In the fast-paced world of retail technology, managing heat in printed circuit boards (PCBs) is critical. Devices like point-of-sale systems, inventory scanners, and digital signage must run efficiently without overheating. This is where thermal via PCB design comes into play. Thermal vias are small, heat-conducting pathways in a PCB that help transfer heat away from critical components, ensuring optimal performance and longevity.

In this comprehensive guide, we’ll explore how thermal vias contribute to PCB thermal management retail applications, their role in heat dissipation PCB design, and practical tips for integrating them into cooling PCB retail hardware. We’ll also touch on using thermal simulation PCB tools to optimize designs. Whether you're an engineer or a tech designer in the retail sector, this post offers actionable insights to enhance your PCB projects.

Why Thermal Management Matters in Retail Tech

Retail technology operates in demanding environments. Devices are often running 24/7, handling high processing loads in compact spaces with limited airflow. Without proper PCB thermal management retail solutions, components can overheat, leading to reduced performance, system failures, or even permanent damage. For instance, a point-of-sale terminal processing hundreds of transactions daily generates significant heat from its processor and power components. If this heat isn’t managed, it could cause system crashes at peak business hours.

Thermal vias are a proven solution for heat dissipation PCB challenges. By creating direct paths for heat to move from hot components to cooler areas or heat sinks, they help maintain safe operating temperatures. This not only improves reliability but also extends the lifespan of retail hardware, reducing maintenance costs.

What Are Thermal Vias and How Do They Work?

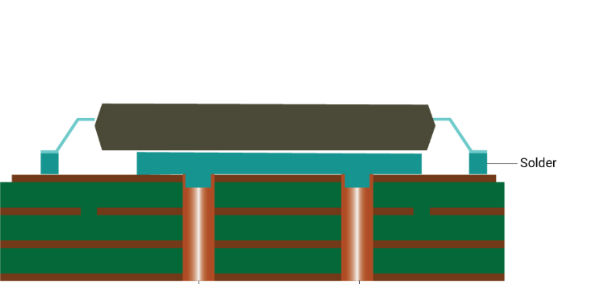

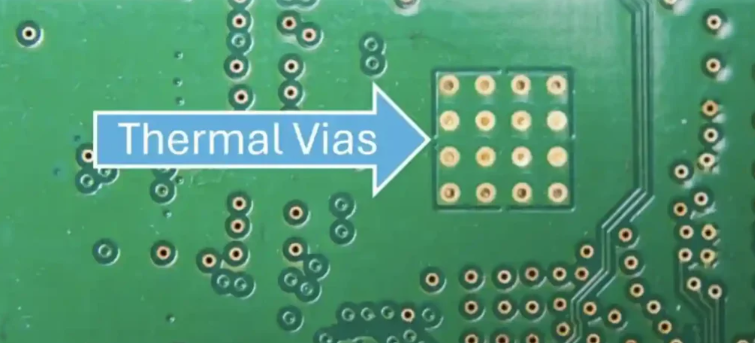

Thermal vias are small holes drilled into a PCB, typically filled or plated with a conductive material like copper. They act as conduits for heat, transferring it away from high-temperature areas, such as power ICs or processors, to a ground plane, heat sink, or other cooling mechanism. Unlike signal vias, which carry electrical signals, thermal vias are dedicated to heat dissipation PCB purposes.

The effectiveness of thermal vias depends on several factors, including their size, placement, and the thermal conductivity of the materials used. For example, a typical thermal via might have a diameter of 0.3 mm to 0.5 mm, with a copper plating thickness of 1 oz/ft2 or higher to maximize heat transfer. In retail tech, where space is often limited, strategically placing these vias under or near heat-generating components can make a significant difference in cooling performance.

In a practical scenario, imagine a handheld inventory scanner used in a busy warehouse. The device’s processor generates heat during continuous operation. Thermal vias placed directly beneath the processor chip can channel heat to a larger copper plane on the opposite side of the PCB, dissipating it more effectively and preventing thermal throttling.

Benefits of Thermal Vias in Cooling PCB Retail Hardware

Integrating thermal vias into PCB designs offers several advantages for retail technology. Here are some key benefits tailored to cooling PCB retail hardware:

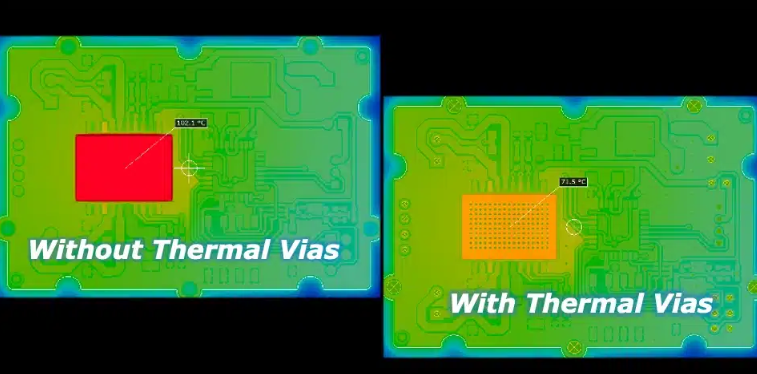

- Enhanced Heat Dissipation: Thermal vias provide a direct path for heat to escape, reducing hotspot temperatures by up to 20-30% in some designs, depending on via density and placement.

- Compact Design Support: Retail devices often have small form factors. Thermal vias allow for effective cooling without the need for bulky heat sinks or fans, saving valuable space.

