In the fast-evolving world of construction machinery, integrating embedded systems into printed circuit boards (PCBs) has become a game-changer. These systems enable real-time control, monitoring, and automation, enhancing efficiency and safety on job sites. However, combining PCB embedded systems with construction machinery comes with unique challenges, from harsh environmental conditions to complex real-time data processing needs. In this blog, we’ll explore how embedded systems are integrated into construction machinery PCBs, the benefits they bring, and the obstacles engineers face in this process. Let’s dive into the details of PCB embedded systems, construction machinery integration, and real-time PCB challenges.

What Are Embedded Systems in Construction Machinery PCBs?

Embedded systems are specialized computer systems designed to perform specific tasks within a larger mechanical or electrical system. In the context of construction machinery, these systems are often integrated directly into PCBs to control functions like engine management, hydraulic systems, and operator interfaces. Unlike general-purpose computers, embedded systems are optimized for efficiency, low power consumption, and real-time response.

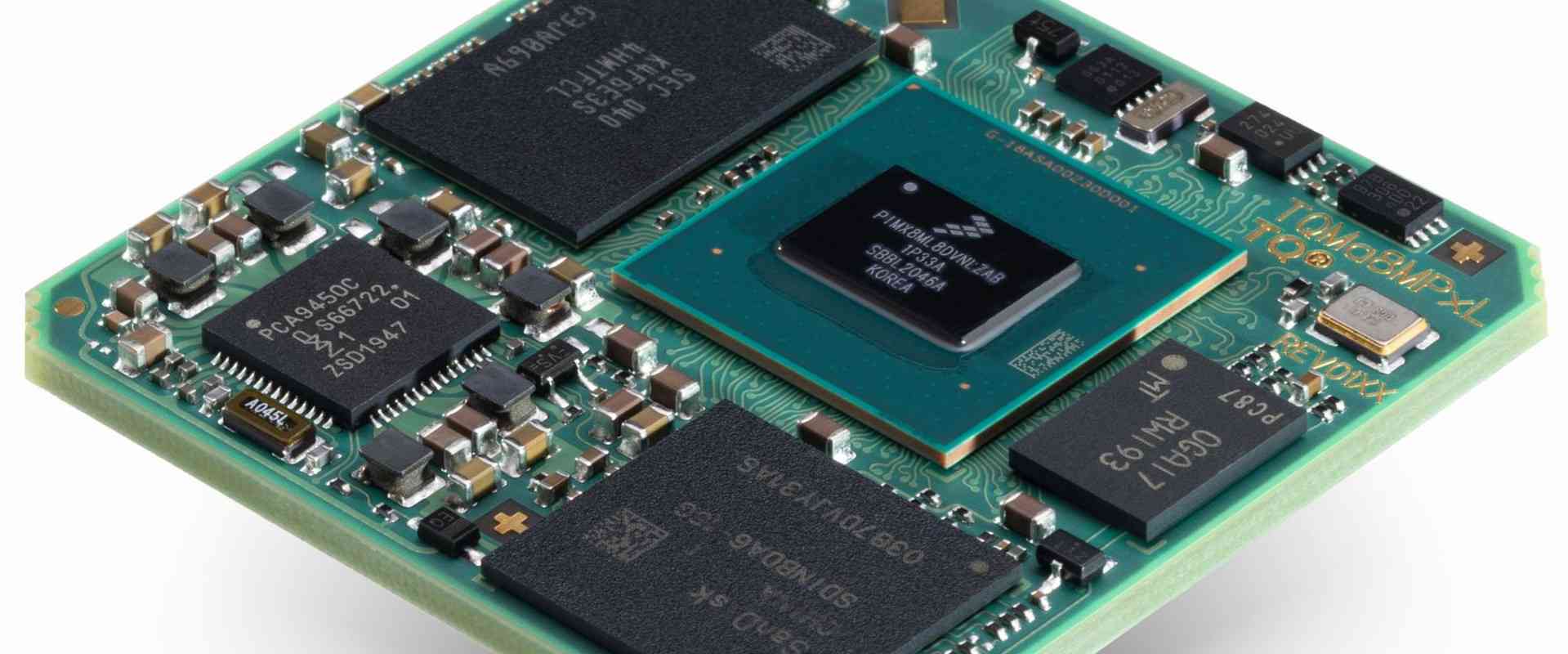

On a PCB, embedded systems typically consist of microcontrollers or microprocessors, memory units, and input/output interfaces, all working together to process data and execute commands. For example, in an excavator, an embedded system on a PCB might monitor hydraulic pressure in real time, ensuring the arm moves with precision. These systems often operate at signal speeds of up to 100 MHz or higher, depending on the complexity of the machinery, and must maintain low impedance values—often below 50 ohms—for reliable signal integrity.

