In the fast-evolving world of portable gaming devices, battery life is a top concern for both designers and gamers. How can you create a portable console that lasts through long gaming sessions without needing a recharge? The answer lies in low power PCB design for gaming. By focusing on efficient power management, optimized voltage regulation, and smart thermal considerations, you can significantly extend playtime. In this blog, we dive deep into portable console battery life optimization, gaming device power management ICs, and other critical strategies to help engineers design power-efficient PCBs for the ultimate gaming experience.

Why Power Efficiency Matters in Portable Gaming Devices

Portable gaming devices, such as handheld consoles, rely heavily on battery power to deliver uninterrupted gameplay. Gamers expect hours of play without the hassle of frequent charging. However, high-performance processors, vibrant displays, and wireless connectivity can quickly drain batteries. This is where low power PCB design for gaming comes into play. A well-designed PCB can minimize energy waste, reduce heat generation, and extend battery life, ensuring gamers stay immersed in their favorite titles.

Beyond user satisfaction, power efficiency also impacts the overall design. Smaller, lighter batteries can be used if power consumption is optimized, making devices more compact and comfortable to hold. Let’s explore the key aspects of designing power-efficient PCBs for portable gaming devices.

Key Strategies for Low Power PCB Design in Gaming

Designing a PCB for low power consumption requires a combination of careful component selection, smart layout planning, and innovative power management techniques. Below, we break down the essential strategies to achieve portable console battery life optimization.

1. Selecting Low-Power Components

The foundation of a power-efficient PCB starts with choosing the right components. Modern microcontrollers and processors designed for low power consumption, such as those based on ARM architecture, are ideal for portable gaming devices. These chips often include power-saving modes like sleep or idle states, which can reduce energy use by up to 80% when the device is not under heavy load.

Additionally, opt for energy-efficient displays and sensors. For example, OLED screens consume less power compared to traditional LCDs when displaying darker colors, which is common in many game interfaces. When selecting memory and storage components, prioritize low-voltage options that operate at 1.8V or lower instead of the standard 3.3V, as this can cut power draw by nearly 40% in some cases.

2. Optimizing PCB Layout for Power Efficiency

The physical layout of a PCB plays a significant role in power efficiency. Poorly designed traces can lead to resistive losses, where energy is wasted as heat. To minimize this, use wider traces for power lines to reduce resistance—aim for trace widths of at least 0.5mm for high-current paths. Keep power and ground planes close together to lower impedance, targeting values below 0.1 ohms for critical paths.

Another tip is to place high-power components, like GPUs and CPUs, near the power source to shorten trace lengths. This reduces voltage drops, ensuring stable power delivery. A well-optimized layout can improve power efficiency by 10-15%, directly contributing to extended battery life in portable gaming devices.

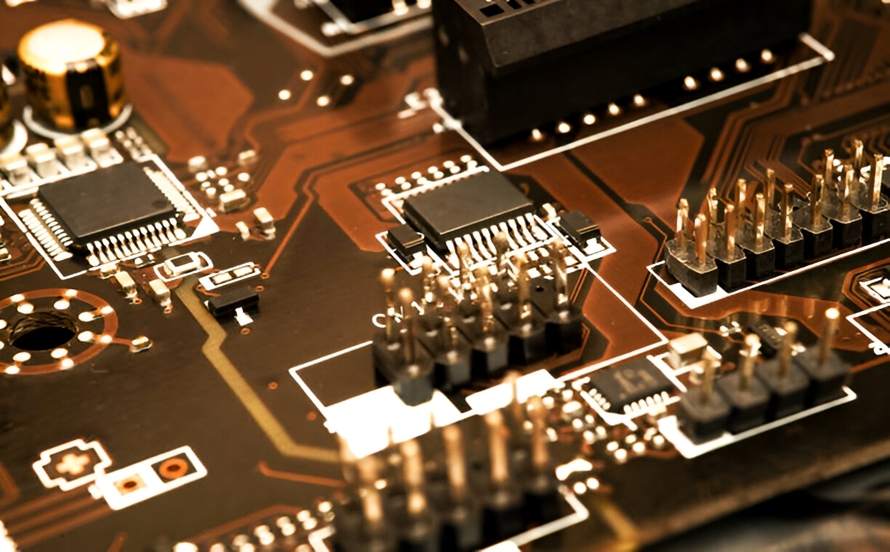

Gaming Device Power Management ICs: The Heart of Efficiency

Power management integrated circuits (PMICs) are critical for controlling how energy is distributed and consumed in a portable gaming device. These chips handle tasks like voltage regulation, battery charging, and power mode switching, making them indispensable for portable console battery life optimization.

Choosing the Right PMIC

A good PMIC for gaming devices should support multiple output rails to power different components at their optimal voltage levels. For instance, a processor might require 1.2V, while a display needs 3.3V. Using a PMIC with dynamic voltage scaling can adjust these levels in real-time, reducing power waste by up to 30% during low-demand scenarios like menu navigation.

