Elevator control printed circuit boards (PCBs) are the heart of modern elevator systems, ensuring safe, efficient, and reliable operation. However, manufacturing these specialized PCBs comes with unique challenges, from design complexity to rigorous quality control. In this comprehensive guide, we’ll explore the key obstacles in elevator PCB manufacturing and provide practical solutions to overcome them. Whether you're an engineer, designer, or manufacturer, this blog will help you navigate PCB assembly challenges, improve SMT assembly for elevator systems, and ensure top-notch PCB quality control and elevator PCB testing.

What Makes Elevator Control PCBs Unique?

Elevator control PCBs are far more than standard circuit boards. They manage critical functions like motor control, safety mechanisms, floor selection, and communication between various elevator components. These boards must operate flawlessly in high-stress environments, often enduring constant vibration, temperature fluctuations, and electrical noise. Because of their role in safety-critical systems, even a minor defect can lead to catastrophic failures, making precision and reliability non-negotiable in elevator PCB manufacturing.

Key Manufacturing Challenges for Elevator Control PCBs

Producing PCBs for elevator systems involves overcoming several hurdles. Below, we dive into the most common PCB assembly challenges and manufacturing obstacles faced in this niche.

1. Design Complexity and Miniaturization

Elevator control systems often require compact designs to fit within limited enclosure spaces. This means cramming numerous components—such as microcontrollers, power regulators, and communication interfaces—onto a small board while maintaining signal integrity. High-density designs can lead to issues like crosstalk, where signals interfere with each other, especially if traces are placed too closely. For instance, signal speeds in modern elevator control boards can exceed 100 MHz, requiring precise impedance control (typically around 50 ohms for high-speed lines) to prevent data loss.

Additionally, these PCBs often need to handle mixed signals—analog for sensors and digital for control logic—adding another layer of complexity to the design process. Without careful planning, this can result in noise coupling and unreliable operation.

2. Harsh Operating Environments

Elevators operate in environments with significant mechanical stress, including vibrations from moving parts and temperature swings ranging from -10°C to 50°C in some installations. These conditions can cause thermal expansion, component fatigue, or solder joint failures over time. Standard PCBs may not withstand such stress, leading to cracks or delamination of board layers if not designed with robust materials.

3. Strict Safety and Regulatory Standards

Elevator systems must comply with stringent safety standards, such as EN 81 in Europe or ASME A17.1 in North America. These regulations often extend to the PCBs, requiring them to pass tests for electromagnetic compatibility (EMC), fire resistance, and electrical insulation. Failing to meet these standards can result in costly redesigns or legal liabilities, making PCB quality control a top priority.

4. Component Sourcing and Supply Chain Issues

Many elevator control PCBs rely on specialized components, such as high-voltage relays or industrial-grade microcontrollers, which may have long lead times or limited availability. A single missing component can halt production, delaying projects and increasing costs. This is a significant PCB assembly challenge, especially for manufacturers working on tight schedules.

5. Assembly Precision in SMT Processes

Surface Mount Technology (SMT) is the go-to method for assembling elevator PCBs due to its efficiency and ability to handle compact designs. However, SMT assembly for elevator systems requires extreme precision. Misaligned components or poor soldering can lead to weak connections, especially for fine-pitch parts like 0.5mm-pitch QFN packages. Additionally, thermal profiling during reflow soldering must be optimized to prevent overheating sensitive components, which could degrade performance or cause failures.

Solutions to Overcome Elevator PCB Manufacturing Challenges

While the challenges in elevator PCB manufacturing are significant, they are not insurmountable. Below are actionable solutions to address these issues and ensure high-quality, reliable elevator control boards.

1. Advanced Design Tools and Simulation

To tackle design complexity, manufacturers should leverage advanced PCB design software with simulation capabilities. These tools can model signal integrity, thermal performance, and power distribution before production begins. For example, running a simulation to ensure impedance matching at 50 ohms for high-speed traces can prevent signal degradation. Additionally, adopting a modular design approach allows for easier updates or repairs, reducing long-term costs.

