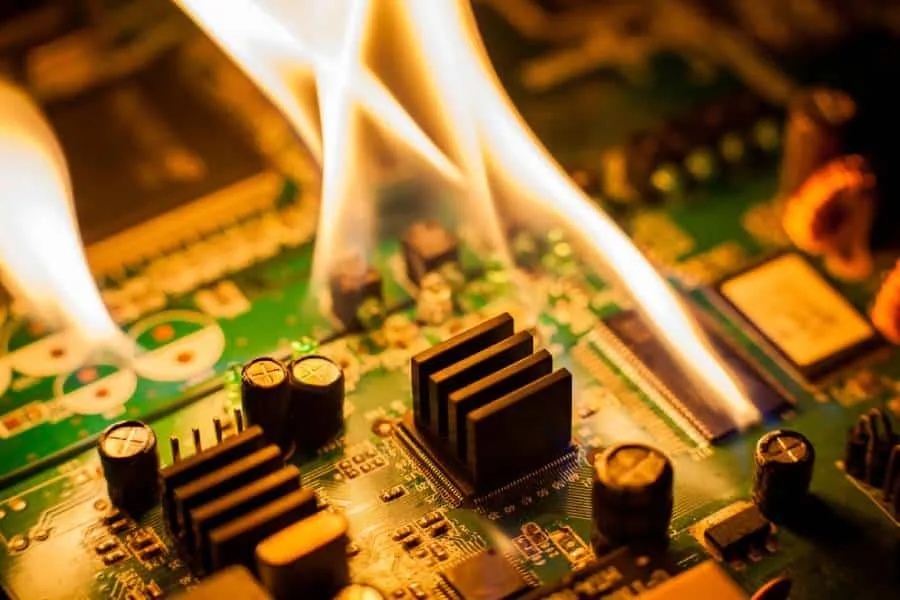

In the demanding world of defense electronics, ensuring the reliability of printed circuit boards (PCBs) is critical. One of the biggest challenges in designing defense PCBs is managing heat effectively. Poor thermal management can lead to component failure, reduced performance, and even system breakdowns in high-stakes environments. So, how can you ensure your defense PCBs stay cool under pressure? The answer lies in adopting proven thermal management strategies like heat dissipation techniques, thermal vias, heat sinks, and tailored designs for high-power PCBs.

In this comprehensive guide, we’ll dive deep into the best practices for defense PCB thermal management. From understanding the unique challenges of defense applications to exploring advanced heat dissipation techniques, this blog will equip you with actionable insights to enhance the reliability and performance of your PCBs. Let’s explore how to keep your designs cool and operational in the toughest conditions.

Why Thermal Management Matters for Defense PCBs

Defense electronics often operate in extreme conditions—think high temperatures in desert deployments, freezing cold in arctic missions, or intense vibrations in aerospace applications. These environments put immense stress on PCBs, especially when paired with the high-power demands of modern defense systems like radar, communication devices, and missile guidance systems. Without effective thermal management, heat buildup can degrade components, disrupt signal integrity, and shorten the lifespan of critical equipment.

For instance, a typical high-power PCB in a defense application might handle currents exceeding 10A or power levels above 50W. If this heat isn’t dissipated properly, temperatures can rise beyond safe limits (often above 85°C for many components), leading to thermal runaway or failure. This makes defense PCB thermal management not just a design consideration, but a mission-critical priority.

Key Challenges in Defense PCB Thermal Management

Before diving into solutions, it’s important to understand the specific challenges that make thermal management for defense PCBs unique:

- High-Power Density: Defense systems often pack significant power into compact designs, leading to concentrated heat in small areas.

- Harsh Environments: Exposure to extreme temperatures, humidity, and shock can exacerbate thermal stress on components.

- Reliability Requirements: Failure is not an option in defense applications, so PCBs must maintain performance over long periods under stress.

- Space Constraints: Limited space for cooling solutions like large heat sinks or fans often restricts design options.

Addressing these challenges requires a combination of innovative design techniques and advanced materials. Let’s explore the most effective heat dissipation techniques for defense PCBs.

Effective Heat Dissipation Techniques for Defense PCBs

Heat dissipation is the cornerstone of thermal management. By efficiently transferring heat away from critical components, you can prevent overheating and ensure long-term reliability. Here are some proven techniques tailored for defense applications:

1. Optimize PCB Layout for Heat Distribution

The layout of your PCB plays a huge role in how heat spreads across the board. A poorly designed layout can create hot spots where heat accumulates, while a well-thought-out design can distribute heat evenly. For defense PCBs, consider these layout tips:

- Place high-power components, such as power transistors or ICs, near the edges of the board or close to heat dissipation paths.

- Use wider copper traces for high-current paths to reduce resistance and minimize heat generation. For example, a trace carrying 5A should ideally be at least 50 mils wide for a 1 oz copper layer to keep temperature rise below 10°C.

- Separate heat-sensitive components from high-heat sources to avoid thermal coupling.

2. Incorporate Thermal Vias for Enhanced Heat Transfer

Thermal vias are small, plated-through holes that act as conduits for heat, transferring it from the top layer of the PCB to the bottom layer or to a ground plane. In high-power defense PCBs, thermal vias are especially effective for components like power amplifiers or LEDs that generate significant heat.

For optimal results, follow these guidelines when using thermal vias:

- Place thermal vias directly under or near heat-generating components to create a short path for heat transfer.

