In the fast-paced world of electronics manufacturing, achieving zero defects in PCB batch production is a critical goal for engineers and manufacturers. How can you ensure consistent quality in every batch of printed circuit boards (PCBs)? The answer lies in mastering quality control through systematic testing, defect analysis, and proven assurance methods. In this comprehensive guide, we’ll explore actionable strategies for PCB batch quality control, dive into PCB defect analysis, uncover effective PCB quality assurance methods, and outline the best batch PCB testing strategies to help you achieve flawless results.

Why Quality Control Matters in PCB Batch Production

PCBs are the backbone of modern electronics, from smartphones to industrial machinery. A single defect in a batch can lead to costly recalls, damaged reputations, and significant downtime. In batch production, where hundreds or thousands of boards are manufactured simultaneously, even a small error can multiply into a major issue. Effective quality control ensures that every board meets design specifications, performs reliably, and withstands real-world conditions.

Statistics highlight the importance of rigorous quality control: studies show that up to 30% of electronic failures are due to PCB-related issues, such as poor soldering or trace defects. By implementing robust PCB batch quality control processes, manufacturers can reduce failure rates, improve customer satisfaction, and save on rework costs.

"

"

Key Challenges in PCB Batch Production

Batch production introduces unique challenges that can impact quality. Understanding these hurdles is the first step to overcoming them:

- Consistency Across Large Volumes: Ensuring every board in a batch meets the same standards is difficult, especially when producing thousands of units.

- Component Variability: Differences in component tolerances or supplier quality can introduce defects.

- Complex Designs: Modern PCBs often feature high-density layouts with impedance requirements (e.g., 50 ohms for RF applications), making defects harder to detect.

- Environmental Factors: Temperature, humidity, and static electricity during production can affect soldering quality or component placement.

Addressing these challenges requires a multi-layered approach to quality control, combining advanced inspection techniques with proactive defect prevention.

Essential Strategies for PCB Batch Quality Control

To achieve zero defects in PCB batch production, manufacturers must implement a comprehensive quality control framework. Below are key strategies to ensure consistency and reliability.

1. Define Strict Design and Manufacturing Standards

Quality starts with clear specifications. Before production begins, establish detailed design rules and manufacturing tolerances. For example, specify trace widths (e.g., 0.2 mm for high-speed signals) and spacing to prevent crosstalk or short circuits. Use industry standards like IPC-A-610 for acceptability of electronic assemblies to guide your process.

Additionally, collaborate with design teams to perform Design for Manufacturability (DFM) checks. These checks identify potential issues, such as overly tight component placements, before production starts, reducing the risk of defects in the batch.

2. Implement In-Process Inspections

Waiting until the end of production to inspect PCBs can be costly. In-process inspections at critical stages—such as after solder paste application, component placement, and reflow soldering—help catch issues early. For instance, checking solder paste volume (typically 0.8 to 1.2 mm3 per pad) ensures proper joint formation and prevents weak connections.

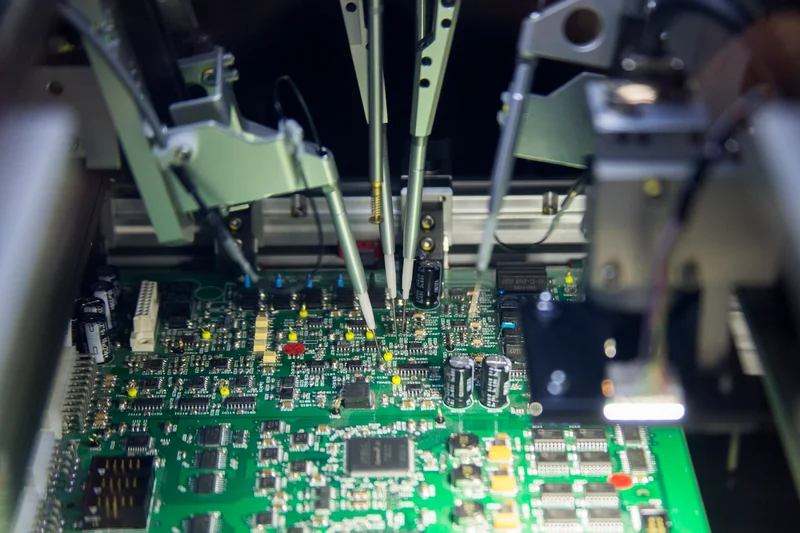

Automated Optical Inspection (AOI) systems are invaluable for in-process checks. These systems use high-resolution cameras to detect misaligned components or insufficient solder with over 95% accuracy, minimizing human error in large batches.

3. Leverage Statistical Process Control (SPC)

Statistical Process Control (SPC) is a data-driven method to monitor production stability. By collecting real-time data on key metrics—like solder joint height or component alignment—manufacturers can detect trends and prevent batch-wide defects. For example, if solder joint heights deviate beyond a control limit (e.g., ±0.1 mm), SPC tools can trigger an alert for immediate corrective action.

