Are you looking to extend the lifespan of your printed circuit boards (PCBs) and ensure their reliability in challenging conditions? The secret often lies in selecting the right conformal coating material. This protective layer shields your PCBs from moisture, dust, chemicals, and extreme temperatures, significantly boosting their durability. In this comprehensive guide, we’ll explore everything you need to know about PCB conformal coating material selection, from choosing the best option for high-reliability PCBs to comparing popular materials like acrylic and silicone for harsh environments.

Whether you're an engineer designing for aerospace, automotive, or industrial applications, this blog will walk you through a detailed PCB conformal coating material selection guide, helping you make informed decisions to protect your electronics. Let’s dive into the world of conformal coatings and uncover how they can maximize your PCB lifespan.

What is Conformal Coating and Why Does it Matter for PCBs?

Conformal coating is a thin protective layer applied to the surface of a PCB to safeguard its components from environmental hazards. These coatings "conform" to the shape of the board, covering every nook and cranny to prevent damage from moisture, dust, corrosion, and thermal shock. Without this protection, PCBs can suffer from short circuits, component failure, or degradation over time, especially in harsh environments.

For industries requiring high-reliability PCBs—such as medical devices, military equipment, and automotive systems—conformal coating is not just an option; it’s a necessity. By acting as a barrier against contaminants, these coatings can extend the operational life of a PCB from a few years to decades, depending on the material and application conditions. For example, a well-coated PCB in a humid environment can resist corrosion that might otherwise cause failure within months.

Key Factors in Choosing Conformal Coating for Harsh Environments

When it comes to choosing conformal coating for harsh environments, several factors must be considered to ensure optimal performance. Harsh environments can include extreme temperatures (ranging from -40°C to 150°C in automotive applications), high humidity (up to 95% in tropical climates), chemical exposure (like solvents or fuels in industrial settings), and mechanical stress (vibration in aerospace systems). Here are the critical elements to evaluate:

- Environmental Conditions: Identify the specific threats your PCB will face. For instance, a PCB in a marine environment needs excellent moisture and salt spray resistance, while one in a factory may require protection against chemical vapors.

- Operating Temperature Range: Some coatings, like silicone, can withstand temperatures up to 200°C, while others, like acrylic, may degrade above 120°C.

- Mechanical Stress: If your PCB will experience vibration or flexing, choose a flexible coating like polyurethane or silicone to prevent cracking.

- Application Method: Consider how the coating will be applied—brushing, spraying, dipping, or selective coating. Some materials are better suited to specific methods, affecting cost and coverage.

- Repairability: In case of rework, acrylic coatings are easier to remove compared to epoxy or parylene, which might be critical for prototyping or maintenance.

By aligning the coating properties with your application’s needs, you can ensure long-term reliability even under the toughest conditions.

