Conformal coating plays a vital role in enhancing creepage distance on printed circuit boards (PCBs), offering protection against environmental factors and improving electrical insulation. By applying a thin, protective layer over a PCB, conformal coating helps prevent electrical failures caused by moisture, dust, and contamination, while also increasing the creepage distance—the shortest path along the surface between two conductive parts. This blog post dives deep into how conformal coating contributes to creepage distance improvement, why it matters for PCB design, and practical ways to apply it for optimal results. Let’s explore the significance of PCB conformal coating and its impact on performance and safety with ALLPCB.

What Are Creepage Distance and Conformal Coating?

Before we dive into the relationship between conformal coating and creepage distance, let’s clarify these two essential concepts in PCB design. Creepage distance refers to the shortest path along the surface of an insulating material between two conductive elements, such as traces or pads on a PCB. It is a critical factor in high-voltage designs because insufficient creepage distance can lead to electrical arcing or breakdown, risking damage or safety hazards.

Conformal coating, on the other hand, is a thin protective film applied to a PCB after assembly. Typically made from materials like acrylic, silicone, or polyurethane, this coating shields the board from environmental stressors such as moisture, dust, chemicals, and temperature extremes. Beyond protection, conformal coating can enhance the insulating properties of the PCB surface, effectively increasing the creepage distance by reducing the risk of conductive paths forming due to contamination.

Why Creepage Distance Matters in PCB Design

Creepage distance is a fundamental consideration in PCB design, especially for applications involving high voltages or harsh environments. Standards like IEC 60950 and IPC-2221 define minimum creepage distances based on factors such as voltage levels, pollution degree (environmental contamination), and material properties. For instance, in a pollution degree 3 environment (like industrial or outdoor settings), a creepage distance of at least 8 mm might be required for a 500V system to prevent arcing.

Insufficient creepage distance can lead to catastrophic failures. When contaminants like dust or moisture settle on a PCB, they can create unintended conductive paths, reducing the effective creepage distance. This increases the risk of electrical shorts or arcs, which can damage components or cause fires. Enhancing creepage distance through design techniques and protective measures like conformal coating is essential for ensuring reliability and safety.

How Conformal Coating Improves Creepage Distance

Conformal coating acts as a barrier that enhances the insulating properties of a PCB’s surface, directly impacting creepage distance. Here’s how it works:

- Prevents Contamination: Moisture, dust, and other contaminants can lower the surface resistance of a PCB, creating paths for current to flow. Conformal coating seals the board, preventing these materials from settling on the surface and maintaining the intended creepage distance.

- Increases Dielectric Strength: The coating material typically has a high dielectric strength, meaning it can withstand higher voltages without breaking down. For example, silicone-based coatings can offer dielectric strengths of up to 500 V/mil, significantly improving insulation between conductive traces.

- Reduces Carbonization Risk: If an arc occurs, it can burn the PCB surface, leaving a carbonized path that conducts electricity and shortens creepage distance. Conformal coating minimizes this risk by protecting the surface from such damage.

By applying conformal coating, designers can achieve creepage distance improvement without necessarily increasing the physical spacing between components. This is especially valuable in compact, high-density PCB layouts where space is limited.

Types of Conformal Coatings for Creepage Distance Improvement

Not all conformal coatings are created equal. The choice of coating material impacts how effectively it enhances creepage distance and protects the PCB. Here are the most common types:

- Acrylic: Easy to apply and remove, acrylic coatings offer good moisture resistance and moderate dielectric strength (around 300-400 V/mil). They are ideal for general-purpose applications but may not withstand extreme temperatures.

- Silicone: Known for high dielectric strength (up to 500 V/mil) and flexibility, silicone coatings are excellent for high-voltage PCBs and harsh environments. They also resist temperatures up to 200°C, making them suitable for industrial applications.

- Polyurethane: This type provides strong chemical resistance and durability, with dielectric strengths of about 350 V/mil. It’s often used in environments with exposure to solvents or abrasives.

- Epoxy: Offering robust protection and high dielectric strength (around 400 V/mil), epoxy coatings are more rigid and suited for extreme conditions, though they are harder to rework.

Selecting the right conformal coating depends on the specific requirements of your PCB design, including voltage levels, environmental conditions, and budget constraints. For creepage distance improvement in high-voltage designs, silicone or polyurethane coatings are often preferred due to their superior insulation properties.

