Understanding PCB lamination temperature control is crucial for achieving high-quality multilayer printed circuit boards. Proper management of temperature during the lamination process ensures optimal resin flow and a consistent curing process, which are essential for the structural integrity and performance of the final product. In this comprehensive guide, we'll explore the key aspects of PCB lamination parameters, including hot plate temperature, temperature ramp rate, and specific considerations for FR-4 lamination temperature. Whether you're an engineer or a manufacturer, this blog will provide actionable insights to improve your PCB production process.

What is PCB Lamination and Why Does Temperature Matter?

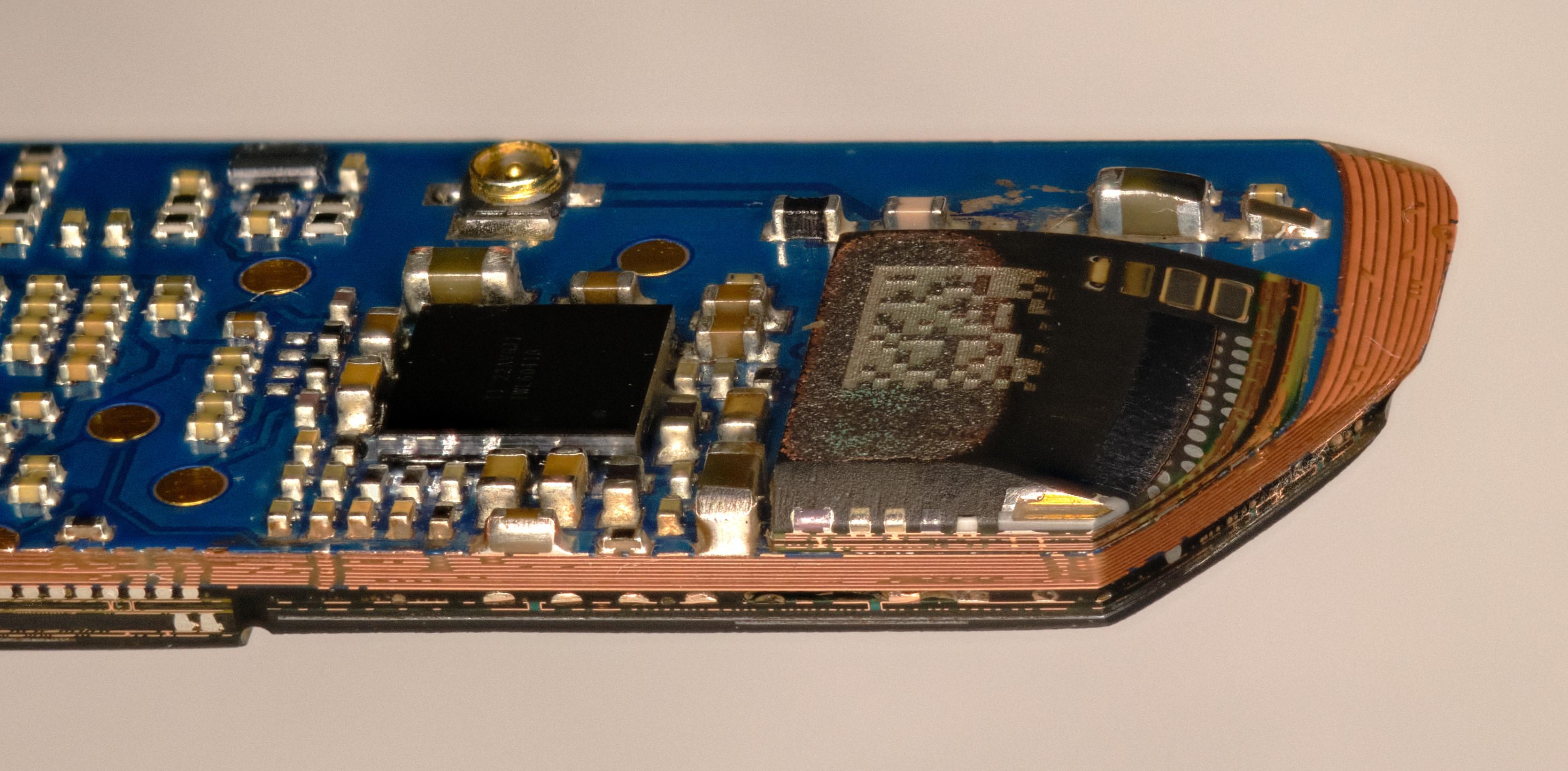

PCB lamination is the process of bonding multiple layers of materials, such as copper foil and insulating dielectric substrates, to form a multilayer printed circuit board. This process relies on heat and pressure to fuse the layers together, ensuring electrical connectivity and mechanical stability. The PCB lamination temperature plays a pivotal role in this process by influencing how the resin in the prepreg (pre-impregnated composite fibers) flows and cures.

If the temperature is too low, the resin may not flow properly, leading to voids or weak bonding between layers. If it's too high, the resin can cure too quickly, causing uneven curing or material degradation. Striking the right balance with hot plate temperature and temperature ramp rate is essential for a successful lamination process, especially when working with common materials like FR-4.