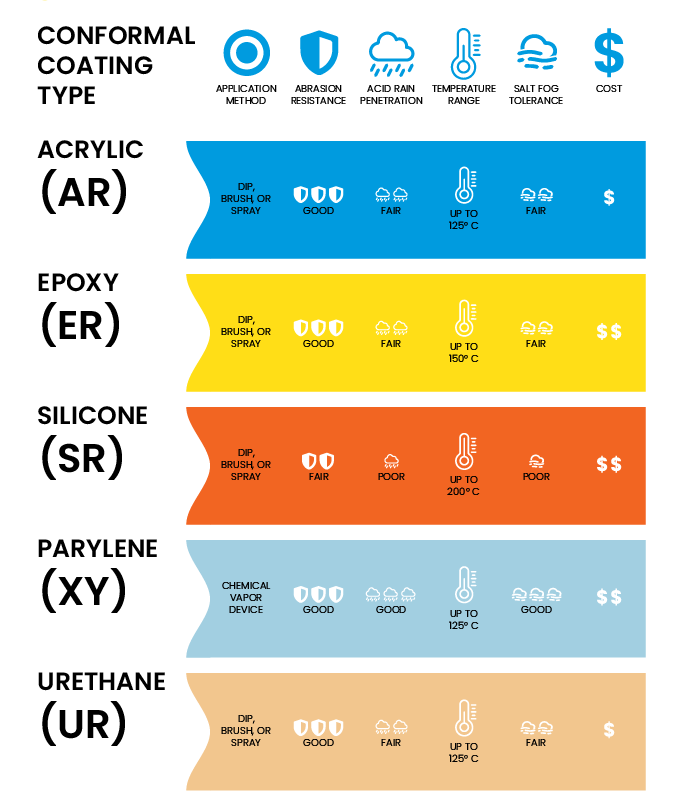

Types of Conformal Coating Materials: A Detailed Comparison

Understanding the different types of conformal coatings is the foundation of a solid PCB conformal coating material selection guide. Below, we compare the most common materials—acrylic, silicone, polyurethane, epoxy, and parylene—focusing on their strengths, weaknesses, and ideal use cases for high-reliability PCBs.

1. Acrylic Conformal Coatings

Acrylic coatings are among the most widely used due to their ease of application and cost-effectiveness. They offer good moisture resistance and dielectric properties, making them suitable for general-purpose applications.

- Pros: Easy to apply and remove, good moisture protection, dielectric strength of around 80-100 kV/mm.

- Cons: Limited resistance to chemicals and high temperatures (typically up to 120°C).

- Best For: Consumer electronics in mild environments, like household appliances.

2. Silicone Conformal Coatings

Silicone coatings excel in extreme temperature ranges and flexibility, making them a top choice for harsh environments. They provide excellent thermal stability and vibration dampening.

- Pros: Wide temperature range (-40°C to 200°C), flexible, good moisture resistance.

- Cons: Harder to remove for rework, moderate chemical resistance.

- Best For: Automotive and aerospace applications with thermal cycling and vibration.

3. Polyurethane Conformal Coatings

Polyurethane offers a balance between flexibility and toughness, with superior chemical resistance compared to acrylic and silicone. It’s ideal for environments with exposure to solvents or fuels.

- Pros: Excellent chemical resistance, good abrasion resistance, flexible.

- Cons: Limited high-temperature performance (up to 130°C), challenging to rework.

- Best For: Industrial equipment exposed to chemicals and mechanical wear.

4. Epoxy Conformal Coatings

Epoxy coatings are known for their durability and robust protection against harsh conditions. They form a hard, rigid layer that’s highly resistant to chemicals and abrasion.

- Pros: Superior chemical and abrasion resistance, high dielectric strength (around 110 kV/mm).

- Cons: Rigid and prone to cracking under thermal expansion, very difficult to remove.

- Best For: Military and marine applications needing extreme durability.

5. Parylene Conformal Coatings

Parylene is a unique, vapor-deposited coating that provides uniform coverage, even in complex geometries. It’s highly reliable but comes at a higher cost.

- Pros: Excellent moisture and chemical resistance, uniform thin layers (as low as 0.1 mil), biocompatible.

- Cons: Expensive, difficult to apply and remove, requires specialized equipment.

- Best For: Medical devices and mission-critical electronics in harsh environments.

Comparing Acrylic vs Silicone Conformal Coatings: Which is Better?

One of the most common debates in conformal coating selection is comparing acrylic vs silicone conformal coatings. Both are popular, but they serve different purposes based on environmental demands and application needs. Let’s break it down:

- Temperature Resistance: Silicone wins with a range of -40°C to 200°C, while acrylic typically handles up to 120°C before degrading.

- Flexibility: Silicone is far more flexible, making it ideal for PCBs subject to vibration or thermal expansion. Acrylic can crack under stress.

- Moisture Protection: Both offer good moisture resistance, but silicone performs better in prolonged high-humidity conditions (above 85% relative humidity).

- Chemical Resistance: Acrylic has limited resistance to solvents and chemicals, while silicone offers moderate protection but may not withstand aggressive substances.

- Ease of Use: Acrylic is easier to apply and rework, often requiring just a brush or spray, while silicone may need curing and is harder to remove.

