When it comes to designing and manufacturing printed circuit boards (PCBs), selecting the right surface finish through PCB plating is a critical decision. The finish not only protects the copper traces from oxidation but also ensures reliable soldering, enhances durability, and impacts the overall performance of your board. With various options available, how do you choose the best one for your project? This guide will walk you through everything you need to know about PCB surface finish selection, PCB plating materials comparison, PCB plating cost analysis, and the advantages and disadvantages of each option. Whether you're an engineer or a hobbyist, you'll find actionable insights to make an informed decision.

Why PCB Plating and Surface Finish Matter

PCB plating, often referred to as surface finish, serves as a protective layer on the exposed copper areas of a circuit board. Without a proper finish, copper can oxidize, leading to poor solderability and potential failure of the board. The right surface finish improves the board's shelf life, ensures strong connections during assembly, and can even affect signal integrity in high-frequency applications. Choosing the correct finish depends on factors like your project's environment, budget, and performance requirements. In this ultimate guide, we'll break down the options to help you navigate the process of PCB surface finish selection with ease.

What Is PCB Plating and How Does It Work?

PCB plating is the process of applying a thin layer of metal or chemical coating over the copper traces and pads on a circuit board. This layer acts as a barrier against environmental factors like moisture and air, which can cause corrosion. It also provides a suitable surface for soldering components during assembly. Common plating materials include gold, silver, tin, and nickel, often applied through methods like electroless deposition or immersion processes. The choice of material and method impacts the board's durability, conductivity, and cost. Let’s dive deeper into the most popular types of surface finishes and compare their properties through a detailed PCB plating materials comparison.

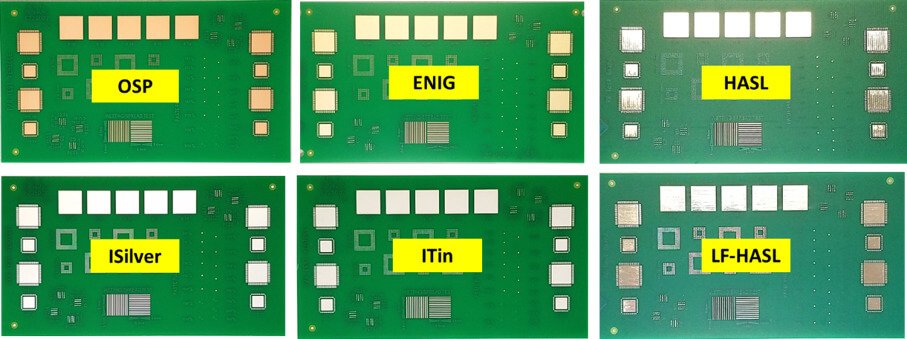

Types of PCB Surface Finishes: A Detailed Comparison

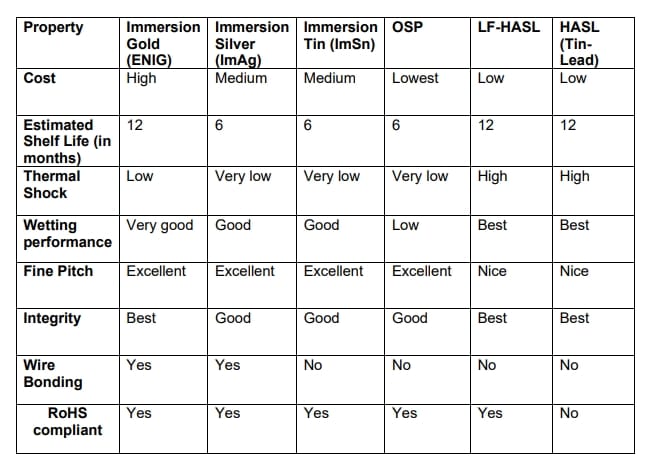

Understanding the different types of PCB surface finishes is the first step in making an informed choice. Below, we compare the most common options in terms of performance, application, and suitability for various projects as part of our PCB plating materials comparison.

1. HASL (Hot Air Solder Leveling)

HASL is one of the most traditional and widely used surface finishes. It involves dipping the PCB into molten solder and then using hot air to remove excess material, leaving a thin, even layer of solder on the copper. HASL is available in both leaded and lead-free versions to comply with environmental regulations like RoHS.

- Advantages: Cost-effective, widely available, and provides excellent solderability for through-hole components.

