If you're a hardware engineer, maker, or student, you've probably used a PCB online quoting tool. It seems simple: upload a file, adjust a few options, and get an instant quote. But have you ever wondered why changing just one parameter can make the price jump so dramatically?

In reality, a complex pricing logic lies behind every online calculator. This article will demystify that process, helping you understand the cost implications of each parameter. We'll use real-world examples to show you how your choices affect the final price and even reveal some "hidden" costs you might not have considered.

Core Parameters: The First Tier of PCB Pricing

These are the fundamental options you'll see on any quoting page. Mastering them is the first step to controlling your budget.

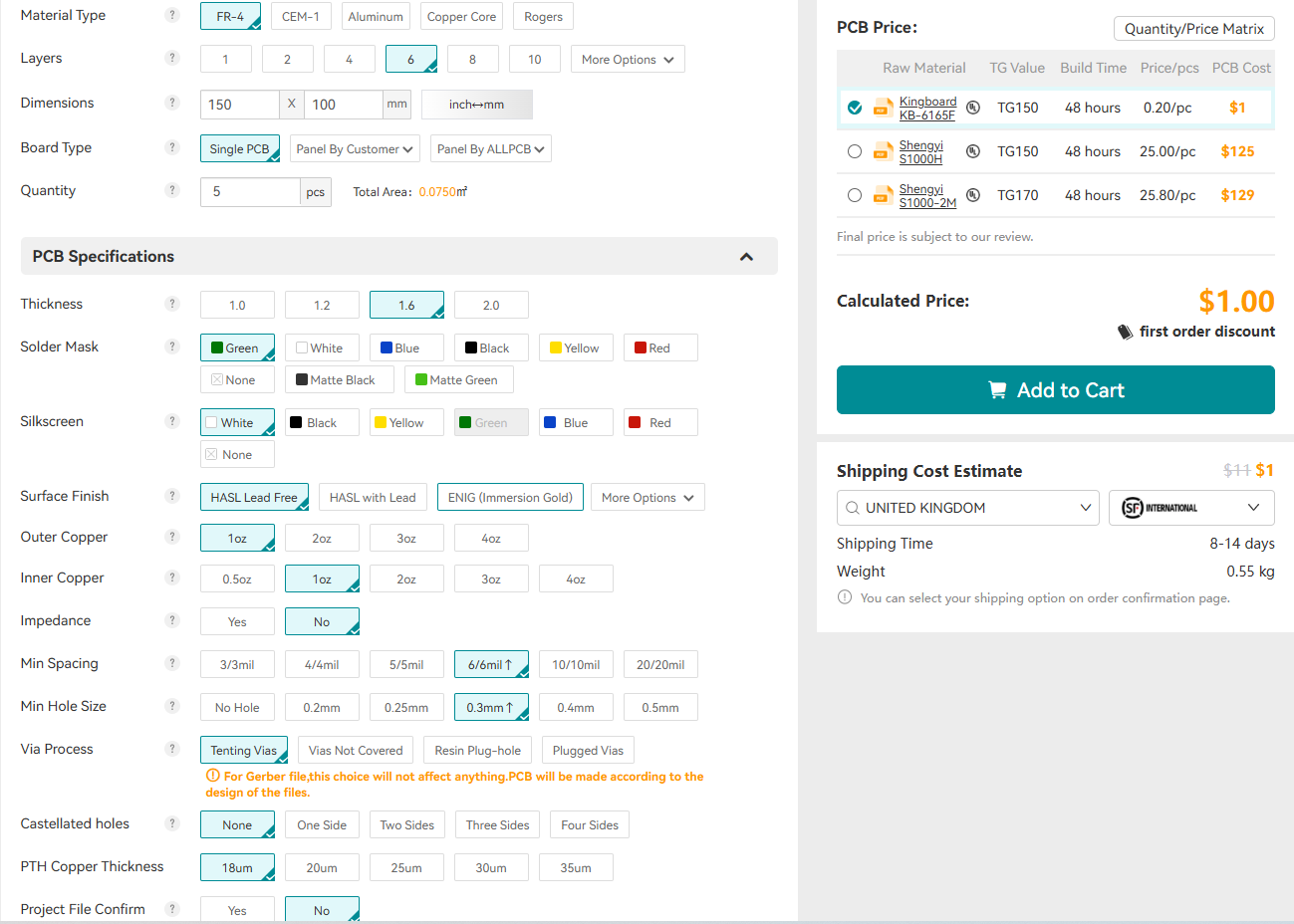

ALLPCB online quoting tool's main interface

- Dimensions & Layer Count: This is the most crucial pricing factor. The board's area and layer count directly determine the amount of raw material and the complexity of the manufacturing process. A larger, multi-layer board requires more time, material, and specialized equipment, all of which contribute to the cost.

- Pro Tip: Design within standard dimensions, especially for prototypes. If your design allows, panelize multiple small boards into a single order to lower the unit cost. ALLPCB's online calculator adjusts the price in real time based on your dimensions, helping you quickly find the best solution.

