If you're involved in the design, manufacturing, or procurement of printed circuit boards (PCBs), you’ve likely come across the term UL 796. But what exactly is the UL 796 standard for PCBs, and why does it matter? In simple terms, UL 796 is a safety standard developed by Underwriters Laboratories (UL) that outlines the requirements and testing procedures to ensure PCBs are safe and reliable for use in various applications. This guide will break down everything you need to know about UL 796, from PCB safety certification requirements to detailed testing procedures, helping you navigate this critical aspect of electronics manufacturing with confidence.

Whether you're an engineer, a product manager, or a business owner, understanding UL 796 is essential for ensuring your products meet industry safety standards and perform reliably in the market. Let’s dive into the details of this standard and explore how it impacts PCB production and certification.

What is UL 796 and Why Does It Matter for PCBs?

The UL 796 standard specifically applies to printed wiring boards, which are the foundation of most electronic devices. Established by Underwriters Laboratories, a globally recognized organization for safety testing and certification, UL 796 sets the benchmark for evaluating the safety and performance of PCBs. This standard ensures that PCBs can withstand various environmental and operational stresses without posing risks such as fire hazards, electrical failures, or material degradation.

Why does this matter? For manufacturers, achieving UL 796 certification demonstrates a commitment to quality and safety, building trust with customers and regulatory bodies. For engineers, it provides a clear framework to design boards that meet stringent safety requirements. And for end-users, it guarantees that the electronic products they use are built on safe, reliable components. In industries like automotive, medical, and consumer electronics, where safety is non-negotiable, UL 796 compliance is often a mandatory requirement for market entry, especially in regions like North America.

Key Benefits of UL 796 Certification

- Safety Assurance: Reduces risks of electrical fires, short circuits, and other failures.

- Market Access: Many industries and regions require UL certification for product approval.

- Quality Validation: Signals to customers that your PCBs meet high safety and performance standards.

- Regulatory Compliance: Helps meet legal and industry-specific safety requirements.

Understanding the UL 796 Standard for PCBs

The UL 796 standard focuses on the materials, construction, and performance of PCBs to ensure they are safe under normal and abnormal operating conditions. It covers both rigid and flexible printed wiring boards used in a wide range of applications. The standard evaluates factors like flammability, thermal endurance, electrical insulation, and mechanical strength to determine if a PCB can safely handle the demands of its intended use.

One of the core aspects of UL 796 is the classification of PCBs based on their flammability rating. This is often tied to the materials used in the board’s construction, such as the laminate and solder mask. For example, a common flammability rating under UL 796 is 94V-0, which indicates that the material self-extinguishes within 10 seconds after being exposed to a flame and does not produce flaming drips. This rating is critical for applications where fire safety is a top concern.

Key Areas Covered by UL 796

- Material Safety: Ensures that PCB materials resist ignition and limit flame spread.

- Electrical Performance: Tests insulation resistance and dielectric strength to prevent short circuits or breakdowns.

- Thermal Stability: Evaluates how well the board withstands high temperatures without degrading.

- Mechanical Durability: Assesses the board’s ability to endure physical stress during assembly and use.

By addressing these areas, UL 796 provides a comprehensive framework for ensuring that PCBs are safe and reliable across various operating conditions.

PCB Safety Certification Requirements Under UL 796

Achieving UL 796 certification for your PCBs involves meeting a set of strict requirements. These requirements are designed to validate the safety and reliability of the board throughout its lifecycle, from manufacturing to end-use. Below, we’ll outline the key PCB safety certification requirements under UL 796 to give you a clear picture of what’s involved.

1. Material Selection and Compliance

The materials used in PCB manufacturing must meet specific safety criteria. This includes the substrate (like FR-4, a common glass-reinforced epoxy laminate), copper cladding, and protective coatings. Materials are tested for flammability, toxicity, and thermal endurance. For instance, FR-4 materials often need to achieve a 94V-0 flammability rating, meaning they must resist burning for a specified duration under test conditions.