- Disadvantages: Uneven surface finish, not ideal for fine-pitch components (less than 0.5mm), and poor performance in high-frequency applications due to potential signal loss.

- Best For: General-purpose boards and prototypes where cost is a priority.

2. ENIG (Electroless Nickel Immersion Gold)

ENIG consists of a layer of nickel applied over the copper, followed by a thin layer of gold. The nickel acts as a barrier to prevent copper diffusion, while the gold ensures excellent solderability and corrosion resistance.

- Advantages: Flat surface ideal for fine-pitch components (down to 0.3mm), excellent corrosion resistance, and long shelf life (up to 12 months).

- Disadvantages: Higher cost compared to HASL and potential for "black pad" defects if not applied correctly, which can lead to soldering issues.

- Best For: High-density boards, fine-pitch components, and applications requiring high reliability, such as medical or aerospace devices.

3. Immersion Silver

Immersion Silver involves depositing a thin layer of silver onto the copper through a chemical reaction. It provides a flat surface and good solderability, making it a popular choice for modern electronics.

- Advantages: Excellent conductivity, flat surface for fine-pitch components, and lower cost than ENIG.

- Disadvantages: Prone to tarnishing over time, reducing shelf life (typically 6-12 months), and requires careful handling to avoid contamination.

- Best For: High-speed signal applications due to low signal loss and consumer electronics with shorter shelf-life requirements.

4. Immersion Tin

Immersion Tin applies a thin layer of tin over the copper, providing a cost-effective and flat finish suitable for soldering.

- Advantages: Low cost, flat surface for fine-pitch components, and good solderability.

- Disadvantages: Limited shelf life (around 6 months) due to tin whisker growth, which can cause short circuits, and less durable under thermal stress.

- Best For: Budget-friendly projects with shorter storage times and less demanding environmental conditions.

5. ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

ENEPIG is a premium finish that adds a layer of palladium between nickel and gold, offering enhanced reliability for wire bonding and soldering.

- Advantages: Excellent for both soldering and wire bonding, highly resistant to corrosion, and suitable for fine-pitch components.

- Disadvantages: High cost, making it less common for budget-conscious projects.

- Best For: Advanced applications like high-frequency circuits and semiconductor packaging.

PCB Plating Cost Analysis: Balancing Budget and Performance

Cost is a significant factor in PCB surface finish selection. Here's a breakdown of the relative costs of the finishes discussed, along with factors that influence pricing in this PCB plating cost analysis.

- HASL (Leaded and Lead-Free): The most affordable option, often costing around $0.50 to $1.00 per square foot for standard boards. Lead-free HASL is slightly more expensive due to compliance with environmental standards.

- Immersion Tin and Silver: Moderately priced, ranging from $1.50 to $3.00 per square foot. Silver is slightly more expensive due to better conductivity and performance.

- ENIG: Higher cost, typically between $3.00 and $5.00 per square foot, due to the use of gold and the complex application process.

- ENEPIG: The most expensive, often exceeding $5.00 per square foot, reserved for high-end applications where performance justifies the cost.

Factors like board size, order volume, and manufacturer capabilities can also affect pricing. For small runs or prototypes, opting for a cheaper finish like HASL can save money without sacrificing functionality. For mass production of high-reliability boards, investing in ENIG or ENEPIG may reduce long-term failure rates and save on rework costs.

PCB Plating Advantages and Disadvantages: A Summary

Each surface finish has unique strengths and weaknesses. Here's a concise overview of PCB plating advantages and disadvantages to guide your decision-making process.

- HASL: Affordable and reliable for basic soldering but uneven surfaces limit use with fine-pitch components. Not ideal for high-frequency designs due to signal integrity issues.

- ENIG: Offers a flat surface and long shelf life, perfect for complex designs, but comes at a higher cost and risk of manufacturing defects if not applied properly.

- Immersion Silver: Great for high-speed signals with low signal loss (impedance control within ±10% for 50-ohm traces), but tarnishing reduces shelf life.

- Immersion Tin: Cost-effective and flat, yet prone to tin whiskers and limited durability under thermal cycling (e.g., above 150°C).

- ENEPIG: Superior reliability for advanced applications, supporting signal speeds up to 10 Gbps in high-frequency designs, but the high cost restricts widespread use.

