When designing a printed circuit board (PCB), one key decision is whether to use a solder mask or leave the copper exposed. A green solder mask, the most common choice, offers protection and reliability, while opting for no solder mask can save costs in specific scenarios. So, which is right for your project? In this comprehensive guide, we’ll break down the differences between a green solder mask and no solder mask, explore PCB design considerations, and provide a cost-benefit analysis to help you decide. Whether you're concerned about exposed copper PCB risks or seeking the advantages of a green solder mask, we’ve got you covered with practical insights and actionable advice.

What Is a Solder Mask and Why Does It Matter?

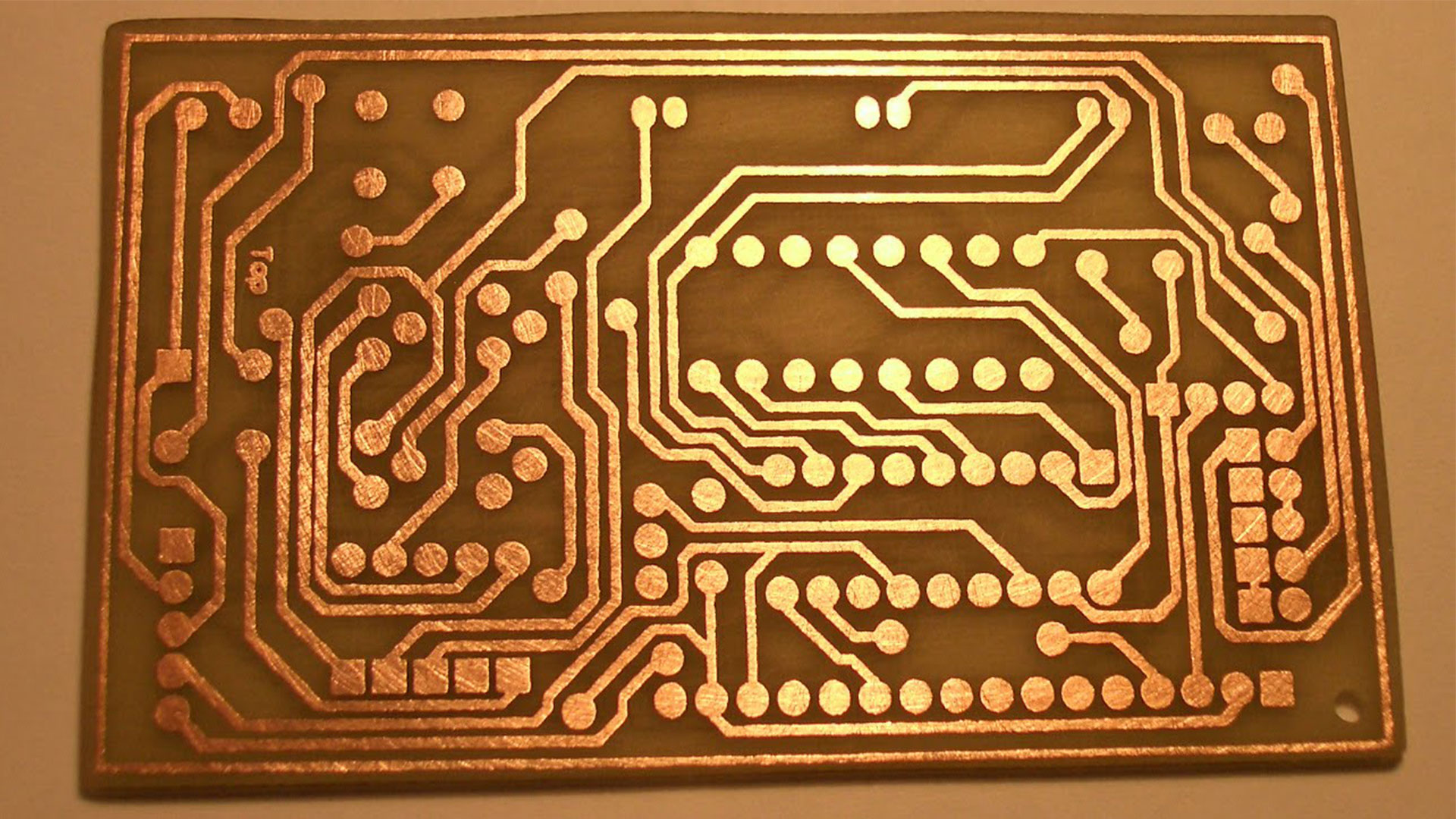

A solder mask, also known as solder resist, is a thin protective layer applied to the copper traces of a PCB. Its primary role is to shield the copper from oxidation, prevent short circuits during soldering, and protect the board from environmental damage like moisture or dust. The green solder mask, in particular, has become an industry standard due to its visibility, cost-effectiveness, and proven reliability.