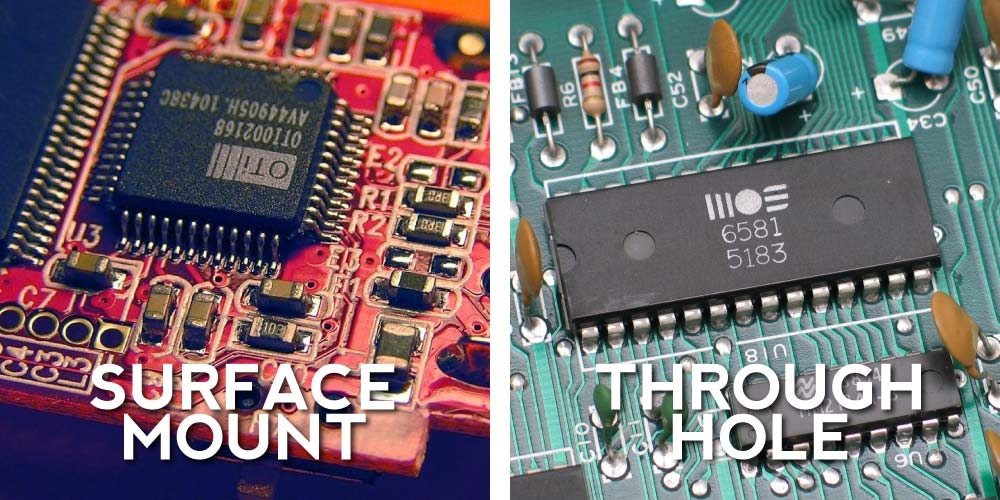

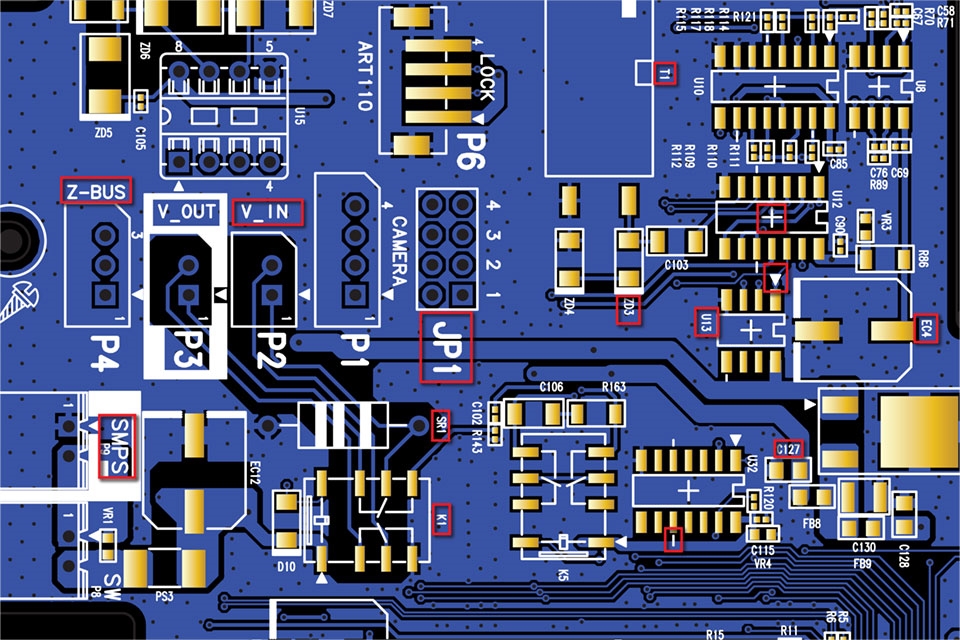

2. Design and Construction Standards

The design of the PCB must adhere to guidelines that minimize safety risks. This includes maintaining adequate spacing between conductive traces to prevent arcing (typically a minimum of 0.25 mm for low-voltage applications, though this varies based on voltage levels), ensuring proper insulation, and using appropriate trace widths to handle current loads. For example, a trace carrying 1 amp of current might require a width of at least 0.5 mm on a standard 1 oz copper layer to avoid overheating.

3. Marking and Documentation

Certified PCBs must bear the UL Recognized Component Mark, along with specific identifiers like the manufacturer’s name and file number. Additionally, documentation must be provided to trace the materials and processes used in manufacturing, ensuring transparency and accountability.

4. Environmental and Operational Testing

PCBs must undergo testing to simulate real-world conditions. This includes exposure to high humidity (up to 85% relative humidity), temperature extremes (often ranging from -40°C to 85°C), and electrical stress (such as applying voltages up to 500V or more to test insulation). These tests ensure the board remains functional and safe under challenging conditions.

UL 796 Testing Procedures: What to Expect

The testing procedures for UL 796 certification are rigorous and methodical, designed to evaluate every aspect of a PCB’s safety and performance. Understanding these UL 796 testing procedures can help manufacturers prepare their products for certification and avoid costly delays. Here’s a detailed look at the key tests involved.