The Importance of PCB Embedded Systems in Construction Machinery

Construction machinery, such as bulldozers, cranes, and loaders, operates in demanding environments where precision and reliability are critical. Integrating embedded systems into PCBs offers several key benefits:

- Real-Time Control: Embedded systems allow machinery to respond instantly to operator inputs or sensor data. For instance, a real-time PCB in a crane can adjust load balance within milliseconds to prevent tipping.

- Automation: These systems enable automated features, such as GPS-guided earthmoving, reducing human error and boosting productivity by up to 30% in some studies.

- Diagnostics and Maintenance: Embedded systems can monitor machinery health, detecting issues like overheating or wear in components before they lead to costly breakdowns.

- Safety: By integrating sensors and control logic, embedded PCBs help prevent accidents, such as automatically stopping a machine if an obstacle is detected.

With the rise of smart construction sites, the demand for advanced PCB embedded systems is growing. By 2025, the global market for smart construction equipment is expected to reach significant milestones, driven by the need for efficiency and data-driven decision-making.

How Are Embedded Systems Integrated into Construction Machinery PCBs?

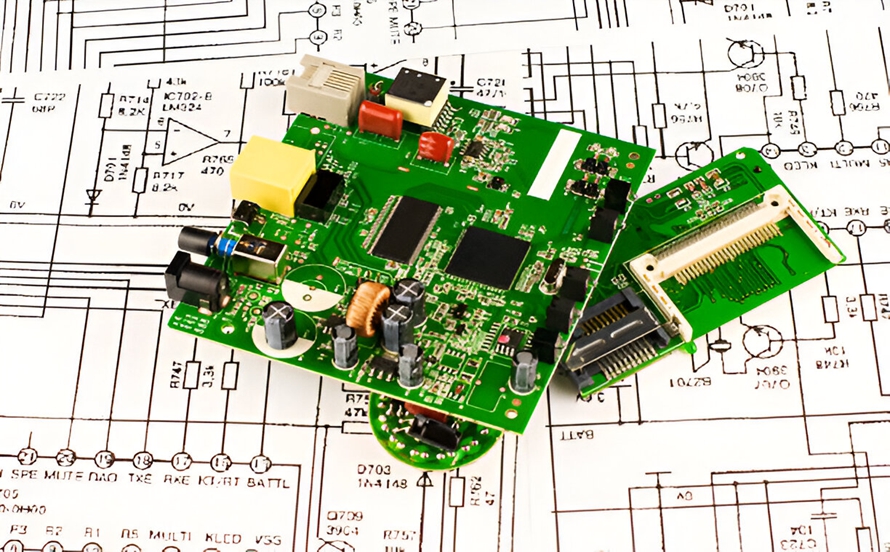

Integrating embedded systems into PCBs for construction machinery is a multi-step process that requires careful planning and execution. Here’s a breakdown of the key stages:

1. System Design and Specification

The first step is defining the requirements of the embedded system. Engineers determine the necessary processing power, memory, and input/output capabilities based on the machinery’s functions. For example, a loader might need a system capable of handling multiple sensor inputs at a data rate of 1 Mbps to monitor load weight and hydraulic pressure.

2. PCB Layout and Component Selection

Once the system is designed, the PCB layout is created to accommodate the embedded components. This includes selecting microcontrollers with operating voltages as low as 3.3V for power efficiency and ensuring trace impedance is controlled—often around 50 ohms—to minimize signal loss. Components are chosen for their durability, as construction machinery PCBs must withstand vibration and temperature swings from -40°C to 85°C.

3. Firmware Development

The embedded system’s firmware is programmed to handle specific tasks, such as real-time data processing or communication with other systems via protocols like CAN bus, which operates at speeds up to 1 Mbps. This software must be optimized to ensure minimal latency, often achieving response times under 10 microseconds for critical operations.

4. Testing and Validation

Before deployment, the PCB undergoes rigorous testing to ensure reliability under harsh conditions. This includes vibration tests simulating up to 10G of force and thermal cycling to verify performance across extreme temperatures. Only after passing these tests is the PCB integrated into the machinery.

Key Challenges in Integrating Embedded Systems into Construction Machinery PCBs

While the benefits of PCB embedded systems in construction machinery are clear, the integration process is not without challenges. Below are some of the most significant hurdles engineers face when working on real-time PCB solutions for heavy equipment.