- Cost: Acrylic is generally more affordable, making it a go-to for budget-conscious projects, whereas silicone’s superior performance comes at a higher price.

For high-reliability PCBs in harsh environments, silicone often emerges as the better choice due to its thermal and mechanical properties. However, for simpler applications in controlled settings, acrylic provides sufficient protection at a lower cost.

Conformal Coating Chemical Resistance Chart

Understanding how different coatings hold up against chemicals is crucial, especially for industrial or automotive applications. Below is a simplified conformal coating chemical resistance chart to guide your selection based on exposure risks. Ratings are on a scale of 1 (poor) to 5 (excellent) based on typical performance against common chemicals like solvents, acids, and fuels.

| Coating Type | Solvents | Acids | Fuels | Salts |

|---|---|---|---|---|

| Acrylic | 2 | 2 | 1 | 3 |

| Silicone | 3 | 3 | 3 | 4 |

| Polyurethane | 4 | 4 | 4 | 4 |

| Epoxy | 5 | 5 | 5 | 5 |

| Parylene | 5 | 4 | 4 | 5 |

This chart highlights that epoxy and parylene are top performers for chemical-heavy environments, while acrylic may not be suitable for applications with frequent solvent or fuel exposure. Use this as a starting point to match your coating to the specific chemicals your PCB will encounter.

Application Techniques for Conformal Coatings

The method used to apply conformal coating can impact its effectiveness and the overall cost of production. Here are the primary techniques used in the industry:

- Brushing: A manual method ideal for small-scale production or rework. It’s cost-effective but inconsistent for large volumes.

- Spraying: Common for medium to large batches, offering quick application via aerosol or automated systems. It may require masking to avoid overspray.

- Dipping: Submerging the PCB in coating material ensures full coverage but can waste material and requires careful control to avoid bubbles.

- Selective Coating: Uses robotic systems to apply coating only where needed, ideal for complex boards with areas that must remain uncoated.

- Vapor Deposition (for Parylene): A specialized process that deposits a uniform, thin layer in a vacuum chamber, ensuring complete coverage even in tight spaces.

Choosing the right application method depends on your production scale, budget, and the specific coating material. For instance, acrylics are often sprayed, while parylene requires vapor deposition for best results.

Tips for Selecting Conformal Coating for High-Reliability PCBs

For conformal coating for high-reliability PCBs, the stakes are higher, as failure can lead to catastrophic consequences in critical systems. Here are actionable tips to ensure your selection meets stringent requirements:

- Prioritize Testing: Conduct environmental stress testing (e.g., thermal cycling from -40°C to 85°C or humidity testing at 85% RH) to validate coating performance before deployment.

- Match Material to Standards: Ensure the coating complies with industry standards like IPC-CC-830 or MIL-I-46058C for military applications.

- Consider Long-Term Aging: Some coatings degrade over time under UV exposure or thermal stress. Select materials with proven longevity data, especially for aerospace or medical devices expected to last 10+ years.

- Balance Cost and Performance: While premium options like parylene offer unmatched protection, they may not be necessary for all projects. Weigh the cost against the required reliability.

Conclusion: Protect Your PCBs with the Right Conformal Coating

Maximizing the lifespan of your PCBs starts with the right conformal coating material. Whether you’re navigating harsh environments with extreme temperatures and chemicals or ensuring reliability for critical applications, understanding the nuances of each coating type is key. From the affordability of acrylic to the rugged durability of epoxy and the precision of parylene, there’s a solution for every need.

By following this PCB conformal coating material selection guide, you can confidently choose the best coating for your project, whether it’s for high-reliability PCBs or surviving harsh environments. Remember to evaluate environmental conditions, compare properties like those in our acrylic vs silicone conformal coatings breakdown, and use tools like the conformal coating chemical resistance chart to make data-driven decisions.

With the right conformal coating, your PCBs will not only survive but thrive, delivering consistent performance over the long haul. Trust in a thoughtful selection process to safeguard your electronics and elevate your designs to new levels of durability.

ALLPCB

ALLPCB