On the other hand, choosing no solder mask means leaving the copper traces exposed. This can be a deliberate choice in certain low-cost or prototype designs, but it comes with risks like corrosion and unintended solder bridges. Understanding when to use a green solder mask versus skipping it entirely is crucial for balancing performance, durability, and budget in your PCB design.

Green Solder Mask Advantages: Why It’s the Go-To Choice

The green solder mask is widely used in PCB manufacturing for several reasons. Let’s dive into the key benefits that make it a preferred option for most projects.

1. Protection Against Oxidation and Corrosion

Exposed copper on a PCB can oxidize quickly when exposed to air and moisture, leading to degraded performance or complete failure. A green solder mask acts as a barrier, preventing oxidation and extending the lifespan of the board. For instance, in humid environments, a PCB without a solder mask might show signs of corrosion within weeks, while a masked board can last years under the same conditions.

2. Prevention of Solder Bridges

During the soldering process, there’s a risk of solder accidentally connecting adjacent traces, causing short circuits. A green solder mask covers non-soldering areas, ensuring solder only adheres to designated pads. This is especially critical in high-density designs where traces are spaced as close as 0.1 mm apart, and even a tiny solder bridge can ruin functionality.

3. Enhanced Visibility for Inspection

The green color of the solder mask provides high contrast against the copper traces and white silkscreen markings, making it easier to inspect for defects. This visual clarity helps technicians spot issues like misaligned components or soldering errors during quality control. Studies in manufacturing have shown that green masks improve defect detection rates by up to 15% compared to darker or less contrasting colors.

4. Cost-Effective and Widely Available

Green solder mask materials have been used for decades, making them the most affordable and readily available option. The manufacturing process for green masks is well-optimized, often costing 10-20% less than alternative colors due to bulk production and standardized formulas.

5. Thermal and Electrical Insulation

A green solder mask provides a layer of insulation, reducing the risk of electrical interference between traces. It also helps manage thermal stress during soldering, preventing damage to the copper. For high-power applications, this insulation can be critical to maintaining signal integrity and avoiding breakdowns at temperatures exceeding 150°C.

Exposed Copper PCB: When No Solder Mask Makes Sense

While a green solder mask offers clear advantages, there are scenarios where skipping it might be a viable option. Choosing an exposed copper PCB can simplify the manufacturing process and cut costs, but it’s not without trade-offs. Here’s when and why you might consider going without a solder mask.

1. Cost Savings for Prototypes

For early-stage prototypes or one-off designs, omitting the solder mask can reduce production costs by 5-15%. This is because applying a solder mask adds an extra step to the manufacturing process, including material and labor expenses. If you’re testing a simple design with minimal risk of shorts or corrosion, an exposed copper PCB can be a budget-friendly choice.

2. Simplified Manufacturing for Low-Volume Runs

In small-batch production, skipping the solder mask can speed up turnaround time. Without the need for mask application and curing, manufacturers can produce boards faster, sometimes shaving off 1-2 days from the total lead time. This is particularly useful for hobbyists or startups with tight deadlines and limited budgets.

3. Specific Design Requirements

In rare cases, a design may require exposed copper for functional reasons. For example, some RF (radio frequency) circuits or high-current applications might benefit from direct copper exposure to improve heat dissipation or signal performance. However, these cases often require additional protective coatings like ENIG (Electroless Nickel Immersion Gold) to prevent oxidation, which can offset initial cost savings.

Risks of Exposed Copper PCBs

While there are reasons to skip a solder mask, the risks associated with exposed copper are significant. Here are the main drawbacks to consider.

1. Vulnerability to Environmental Damage

Without a solder mask, copper traces are prone to oxidation and corrosion, especially in environments with high humidity or temperature fluctuations. Oxidized copper can increase electrical resistance, leading to signal loss or failure. For example, a board exposed to 80% humidity for just 48 hours can develop visible tarnish, impacting performance.

2. Higher Risk of Short Circuits

During soldering, exposed copper increases the chance of solder bridges forming between closely spaced traces. This risk is particularly high in designs with trace spacing below 0.2 mm, where even a small amount of excess solder can cause a short. Repairing such issues can be costly and time-consuming.