1. Harsh Environmental Conditions

Construction machinery operates in extreme conditions, including dust, moisture, and temperature fluctuations. These factors can degrade PCB components over time, leading to failures. For instance, high humidity can cause corrosion on PCB traces, while vibrations at frequencies up to 200 Hz can loosen solder joints. To combat this, engineers use conformal coatings with dielectric strengths of over 1000V/mil and design PCBs with reinforced mounting points to handle mechanical stress.

2. Real-Time Processing Demands

Real-time PCB applications require instantaneous data processing to ensure machinery operates safely and efficiently. A delay of even 50 milliseconds in a system controlling a crane’s load could result in a dangerous situation. Achieving such low latency requires high-speed microcontrollers and optimized firmware, which can increase design complexity and cost.

3. Power Efficiency and Heat Management

Construction machinery often relies on battery power or limited energy sources, making power efficiency critical. Embedded systems must operate at low power—often under 1W for smaller controllers—while still delivering high performance. Additionally, heat dissipation is a challenge, as components packed tightly on a PCB can reach temperatures above 100°C without proper cooling. Engineers address this by using heat sinks and designing layouts with thermal vias to channel heat away from critical areas.

4. Signal Integrity and Electromagnetic Interference (EMI)

Maintaining signal integrity on a PCB is crucial, especially in noisy environments like construction sites where motors and radios generate EMI. Poor signal integrity can lead to data errors, with signal noise levels sometimes exceeding 100 mV. To mitigate this, PCBs are designed with ground planes and shielding, ensuring impedance matching within a tolerance of ±10% to prevent reflections and crosstalk.

5. Size and Weight Constraints

Construction machinery often has limited space for electronics, requiring compact PCB designs. Miniaturization, while beneficial, can complicate heat dissipation and increase the risk of interference between components. High-density interconnect (HDI) technology is often used, allowing for layer counts of 8 or more in a board as small as 50 mm x 50 mm, but this adds to manufacturing complexity and cost.

Solutions to Overcome Integration Challenges

Addressing the challenges of integrating embedded systems into construction machinery PCBs requires innovative approaches and advanced technologies. Here are some practical solutions:

- Robust Materials: Use PCB substrates like FR-4 with high glass transition temperatures (Tg) of 170°C or more to withstand heat and mechanical stress. Components rated for industrial temperature ranges are also essential.

- Advanced Simulation Tools: Leverage simulation software to model signal integrity and thermal performance before manufacturing. This can reduce design iterations by up to 40%, saving time and cost.

- Modular Design: Create modular PCBs that allow for easy replacement or upgrades of embedded systems without redesigning the entire board. This approach can cut maintenance costs by 20% or more.

- EMI Shielding: Incorporate shielding cans and ferrite beads to reduce EMI, ensuring clean signals even in high-noise environments. This can lower error rates by as much as 50% in some setups.

- Real-Time Optimization: Optimize firmware with interrupt-driven architectures to prioritize critical tasks, achieving response times below 5 microseconds for high-priority operations.

Future Trends in PCB Embedded Systems for Construction Machinery

As technology advances, the integration of embedded systems into construction machinery PCBs is set to evolve. Based on current industry insights, here are some trends to watch:

- IoT Connectivity: More machinery will feature IoT-enabled PCBs, allowing for remote monitoring and predictive maintenance via cloud platforms. This could reduce downtime by up to 25%.

- AI Integration: Artificial intelligence is being embedded into PCBs to enable smarter decision-making, such as optimizing fuel efficiency or detecting anomalies in real time.

- Flexible and Wearable Electronics: Flexible PCBs are gaining traction for applications in operator wearables or machinery with complex geometries, offering new ways to integrate embedded systems.

Conclusion

Integrating embedded systems into PCBs for construction machinery is transforming the industry, enabling real-time control, automation, and enhanced safety. However, the process comes with significant challenges, including harsh environmental conditions, real-time processing demands, and signal integrity issues. By leveraging robust materials, advanced design tools, and innovative solutions, engineers can overcome these obstacles and build reliable, efficient systems.

At ALLPCB, we understand the complexities of designing and manufacturing PCBs for demanding applications like construction machinery. Our expertise in high-quality PCB fabrication ensures that your embedded systems perform flawlessly, even in the toughest conditions. Whether you’re tackling construction machinery integration or exploring real-time PCB solutions, we’re here to support your next project with precision and reliability.

ALLPCB

ALLPCB