Look for PMICs with high efficiency ratings, ideally above 90%, especially for buck and boost converters. These converters step down or step up voltages with minimal energy loss, ensuring more power reaches the components instead of being lost as heat.

Implementing Power-Saving Modes

Many PMICs support power-saving modes that can shut down unused circuits or lower voltage during idle periods. For example, when a game is paused, the PMIC can reduce the GPU’s power draw by switching to a low-power state, saving 20-50% of energy depending on the workload. Integrating these features into your PCB design ensures the device only uses the power it needs at any given moment.

Efficient Voltage Regulation in PCB Design

Voltage regulation is a cornerstone of power-efficient PCB design for portable gaming devices. Poor regulation can lead to energy waste, overheating, and even component damage. Let’s look at how to achieve efficient voltage regulation in PCB design.

Switching Regulators vs. Linear Regulators

Switching regulators, such as buck converters, are far more efficient than linear regulators for stepping down voltage. While linear regulators might have efficiencies as low as 50%, switching regulators can achieve efficiencies of 85-95%. This means less power is lost as heat, directly benefiting battery life. For a gaming device drawing 2A at 3.3V, switching to a high-efficiency regulator could save over 1W of power compared to a linear option.

However, switching regulators introduce noise, which can interfere with sensitive components like audio circuits. To mitigate this, place decoupling capacitors (typically 0.1μF to 1μF) near the regulator output and use proper grounding techniques to keep noise levels below 50mV peak-to-peak.

Minimizing Voltage Drops

Voltage drops across traces and components can reduce efficiency and affect performance. Aim to keep voltage drops below 100mV for critical power paths by using low-resistance materials and optimizing trace lengths. For high-current areas, consider multilayer PCBs with dedicated power planes to maintain stable voltage delivery across the board.

Thermal Considerations for Portable Gaming PCBs

Heat is the enemy of both performance and battery life in portable gaming devices. Excessive heat can cause components to throttle, reducing gameplay quality, and it accelerates battery degradation. Addressing thermal considerations for portable gaming PCBs is essential for maintaining efficiency and user comfort.

Heat Dissipation Techniques

Start by placing heat-generating components, such as CPUs and GPUs, away from sensitive areas like batteries. Use thermal vias—small holes filled with conductive material—to transfer heat from the top layer of the PCB to a bottom copper plane, where it can dissipate more effectively. A typical design might include 10-20 vias under a high-power chip, reducing its operating temperature by 5-10°C.

Incorporate heat sinks or thermal pads for major heat sources if space allows. Even a small heat sink can lower GPU temperatures by 15°C under heavy load, preventing thermal throttling and maintaining consistent performance during intense gaming sessions.

Material Selection for Thermal Management

The choice of PCB material also impacts heat dissipation. Standard FR-4 material has a thermal conductivity of about 0.3 W/mK, which is adequate for low-power designs but insufficient for gaming devices. Consider high-thermal-conductivity laminates with values of 1.0 W/mK or higher to improve heat spreading. While these materials may increase costs by 20-30%, they can extend component lifespan and improve overall device reliability.

Balancing Power Efficiency with Performance

While power efficiency is crucial, portable gaming devices must still deliver high performance to meet user expectations. Striking the right balance involves leveraging adaptive power management techniques. For instance, dynamic frequency scaling allows the CPU and GPU to ramp up during demanding game scenes and scale back during lighter tasks, saving up to 25% of power without noticeable lag.

Software optimization also plays a role. Collaborate with firmware developers to implement algorithms that predict workload and adjust power settings accordingly. This synergy between hardware and software can push battery life gains even further, sometimes adding an extra hour of playtime on a single charge.

Testing and Validation for Power Efficiency

Once the PCB design is complete, rigorous testing is necessary to ensure power efficiency goals are met. Use power profiling tools to measure consumption across different scenarios, such as idle, menu navigation, and full gameplay. Aim for idle power draw below 100mW and ensure peak draw doesn’t exceed battery or PMIC limits—typically around 5-10W for most handheld devices.

Thermal imaging cameras can help identify hot spots on the PCB, allowing you to tweak layouts or add cooling solutions before mass production. Validate battery life under real-world conditions, targeting at least 6-8 hours of continuous gameplay for a competitive edge in the portable gaming market.

Conclusion: Powering the Future of Portable Gaming

Designing power-efficient PCBs for portable gaming devices is a complex but rewarding challenge. By focusing on low power PCB design for gaming, leveraging advanced gaming device power management ICs, ensuring efficient voltage regulation in PCB design, and addressing thermal considerations for portable gaming PCBs, engineers can create devices that offer extended playtime without sacrificing performance. These strategies not only enhance user experience but also push the boundaries of what portable consoles can achieve.

At ALLPCB, we’re committed to supporting innovators in bringing their gaming device designs to life with high-quality PCB manufacturing solutions. Whether you’re optimizing for portable console battery life or tackling thermal challenges, our expertise can help you build the next generation of gaming hardware.

ALLPCB

ALLPCB