Layer stacking should also be optimized during the design phase. A typical elevator control PCB might use a 6-layer stack with dedicated ground and power planes to minimize noise. This setup can reduce electromagnetic interference (EMI) by up to 30%, ensuring stable operation even in noisy environments.

2. Use of Durable Materials and Robust Designs

Choosing the right materials is critical for withstanding harsh environments. High-Tg (glass transition temperature) FR-4 laminates, with Tg values above 170°C, offer better resistance to thermal stress compared to standard FR-4. For extreme conditions, consider polyimide-based boards, which can handle temperatures up to 260°C without degrading.

Designers should also incorporate vibration-resistant features, such as thicker copper layers (2 oz or higher) and reinforced mounting holes, to prevent mechanical failures. Adding conformal coatings can protect against dust and moisture, extending the PCB’s lifespan in challenging conditions.

3. Compliance with Safety Standards

To meet regulatory requirements, manufacturers must integrate safety considerations from the design stage. This includes using flame-retardant materials compliant with UL 94V-0 standards and ensuring proper spacing (creepage and clearance distances) for high-voltage areas, often around 3mm for 250V systems. Partnering with testing labs early in the process can help identify potential compliance issues before mass production, saving time and resources.

4. Strategic Component Sourcing

To mitigate supply chain disruptions, manufacturers should establish relationships with multiple suppliers for critical components. Maintaining a buffer stock of high-demand parts, like industrial-grade microcontrollers, can prevent production delays. Additionally, working with a trusted PCB manufacturing partner that offers end-to-end services can streamline sourcing and assembly, reducing the risk of bottlenecks.

5. Precision in SMT Assembly Processes

For SMT assembly in elevator systems, investing in state-of-the-art equipment is essential. Automated optical inspection (AOI) systems can detect misaligned components or solder defects with up to 99% accuracy, ensuring high-quality assembly. Fine-tuning reflow soldering profiles—keeping peak temperatures below 245°C for sensitive components—prevents thermal damage. Regular maintenance of pick-and-place machines also minimizes placement errors, especially for fine-pitch components.

Ensuring Reliability Through PCB Quality Control and Testing

Quality control is the backbone of reliable elevator control PCBs. Without thorough PCB quality control and elevator PCB testing, even well-designed boards can fail in the field. Here’s how to ensure top performance:

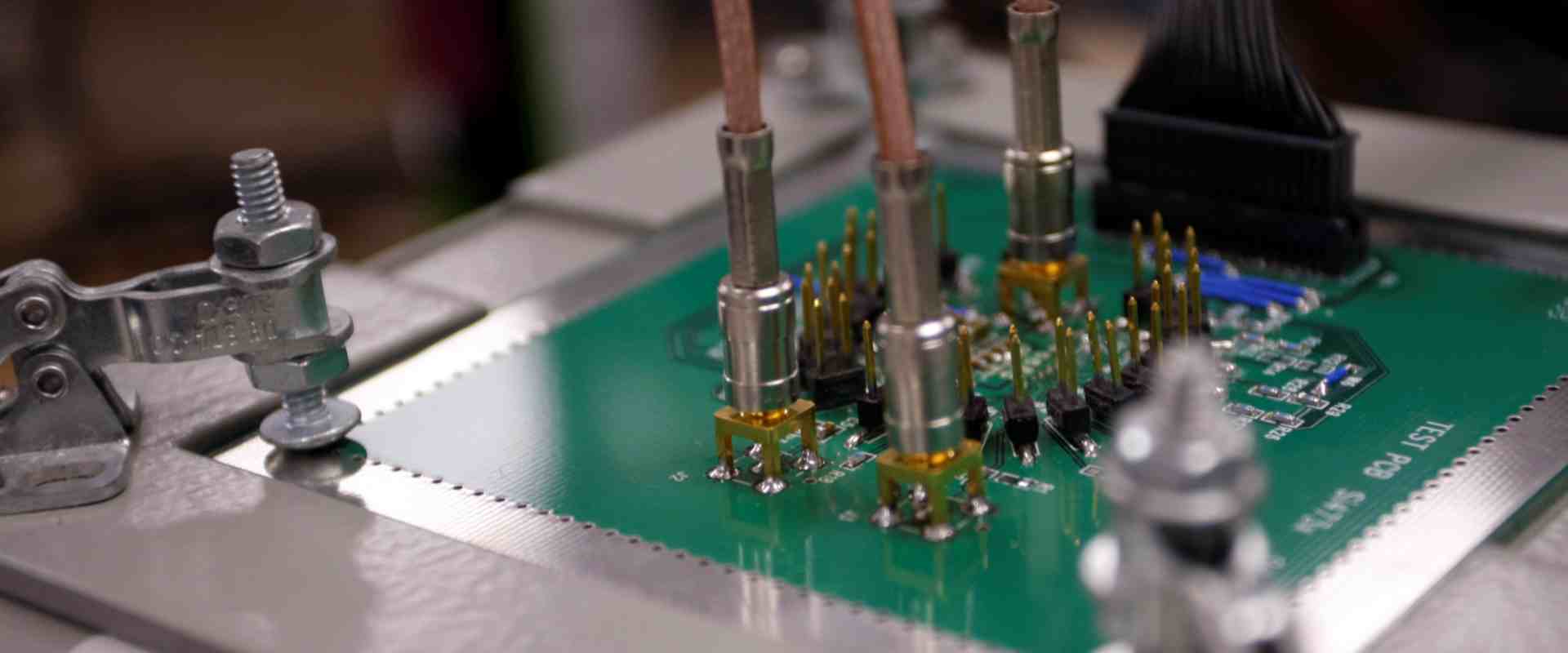

1. In-Circuit Testing (ICT)

ICT checks for shorts, opens, and component functionality on assembled PCBs. By testing each net on the board, ICT can identify issues like incorrect resistor values or missing connections before the board is integrated into an elevator system. This method typically achieves defect detection rates above 90%, making it a critical step in quality assurance.

2. Functional Testing

Functional testing simulates real-world elevator operations to verify the PCB’s performance. This includes testing response times for floor selection (ideally under 100ms) and ensuring safety circuits trigger correctly during fault conditions. Automated test rigs can replicate elevator load conditions, providing accurate insights into board reliability.

3. Environmental Stress Testing

Environmental testing exposes PCBs to temperature cycles (e.g., -20°C to 60°C), humidity (up to 85% RH), and vibration (up to 5G) to simulate long-term use. Boards that pass these tests are more likely to perform reliably in real-world installations. For instance, a well-designed PCB should withstand at least 1,000 thermal cycles without solder joint failure.

Partnering for Success in Elevator PCB Manufacturing

Navigating the complexities of elevator PCB manufacturing requires expertise, precision, and a commitment to quality. By addressing PCB assembly challenges through advanced design, robust materials, and stringent PCB quality control, manufacturers can deliver reliable elevator control boards that meet the highest safety standards. Whether it’s optimizing SMT assembly for elevator systems or conducting thorough elevator PCB testing, every step counts in ensuring seamless elevator operation.

At ALLPCB, we specialize in providing end-to-end solutions for specialized PCB projects like elevator control systems. Our expertise in high-precision manufacturing and rigorous testing ensures that your boards meet the toughest requirements. Let us help you bring your elevator control designs to life with unmatched quality and reliability.

Conclusion

Manufacturing elevator control PCBs is a challenging yet rewarding process. By understanding the unique demands of these boards—complex designs, harsh environments, and strict safety standards—manufacturers can implement solutions that ensure reliability and performance. From leveraging advanced design tools to conducting comprehensive elevator PCB testing, every effort contributes to safer, more efficient elevator systems. With the right approach and a trusted manufacturing partner, overcoming PCB assembly challenges becomes not just possible, but a pathway to innovation in the elevator industry.

ALLPCB

ALLPCB