1. Flammability Testing

This test assesses how resistant the PCB materials are to ignition and flame spread. A small flame is applied to the material for a set duration (typically 10 seconds), and the response is observed. For a 94V-0 rating, the material must stop burning within 10 seconds after the flame is removed and must not drip flaming particles. This test is crucial for ensuring the board won’t contribute to fire hazards in electronic devices.

2. Dielectric Strength Testing

Dielectric strength measures the PCB’s ability to withstand high voltages without breaking down. During this test, a voltage (often exceeding 1000V) is applied across the insulation layers for a specified time (usually 60 seconds). If no breakdown occurs, the board passes. This ensures the PCB can handle voltage spikes without failing.

3. Thermal Aging Testing

Thermal aging tests expose the PCB to elevated temperatures (often 105°C or higher) for extended periods (up to 7 days or more) to simulate long-term use. The board’s physical and electrical properties are measured before and after to check for degradation. For instance, a board might lose less than 5% of its insulation resistance to pass this test, ensuring it remains reliable over time.

4. Mechanical Stress Testing

This test evaluates the PCB’s durability under physical stress, such as bending or vibration. For flexible PCBs, a bending test might involve folding the board thousands of times (e.g., 10,000 cycles) to ensure it doesn’t crack or lose conductivity. For rigid boards, vibration tests simulate conditions in automotive or industrial applications, ensuring components remain secure.

5. Environmental Stress Testing

Environmental tests expose the PCB to conditions like high humidity, salt spray (for corrosion resistance), and thermal cycling. A typical thermal cycling test might alternate between -40°C and 85°C for 100 cycles to check for cracking or delamination. These tests confirm that the board can operate safely in harsh environments.

How to Prepare for UL 796 Certification

Navigating the UL 796 certification process can seem daunting, but with the right preparation, it becomes manageable. Here are actionable steps to ensure your PCBs are ready for testing and certification.

1. Choose Compliant Materials

Work with suppliers who provide materials with documented UL ratings. Verify that laminates, solder masks, and other components meet the necessary flammability and thermal endurance standards before starting production.

2. Design with Safety in Mind

Incorporate safety features into your PCB design from the start. This includes proper trace spacing, adequate insulation, and thermal management features like heat sinks or vias to dissipate heat. Use design software to simulate stress points and ensure compliance with UL guidelines.

3. Partner with a Certified Manufacturer

Collaborate with a manufacturing partner experienced in producing UL-certified PCBs. They can guide you through the process, from material selection to final testing, ensuring every step aligns with UL 796 requirements.

4. Conduct Pre-Testing

Before submitting your PCBs for official UL testing, perform internal or third-party pre-testing to identify potential issues. This can save time and money by addressing problems like insufficient insulation or flammability risks early on.

5. Maintain Detailed Records

Keep thorough documentation of materials, design specifications, and manufacturing processes. This is essential for traceability and may be required during the certification process to demonstrate compliance.

Common Challenges in Achieving UL 796 Certification

While the goal of UL 796 certification is clear, the path to achieving it can present challenges. Being aware of these hurdles can help you address them proactively.

- Material Failures: Non-compliant materials can fail flammability or thermal tests, requiring costly redesigns. Always source materials with verified UL ratings.

- Design Oversights: Inadequate trace spacing or poor thermal management can lead to test failures. Double-check designs against UL guidelines.

- Testing Costs: The certification process can be expensive, especially for small businesses. Budget for testing fees and potential re-tests.

- Time Delays: Testing and certification can take weeks or months. Plan your production timeline accordingly to avoid missing market deadlines.

Why UL 796 Certification is a Game-Changer for Your Business

Achieving UL 796 certification isn’t just about meeting a regulatory requirement—it’s a strategic advantage. It positions your products as safe and reliable in the eyes of customers, giving you a competitive edge in industries where trust is paramount. Whether you’re targeting the medical sector, where equipment failure can have life-threatening consequences, or the consumer electronics market, where safety recalls can damage brand reputation, UL 796 certification shows that you prioritize quality.

Moreover, certification can open doors to international markets. Many regions recognize UL standards as a benchmark for safety, making it easier to gain regulatory approval and expand your business globally. In short, investing in UL 796 certification is an investment in your brand’s credibility and long-term success.

Conclusion: Navigating UL 796 with Confidence

Understanding the UL 796 standard for PCBs is a critical step for anyone involved in electronics manufacturing. From meeting PCB safety certification requirements to navigating UL 796 testing procedures, this guide has covered the essentials to help you ensure your products are safe, reliable, and market-ready. By focusing on compliant materials, thoughtful design, and thorough preparation, you can streamline the certification process and position your business for success.

ALLPCB

ALLPCB