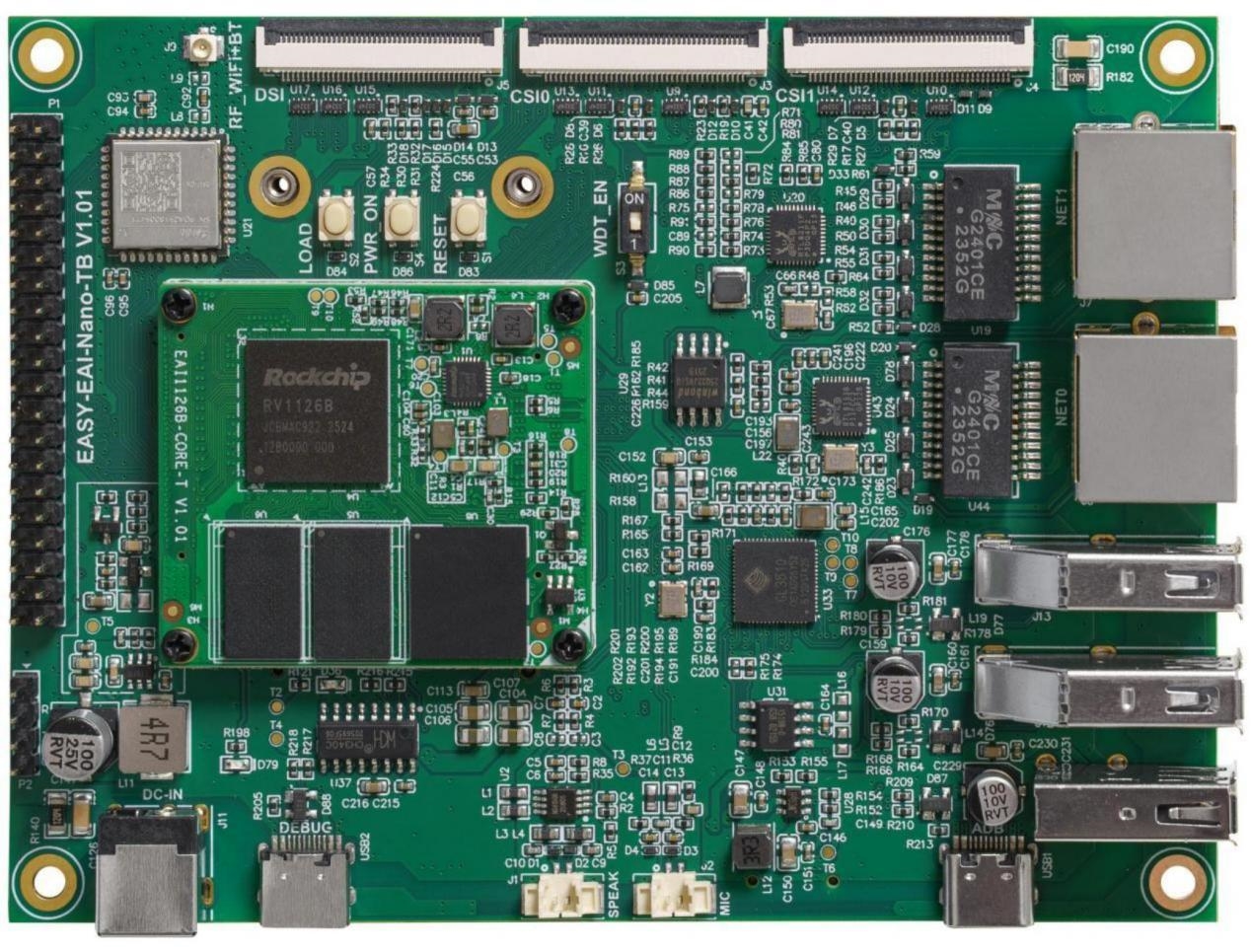

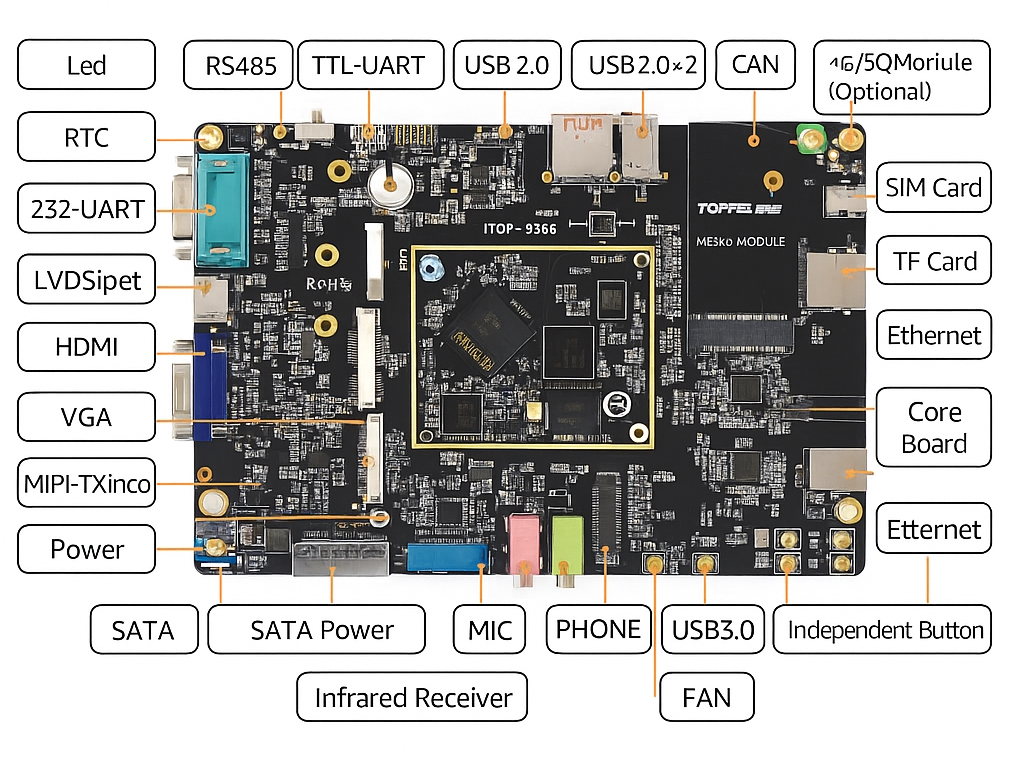

Application in Edge Devices

In edge devices such as smart cameras and drones, SF25C20 and SF25C512 can replace devices like MB85RS2M/FM25V20 and MB85RC512/FM24C512 for local storage of AI model parameters. For example, storing CNN model weights in ferroelectric memory avoids frequent access to external storage, reducing latency and lowering energy consumption from data transfers.

ALLPCB

ALLPCB