- Use a grid pattern of vias (e.g., a 5x5 array with 0.3mm diameter vias spaced 1mm apart) to maximize heat conduction without compromising structural integrity.

- Connect thermal vias to large copper planes or heat sinks on the opposite side of the board for better heat spreading.

Studies show that thermal vias can reduce component temperatures by up to 20°C in high-power designs, making them a go-to solution for defense PCB thermal management.

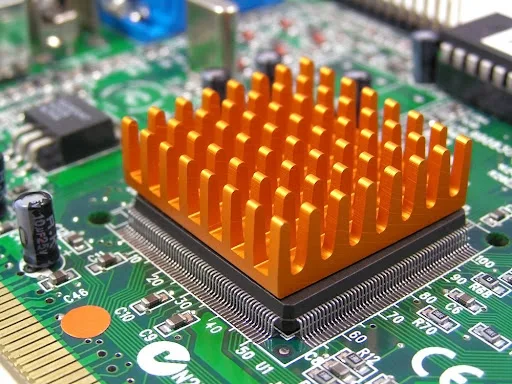

3. Leverage Heat Sinks for High-Power Components

Heat sinks are passive cooling devices that absorb and dissipate heat from components into the surrounding environment. In defense applications, where active cooling like fans may not be feasible due to space or reliability concerns, heat sinks are often the best choice for managing heat in high-power PCBs.

When selecting and integrating heat sinks, consider these factors:

- Choose materials with high thermal conductivity, such as aluminum (thermal conductivity of 205 W/m·K) or copper (401 W/m·K), for maximum heat transfer.

- Ensure proper contact between the heat sink and the component using thermal interface materials (TIMs) like thermal grease or pads to minimize thermal resistance.

- Opt for compact, low-profile heat sinks in space-constrained defense designs to maintain a balance between cooling and size.

For example, a heat sink with a thermal resistance of 2°C/W can keep a 20W power IC within safe operating temperatures (below 85°C) even in ambient conditions of 50°C.

4. Use High-Thermal-Conductivity Materials

The materials used in your PCB can make a big difference in heat dissipation. Standard FR-4 material has a thermal conductivity of about 0.3 W/m·K, which is insufficient for high-power defense applications. Instead, consider advanced substrates like:

- Metal-Core PCBs (MCPCBs): These feature a metal base layer (often aluminum) with thermal conductivity up to 10 W/m·K, ideal for dissipating heat in compact designs.

- Ceramic Substrates: With thermal conductivity ranging from 20 to 170 W/m·K, ceramics are excellent for extreme environments but come at a higher cost.

Switching to a metal-core PCB can reduce board temperatures by 15-30% compared to FR-4, significantly improving reliability in defense systems.

Advanced Thermal Management Strategies for High-Power PCBs

In defense applications, high-power PCBs often require more than basic heat dissipation techniques. Here are advanced strategies to tackle the toughest thermal challenges:

1. Implement Embedded Cooling Solutions

For ultra-high-power designs, consider embedding cooling solutions directly into the PCB structure. Techniques like buried copper coins or integrated heat pipes can provide direct heat paths away from critical components. Copper coins, for instance, are small metal inserts placed under heat-generating components, offering thermal conductivity up to 400 W/m·K.

While these solutions are more complex and costly, they can reduce component temperatures by over 30°C in extreme cases, ensuring reliability in mission-critical defense systems.

2. Utilize Phase Change Materials (PCMs)

Phase Change Materials absorb heat by changing from solid to liquid at a specific temperature, effectively buffering temperature spikes. In defense PCBs, PCMs can be integrated near high-power components to manage transient heat loads, such as those experienced during short bursts of radar operation.

PCMs with melting points around 50-60°C can absorb up to 200 J/g of heat, providing a temporary thermal buffer until steady-state cooling mechanisms take over.

3. Enhance Airflow with Enclosure Design

While active cooling like fans may not always be viable in defense applications, optimizing the enclosure design can improve passive airflow. Strategic vent placement and convection-friendly layouts can help dissipate heat from the PCB to the external environment, especially in ground-based or naval systems where natural airflow is available.

Design Considerations for Long-Term Reliability

Beyond immediate heat dissipation, long-term reliability in defense PCBs requires attention to detail during the design and testing phases:

- Thermal Simulation: Use simulation tools to predict heat distribution and identify potential hot spots before fabrication. Tools can model temperature rises with accuracy within 5°C, helping you refine your design early.

- Component Derating: Operate components below their maximum rated power or temperature (e.g., at 80% of capacity) to reduce thermal stress and extend lifespan.

- Environmental Testing: Test PCBs under conditions mimicking real-world defense scenarios, such as temperature cycling from -40°C to 85°C, to validate thermal performance.

Conclusion: Building Reliable Defense PCBs with Effective Thermal Management

Thermal management is a non-negotiable aspect of designing reliable defense PCBs. By implementing strategies like optimized layouts, thermal vias, heat sinks, and advanced materials, you can tackle the unique challenges of high-power PCBs in harsh environments. Whether you’re working on radar systems, communication devices, or aerospace electronics, effective heat dissipation techniques are key to ensuring performance and longevity.

At ALLPCB, we understand the critical role of defense PCB thermal management in mission success. Our expertise and advanced manufacturing capabilities can help you bring thermally optimized designs to life, no matter the complexity. Start integrating these strategies into your next project to keep your defense electronics cool, reliable, and ready for action.

ALLPCB

ALLPCB