Key Factors in PCB Lamination Temperature Control

To achieve optimal results in PCB lamination, several temperature-related parameters must be carefully managed. Let's break down the most critical factors:

1. Hot Plate Temperature

The hot plate temperature in a lamination press is the primary heat source that drives the resin flow and curing process. For most standard FR-4 materials, the hot plate temperature typically ranges between 180°C and 200°C (356°F to 392°F). This range ensures that the epoxy resin in the prepreg softens and flows to fill gaps between layers before hardening during the curing process.

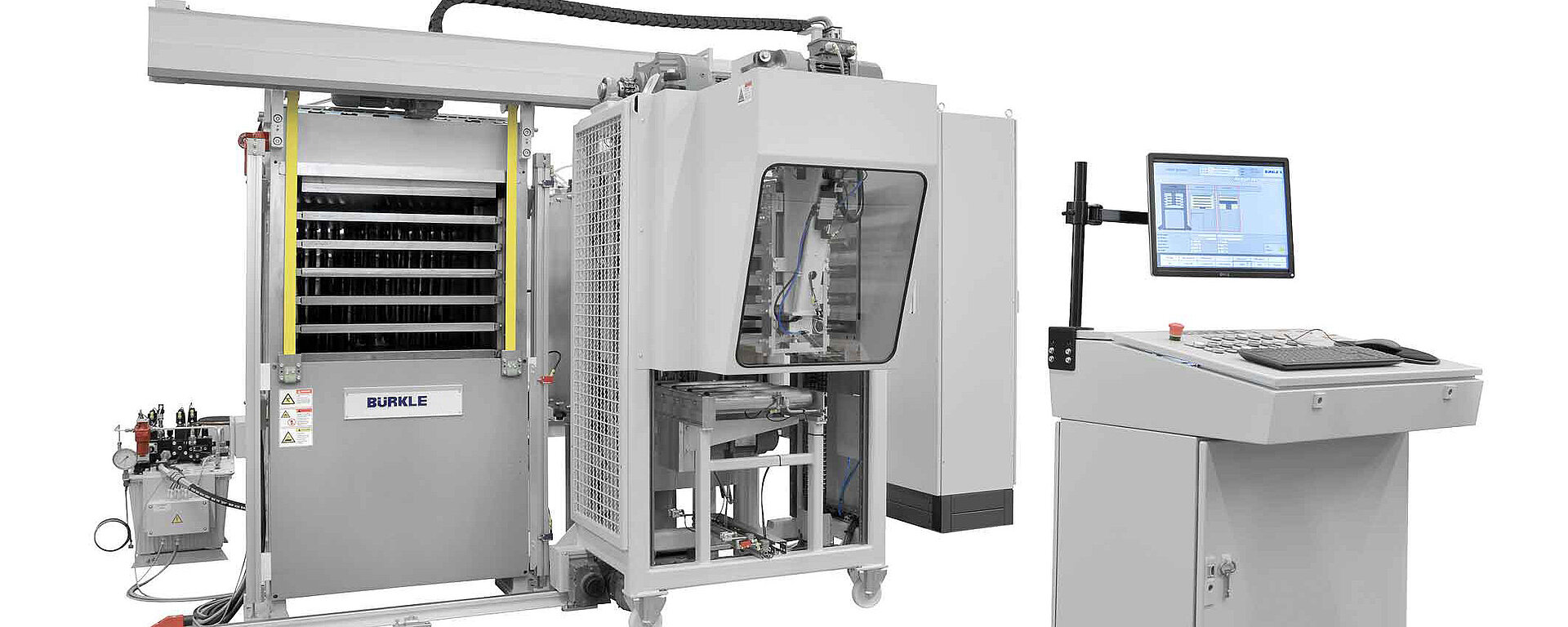

Maintaining a uniform hot plate temperature across the entire surface is vital. Temperature variations as small as 5°C can lead to uneven resin flow, resulting in defects like delamination or incomplete bonding. Modern lamination presses often include advanced temperature control systems to monitor and adjust the hot plate temperature in real time, ensuring consistency.

2. Temperature Ramp Rate

The temperature ramp rate refers to the speed at which the temperature increases or decreases during the lamination cycle. A controlled ramp rate is necessary to prevent thermal shock to the materials, which can cause warping or cracking. For FR-4 laminates, a typical heating ramp rate is around 2°C to 5°C per minute until the target temperature is reached.

A slower ramp rate allows the resin to heat gradually, promoting even resin flow and reducing the risk of trapped air bubbles. During the cooling phase, a controlled ramp rate (often 2°C to 3°C per minute) helps minimize internal stresses in the cured board. Adjusting the ramp rate based on the specific material and stack-up design is a critical part of optimizing PCB lamination parameters.

3. FR-4 Lamination Temperature Specifics

FR-4, a widely used material in PCB manufacturing due to its balance of cost and performance, has specific temperature requirements for successful lamination. The optimal FR-4 lamination temperature generally falls between 180°C and 190°C for most standard grades. At this range, the epoxy resin achieves proper viscosity for flow and cures effectively to form a strong bond.