SPC reduces the likelihood of producing defective boards by identifying process variations before they escalate into major issues, ensuring consistent PCB batch quality control.

Deep Dive into PCB Defect Analysis

Even with the best quality control measures, defects can occur. Effective PCB defect analysis helps identify root causes and prevent recurrence. Here’s how to approach defect analysis systematically:

1. Categorize Common Defects

Start by understanding the most common defects in PCB batch production:

- Soldering Issues: Cold joints, tombstoning, or solder bridges can disrupt connectivity.

- Component Defects: Misplaced or damaged components (e.g., capacitors with incorrect polarity) can cause circuit failure.

- Trace and Pad Damage: Scratches or breaks in copper traces can lead to open circuits.

- Via Failures: Poorly plated vias can result in high resistance, affecting signal integrity (e.g., increasing impedance beyond 50 ohms for critical paths).

By categorizing defects, you can prioritize inspection efforts and target the most frequent issues.

2. Use Advanced Diagnostic Tools

Identifying the root cause of defects requires the right tools. X-ray inspection, for instance, is ideal for detecting hidden issues like voids in solder joints under Ball Grid Array (BGA) components. These voids can increase thermal resistance, leading to overheating and failure.

Another powerful tool is the In-Circuit Tester (ICT), which checks for electrical continuity and component functionality. ICT can detect open circuits or incorrect resistor values (e.g., a 1kΩ resistor reading 1.2kΩ due to manufacturing variance) with high precision.

3. Conduct Failure Mode Analysis (FMA)

Failure Mode Analysis involves studying how and why defects occur. For example, if a batch shows recurring solder bridges, analyze whether the issue stems from excessive solder paste (e.g., over 1.2 mm3 per pad) or incorrect stencil design. Use this data to refine processes and eliminate root causes, ensuring long-term quality improvements.

Proven PCB Quality Assurance Methods

Quality assurance (QA) goes beyond inspection—it’s about building reliability into every step of the process. Here are essential PCB quality assurance methods for batch production:

1. Pre-Production Validation

Before full-scale production, validate your design and materials. Conduct a First Article Inspection (FAI) on a small batch to confirm that all components, layouts, and soldering meet specifications. For high-speed designs, verify signal integrity by testing for impedance mismatches (e.g., ensuring 50-ohm traces maintain consistency across the batch).

2. Supplier and Material Audits

The quality of raw materials directly impacts the final product. Audit suppliers to ensure they provide components within specified tolerances (e.g., resistors with ±1% variance). Regularly test incoming materials for defects, such as checking laminate dielectric constants (typically 4.5 for FR-4 boards) to avoid signal delays.

3. Environmental Testing

PCBs must perform under real-world conditions. Subject batches to environmental stress tests, including thermal cycling (e.g., -40°C to 85°C) and humidity exposure (up to 85% RH). These tests simulate operating conditions and reveal potential weaknesses, such as delamination or solder joint cracks.

Batch PCB Testing Strategies for Zero Defects

Testing is the final line of defense against defects. Implementing robust batch PCB testing strategies ensures that only flawless boards reach the market. Here are the most effective testing methods:

1. Functional Testing

Functional testing verifies that each PCB performs as intended. For example, in a power supply board, test output voltage (e.g., 5V ±0.1V) and current delivery under load. Automate functional tests for large batches to ensure consistent results and reduce testing time.

2. Burn-In Testing

Burn-in testing involves operating PCBs under elevated temperatures (e.g., 60°C) and voltages for extended periods (typically 24-48 hours). This process identifies early-life failures, such as weak components or soldering defects, before boards are shipped to customers.

3. Boundary Scan Testing

For complex boards with dense layouts, boundary scan testing (JTAG) checks digital circuits without physical probes. It verifies connectivity and logic functionality, detecting issues like stuck-at faults in microcontrollers or FPGAs. This method is especially useful for high-volume batches where manual testing is impractical.

Building a Culture of Continuous Improvement

Achieving zero defects isn’t a one-time effort—it requires ongoing commitment. Foster a culture of continuous improvement by regularly reviewing quality data, training staff on the latest techniques, and investing in advanced tools. For instance, adopting Artificial Intelligence (AI) for defect detection can increase inspection accuracy by up to 20 times compared to manual methods, as seen in modern manufacturing setups.

Track key performance indicators (KPIs) like defect rates per million units (DPMU) and aim to reduce them over time. A target of under 100 DPMU is achievable with consistent effort and data-driven decision-making.

Conclusion: Your Path to Zero Defects in PCB Batch Production

Mastering quality control in PCB batch production is the key to achieving zero defects and delivering reliable products. By focusing on PCB batch quality control, conducting thorough PCB defect analysis, applying proven PCB quality assurance methods, and leveraging effective batch PCB testing strategies, you can minimize errors and maximize customer satisfaction.

Start by implementing the strategies outlined in this guide—define strict standards, use advanced inspection tools, and test rigorously at every stage. With a proactive approach, your PCB batches will consistently meet the highest quality standards, ensuring success in today’s competitive electronics market.

ALLPCB

ALLPCB