- Cost-Effective Solution: Compared to active cooling systems like fans, thermal vias are a passive, low-cost method to manage heat, ideal for budget-conscious retail hardware projects.

- Improved Reliability: By maintaining lower operating temperatures, thermal vias reduce the risk of component failure, ensuring retail tech devices perform consistently even under heavy workloads.

Best Practices for Thermal Via PCB Design

Designing a PCB with thermal vias requires careful planning to maximize their effectiveness. Below are actionable tips for engineers working on thermal via PCB design for retail tech applications:

1. Optimize Via Placement

Place thermal vias as close as possible to heat-generating components, such as CPUs, GPUs, or power regulators. Positioning vias directly under or adjacent to these components ensures efficient heat transfer. For instance, in a digital signage display controller, placing a grid of 10-15 thermal vias beneath the main processor can significantly lower its junction temperature.

Suggested Reading: The Ultimate Guide to Thermal Via Placement: Cooling Your PCB Effectively

2. Use the Right Via Size and Spacing

The diameter and spacing of thermal vias impact their cooling efficiency. Smaller vias (0.3-0.5 mm) in a dense grid pattern often work best for high-heat areas, as they maximize the surface area for heat conduction. However, ensure vias are not so close that they compromise the structural integrity of the PCB. A spacing of 1.2-1.5 times the via diameter is generally recommended.

3. Connect to Copper Planes

Thermal vias should connect to large copper planes or ground layers, which act as heat spreaders. A copper plane with a thickness of 2 oz/ft2 or more can absorb and distribute heat effectively, reducing localized hotspots. In retail tech like payment terminals, connecting vias to a ground plane can help maintain stable operation during peak usage.

4. Consider Via Filling

Filling thermal vias with conductive materials, such as copper or thermal epoxy, enhances their heat transfer capability. While filled vias are more expensive, they can reduce thermal resistance by up to 10-15%, making them a worthwhile investment for high-performance retail hardware.

5. Balance with Electrical Design

While thermal vias are essential for cooling, they can interfere with signal integrity if placed near high-speed traces. Use PCB design software to simulate both thermal and electrical performance, ensuring that vias don’t create unwanted capacitance or noise in critical circuits.

Using Thermal Simulation PCB Tools for Better Design

Before finalizing a PCB design, it’s crucial to validate its thermal performance using thermal simulation PCB tools. These software solutions model heat flow and predict temperature distribution across the board, helping engineers identify potential issues and optimize thermal via placement.

For retail tech, where devices must operate reliably in varied conditions, thermal simulation is invaluable. For example, simulating a PCB for a self-checkout kiosk can reveal whether the thermal vias under the processor are sufficient to keep temperatures below the maximum threshold of 85°C during continuous operation. If not, designers can adjust via density or add additional cooling features.

Common simulation tools allow users to input parameters like component power dissipation (e.g., 5W for a processor), ambient temperature (e.g., 25°C), and PCB material properties (e.g., FR-4 with a thermal conductivity of 0.3 W/m·K). The software then generates a thermal map, showing areas of concern and guiding design improvements. By leveraging these tools, engineers can achieve a 15-25% reduction in peak temperatures through iterative design adjustments.

Challenges and Limitations of Thermal Vias in Retail Tech

While thermal vias are highly effective for heat dissipation PCB designs, they’re not without challenges. Understanding these limitations can help engineers make informed decisions when designing cooling PCB retail hardware.

- Space Constraints: In compact retail devices, there may not be enough room to place an optimal number of thermal vias without interfering with other components or traces.

- Manufacturing Costs: Adding a high density of thermal vias or using filled vias increases production costs, which may be a concern for large-scale retail tech deployments.

- Diminishing Returns: Beyond a certain point, adding more thermal vias offers minimal improvement in cooling. For example, increasing via density beyond 25 vias per square centimeter may only reduce temperature by an additional 1-2°C.

To address these challenges, engineers can combine thermal vias with other cooling methods, such as heat sinks or thermal pads, for a balanced approach to PCB thermal management retail applications.

Real-World Applications in Retail Technology

Thermal vias are widely used in retail tech to ensure reliable operation. Here are a few examples of how they contribute to cooling PCB retail hardware:

- Point-of-Sale Terminals: These devices handle high transaction volumes, generating heat from processors and power circuits. Thermal vias help maintain safe temperatures, preventing crashes during busy periods.

- Digital Signage: Displays in retail environments often run continuously, with controllers prone to overheating. Strategic thermal via placement ensures consistent performance.

- Inventory Scanners: Handheld scanners used in warehouses face thermal challenges due to compact designs. Thermal vias provide passive cooling without adding bulk.

By incorporating thermal vias, manufacturers can build retail tech that withstands the rigors of daily use, delivering value to businesses and customers alike.

Suggested Reading: Case Studies: Successful PCB Cooling Strategies Using Thermal Vias

Conclusion: Elevate Your Retail Tech with Thermal Vias

Effective thermal management is non-negotiable in retail technology, where reliability and performance are paramount. Thermal vias offer a practical, efficient solution for heat dissipation PCB challenges, enabling engineers to design compact, cost-effective, and durable hardware. By following best practices in thermal via PCB design—such as optimal placement, proper sizing, and leveraging thermal simulation PCB tools—you can significantly enhance cooling PCB retail hardware.

ALLPCB

ALLPCB