However, different grades of FR-4 (such as high-Tg or halogen-free variants) may require slight adjustments to the temperature profile. For instance, high-Tg FR-4 materials, designed for better thermal resistance, often need a slightly higher lamination temperature, around 200°C, to ensure complete curing. Always refer to the material manufacturer's datasheet for precise recommendations on PCB lamination temperature and curing times.

Optimizing Resin Flow During Lamination

Resin flow is a critical aspect of the lamination process, as it determines how well the prepreg material fills the spaces between copper layers and bonds the stack-up together. Temperature directly affects the viscosity of the resin—higher temperatures reduce viscosity, allowing better flow, while lower temperatures increase viscosity, potentially leading to incomplete filling.

To optimize resin flow, consider the following:

- Preheat the Stack-Up: Before applying full pressure, preheating the PCB stack-up at a lower temperature (around 100°C to 120°C) for 10-15 minutes can help initiate resin flow without causing premature curing.

- Control Pressure Application: Apply pressure gradually in sync with the temperature increase to avoid forcing resin out of the stack-up too quickly, which can create voids.

- Monitor Resin Content: The resin content in the prepreg (typically 40-50% by weight for FR-4) affects flow characteristics. Higher resin content may require lower temperatures to prevent excessive flow-out.

Balancing temperature and pressure ensures that the resin flows evenly, filling all gaps and creating a uniform bond without squeezing out excessively, which could lead to thin dielectric layers or electrical issues.

The Curing Process: Ensuring Long-Term Reliability

The curing process is the final stage of lamination, where the resin hardens to form a solid, durable structure. Proper curing is essential for the mechanical strength and thermal stability of the PCB. Temperature control during curing directly impacts the degree of cross-linking in the epoxy resin, which determines the material’s final properties.

For FR-4 materials, curing typically occurs at the peak lamination temperature (180°C to 200°C) for a duration of 60 to 120 minutes, depending on the material thickness and stack-up complexity. Insufficient curing time or temperature can result in a partially cured resin, leading to reduced mechanical strength and potential delamination over time. Conversely, over-curing at excessively high temperatures can make the material brittle and prone to cracking.

To ensure a successful curing process:

- Maintain a stable temperature throughout the curing phase to achieve uniform cross-linking.

- Use a controlled cooling phase after curing to avoid thermal stress, which can cause warping or micro-cracks.

- Monitor the glass transition temperature (Tg) of the cured material, as it indicates the thermal performance of the final PCB. For standard FR-4, Tg typically ranges from 130°C to 140°C, while high-Tg variants can reach 170°C or higher.

Common Challenges in Temperature Control and How to Address Them

Even with precise equipment, challenges in PCB lamination temperature control can arise. Here are some common issues and solutions:

1. Uneven Heating

Uneven hot plate temperature distribution can lead to inconsistent resin flow and curing. This is often caused by worn-out equipment or improper calibration. Regularly calibrate the lamination press and inspect the hot plates for wear or damage. Using thermal imaging cameras to map temperature distribution can help identify and correct hot or cold spots.

2. Thermal Shock

Rapid changes in temperature, especially during the cooling phase, can cause thermal shock, leading to material stress and potential defects. Implement a gradual temperature ramp rate during both heating and cooling to minimize stress. For FR-4, cooling rates of 2°C to 3°C per minute are generally safe.

3. Material Variability

Different batches of prepreg or laminate materials may have slight variations in resin content or curing characteristics, affecting the optimal PCB lamination parameters. Always test a small sample of new material batches under controlled conditions to fine-tune temperature and pressure settings before full-scale production.

Best Practices for PCB Lamination Temperature Control

To achieve consistent results in PCB lamination, follow these best practices:

- Use Advanced Equipment: Invest in modern lamination presses with precise temperature and pressure control systems for better repeatability.

- Document Parameters: Record the PCB lamination parameters (temperature, ramp rate, curing time) for each production run to build a reference database for troubleshooting and optimization.

- Train Staff: Ensure that operators are well-trained in managing temperature profiles and recognizing signs of improper lamination, such as voids or delamination.

- Collaborate with Material Suppliers: Work closely with material suppliers to understand the specific temperature requirements for each batch of prepreg or laminate, especially when using specialized FR-4 variants.

Conclusion: Mastering PCB Lamination Temperature for Quality Results

Effective PCB lamination temperature control is the cornerstone of producing reliable, high-performance multilayer circuit boards. By carefully managing hot plate temperature, temperature ramp rate, and other PCB lamination parameters, manufacturers can optimize resin flow and the curing process to ensure strong bonding and long-term durability. Whether you're working with standard FR-4 or specialized materials, understanding and fine-tuning the FR-4 lamination temperature is key to avoiding common defects like delamination or voids.

Implementing the best practices and solutions discussed in this guide will help you achieve consistent, high-quality results in your PCB manufacturing process. With precise temperature control, you can enhance the reliability of your boards and meet the stringent demands of modern electronics applications.

ALLPCB

ALLPCB