Factors to Consider in PCB Surface Finish Selection

Choosing the right finish requires evaluating several factors specific to your project. Here are key considerations to guide your PCB surface finish selection process:

- Application Environment: Will the PCB operate in harsh conditions like high humidity or temperature extremes (e.g., -40°C to 85°C)? Finishes like ENIG or ENEPIG offer better corrosion resistance for such scenarios.

- Component Type: For fine-pitch components or surface-mount technology (SMT) with spacing below 0.5mm, flat finishes like ENIG or Immersion Silver are essential.

- Signal Integrity: High-frequency applications (above 1 GHz) benefit from finishes with low signal loss, such as Immersion Silver, to maintain impedance control.

- Budget Constraints: If cost is a concern, HASL or Immersion Tin can deliver acceptable performance for less demanding projects.

- Shelf Life: For products with long storage periods before assembly, ENIG provides a shelf life of up to 12 months without degradation.

How to Choose the Right Finish for Your Project

With all the options and factors in mind, follow these steps to narrow down the best surface finish for your PCB:

- Define Project Requirements: Identify the operating environment, component types, and performance needs. For example, a consumer gadget may prioritize cost with HASL, while a medical device demands ENIG for reliability.

- Evaluate Cost vs. Performance: Use the PCB plating cost analysis above to balance your budget with the required durability and functionality.

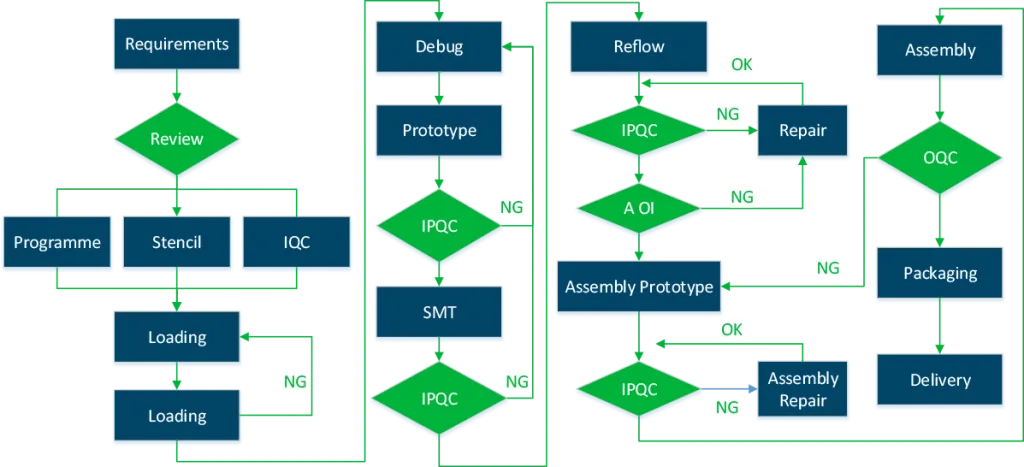

- Consult with Experts: Work closely with your manufacturing partner to confirm the availability and compatibility of the chosen finish with their processes.

- Test Prototypes: If possible, produce a small batch with the selected finish to verify soldering quality and performance before full-scale production.

Common Challenges and How to Avoid Them

Even with careful planning, issues can arise during PCB plating. Here are common challenges and tips to mitigate them:

- Oxidation and Tarnishing: Finishes like Immersion Silver can tarnish if exposed to air for too long. Store boards in vacuum-sealed packaging to extend shelf life.

- Poor Solderability: Defects like "black pad" in ENIG can weaken solder joints. Ensure your manufacturer follows strict quality control during plating.

- Tin Whiskers: With Immersion Tin, tiny metal growths can form over time, risking short circuits. Use conformal coatings or opt for a different finish for critical applications.

Conclusion: Making an Informed Decision for PCB Plating

Selecting the right PCB surface finish is a crucial step in ensuring the reliability, performance, and longevity of your circuit board. By understanding the options through a thorough PCB plating materials comparison, conducting a PCB plating cost analysis, and weighing the PCB plating advantages and disadvantages, you can make a choice that aligns with your project's needs. Whether you prioritize cost with HASL, reliability with ENIG, or high-frequency performance with Immersion Silver, the key is to match the finish to your specific application. At ALLPCB, we're committed to helping you navigate these decisions with expert guidance and high-quality manufacturing solutions tailored to your requirements. Take the insights from this guide and apply them to your next project for optimal results.

ALLPCB

ALLPCB