- Board Material: For most applications, FR-4 is the default and most cost-effective choice. However, for high-frequency signals or better thermal performance, you might need a more advanced material like Rogers. More specialized options like metal core, ceramic, flex, and rigid-flex boards are also available, but their prices are typically much higher.

- Pro Tip: Don't use specialized materials unless necessary. For most consumer electronics, FR-4 is more than adequate. ALLPCB offers a wide range of materials, and our customer service team can help you select the right one for your project.

- Copper Thickness: Standard copper thickness is usually 1 oz (ounce per square foot), sufficient for most low-power designs. If your board handles high current—like in a motor driver or power supply—you'll need thicker copper (2 oz or 3 oz), which increases material costs and makes the etching process more challenging.

- Pro Tip: Increase copper thickness only when necessary. In the design phase, you can optimize current carrying capacity by widening copper traces, which can help you avoid the added cost of thicker copper.

- Surface Finish: The surface finish protects exposed copper from oxidation and prepares it for soldering. Your choice here impacts not only cost but also board reliability.

- HASL (Hot Air Solder Leveling): The most economical option, suitable for most general-purpose boards.

- ENIG (Electroless Nickel Immersion Gold): More expensive, but provides an exceptionally flat, reliable surface crucial for fine-pitch components like BGAs.

- OSP (Organic Solderability Preservative): A lead-free, eco-friendly option that falls between HASL and ENIG in terms of cost.

- Pro Tip: Unless you're using BGAs or other fine-pitch components, HASL is the best value for prototypes and small-batch production.

Case Studies: Seeing the PCB Price Difference in Action

Let's look at some simple scenarios to see how your choices can impact your wallet.

- Case 1: 2-Layer vs. 6-Layer: A standard 100mm x 100mm, 2-layer FR-4 board might be priced around $30. A 6-layer board of the same size, due to the added lamination steps, could easily jump to $100 or more.

- Case 2: HASL vs. ENIG: For a mid-sized board, choosing ENIG over HASL can increase your price by 30-50%. For high-density designs, this cost is worth it, but for a simple design, it's an unnecessary expense.

- Case 3: Standard vs. Expedited Lead Time: A 5-day lead time for a prototype might cost $40. But if you need it in 24 hours, an expedited service could raise the price to over $100. This premium is for priority production to meet your tight deadline.

Advanced Parameters: "Hidden" Costs for PCB Ordering You Might Overlook

Beyond the basic parameters, several less obvious factors can significantly influence your final quote. These are the details that determine whether a board is as cost-effective as possible.

- Minimum Trace/Space: The higher your design's precision, the more challenging the manufacturing process. This impacts the yield rate and drives up the cost.

- Controlled Impedance: If your design requires signal integrity control, you'll need to select a controlled impedance service. This adds extra design and manufacturing steps, such as impedance testing, significantly increasing the cost. If you're not working with high-speed signals, you can skip this option to save money.

- Drill Count & Hole Size: While usually included in the base price, a high number of very small holes increases production time and requires more precise drill bits, which can add to the cost.

- Panelization Efficiency: How you arrange your boards on a larger production panel can dramatically affect the per-board cost. An efficient panel maximizes material usage and significantly reduces costs. ALLPCB's engineers will actively help you optimize your panelization to reduce your costs.

- Testing Method: Flying probe testing is crucial for ensuring the electrical integrity of your board. Many manufacturers only offer free flying probe sampling, meaning only some of your boards are tested. If you need to ensure every single board is 100% functional, you typically have to pay extra for full flying probe testing. Notably, ALLPCB provides full flying probe testing for free, saving you this additional cost.

- Special Processes: Specialty features like gold fingers, press-fit holes, conductive ink, or half-holes all add extra manufacturing steps and cost. AllPCB's quotation tool provides many special process options and strives to standardize every user's requirements.

Why Choose ALLPCB? Transparent, Efficient, and High-Value

You now understand the complexity of quoting. So, let's look at how ALLPCB makes the entire process simple, transparent, and efficient.

- Transparent Pricing, No Hidden Fees: Our online calculator provides an accurate estimated price based on core parameters. For "hidden" factors like panelization efficiency, drill count, and special processes, a professional review engineer conducts a manual check. This ensures the final price you receive is transparent and accurate, with no surprises.

- Free Value-Added Services: We include several services that other companies charge extra for. For example, ALLPCB offers free full flying probe testing and DFM analysis, saving you money on testing and design verification.

- One-Stop Service: Our platform goes beyond just PCBs. By uploading your Bill of Materials (BOM), you can seamlessly transition to our PCBA one-stop assembly service, saving you time and effort.

Conclusion & Your Next Step

Understanding your PCB quote is key to managing your budget and making smart design choices. While it may seem complex, breaking it down into individual factors makes the process clear and controllable.

At ALLPCB, we are committed to making this process simple and transparent. Our intuitive quoting tool and professional review team give you complete control and all the information you need, right at your fingertips.

Ready to experience lightning-fast efficiency and competitive pricing? Get your custom quote on ALLPCB today. As a welcome gift, new customers can get their first prototype starting from just $1.

ALLPCB

ALLPCB