3. Reduced Long-Term Reliability

An exposed copper PCB is less durable over time. Without protection, the board is more susceptible to physical damage, such as scratches that can break traces. This makes it unsuitable for applications requiring long-term reliability, like medical devices or automotive electronics, where failure rates must be below 0.1%.

PCB Design Considerations: Solder Mask vs. No Solder Mask

When deciding between a green solder mask and no solder mask, several PCB design considerations come into play. Evaluating these factors will help ensure your board meets performance, reliability, and budget goals.

1. Application and Environment

Consider where and how the PCB will be used. If it’s for a consumer product exposed to varying temperatures and humidity, a green solder mask is essential for protection. For indoor, controlled environments like a lab prototype, an exposed copper PCB might suffice temporarily.

2. Complexity and Density of Design

High-density designs with fine-pitch components (e.g., BGA packages with 0.4 mm spacing) demand a solder mask to prevent soldering errors. Simpler designs with wider trace spacing (above 0.5 mm) might tolerate exposed copper, though the risk of shorts still exists.

3. Signal Integrity Requirements

For high-speed or RF applications, a solder mask can help maintain signal integrity by reducing crosstalk and interference between traces. Exposed copper, while potentially beneficial for heat dissipation in some cases, can introduce noise if not carefully managed, especially at frequencies above 1 GHz.

4. Manufacturing and Assembly Process

If your PCB will undergo automated assembly with surface-mount components, a solder mask ensures precise solder placement. Manual soldering on an exposed copper board is riskier and often results in a higher defect rate, sometimes as much as 10% more than masked boards.

Cost-Benefit Analysis: Green Solder Mask vs. No Solder Mask

Balancing cost and performance is a critical part of PCB design. Let’s break down the cost-benefit analysis of using a green solder mask versus opting for an exposed copper PCB.

Upfront Costs

Adding a green solder mask typically increases manufacturing costs by 5-15%, depending on the board size and complexity. For a standard 2-layer PCB of 100 mm x 100 mm, this might mean an additional $0.50 to $1.50 per board. For low-budget prototypes or small runs (under 10 units), skipping the mask can save this expense upfront.

Long-Term Savings with Solder Mask

While a green solder mask adds to initial costs, it saves money over time by reducing failures and rework. For example, a board with exposed copper might fail due to corrosion within 6 months, requiring replacement at a cost of $5-10 per unit. A masked board, lasting 2-3 years or more, avoids these recurring expenses. Additionally, fewer soldering defects mean lower assembly costs, with defect rates often dropping from 8% to under 2% with a mask.

Risk of Hidden Costs with Exposed Copper

Choosing no solder mask can lead to unexpected expenses. Corrosion or short circuits might not be evident until after deployment, leading to field failures and costly recalls. For a batch of 1,000 boards, even a 5% failure rate due to exposed copper issues could result in hundreds of dollars in losses, far outweighing the initial savings of skipping the mask.

When to Use Green Solder Mask

Based on the advantages and cost-benefit analysis, a green solder mask is the right choice in most cases. Here are specific scenarios where it’s highly recommended:

- Production Boards: For any PCB intended for final products, a green solder mask ensures reliability and durability.

- Harsh Environments: If the board will be exposed to moisture, dust, or temperature extremes, a mask is non-negotiable.

- High-Density Designs: Complex layouts with tight spacing need a mask to prevent shorts and ensure soldering accuracy.

- Long-Term Use: For applications requiring a lifespan of over 1 year, a solder mask protects against wear and tear.

When to Skip Solder Mask

Skipping the solder mask should be a rare decision, limited to specific situations. Consider it only if:

- Short-Term Prototypes: For quick, disposable test boards where cost is the primary concern.

- Controlled Environments: If the PCB will be used in a dry, indoor setting with no risk of environmental damage.

- Specialized Designs: In cases where exposed copper is necessary for thermal or electrical performance, and alternative coatings are applied.

Conclusion: Making the Right Choice for Your PCB

Deciding between a green solder mask and no solder mask comes down to your project’s specific needs, budget, and long-term goals. A green solder mask offers unmatched protection, reliability, and ease of inspection, making it the ideal choice for most PCB designs. Its advantages, from preventing corrosion to reducing soldering errors, far outweigh the slight upfront cost. However, for very early prototypes or niche applications, an exposed copper PCB can be a temporary, cost-saving alternative if the risks are managed carefully.

By weighing the PCB design considerations and conducting a thorough cost-benefit analysis, you can make an informed decision that ensures your board performs as intended. Whether you prioritize the proven benefits of a green solder mask or opt for the simplicity of exposed copper, understanding the trade-offs is key to successful PCB manufacturing.

ALLPCB

ALLPCB