Application Techniques for PCB Conformal Coating

The effectiveness of conformal coating in enhancing creepage distance largely depends on how it’s applied. Uneven or incomplete coverage can leave vulnerable areas exposed, negating the benefits. Here are common application methods:

- Brushing: A manual method suitable for small-scale production or rework. It allows precise application but risks uneven thickness, which can affect insulation performance.

- Spraying: Using aerosol cans or spray guns, this method is fast and works well for larger batches. However, it may struggle to coat under components or in tight spaces, potentially missing critical areas for creepage protection.

- Dipping: The PCB is submerged in the coating material, ensuring complete coverage. This method is effective for uniform application but can be messy and may require masking of connectors or sensitive areas.

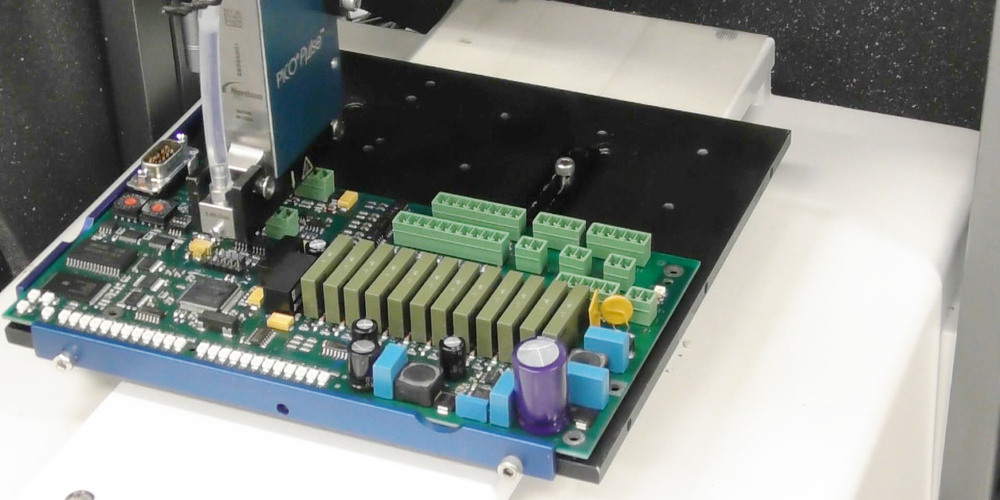

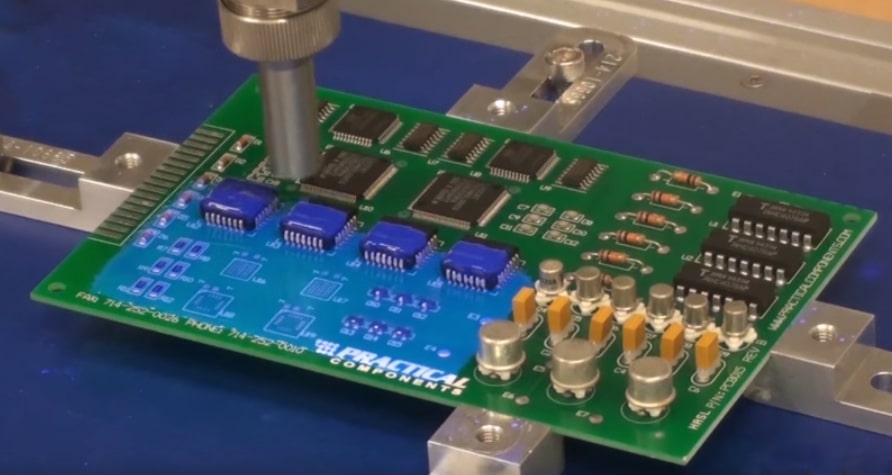

- Selective Coating: Automated machines apply coating only to specific areas, avoiding components like connectors or test points. This method offers precision and is ideal for complex boards where creepage distance needs targeted enhancement.

For best results, ensure the PCB is clean and free of contaminants before applying the coating. Even a thin layer of dust or grease can prevent proper adhesion, reducing the coating’s ability to improve creepage distance. Curing the coating—whether through air drying, heat, or UV light—also plays a critical role in achieving optimal insulation properties.

Additional Design Tips for Creepage Distance Enhancement

While conformal coating is a powerful tool for improving creepage distance, it’s most effective when combined with thoughtful PCB design practices. Here are some complementary strategies:

- Increase Physical Spacing: Where possible, design the PCB layout with wider spacing between high-voltage traces. For example, adhering to IPC-2221 standards might require a 2.5 mm creepage distance for a 250V system in a pollution degree 2 environment.

- Use Slots or Barriers: Adding physical slots or barriers in the PCB material between conductive elements can extend the creepage path. This is particularly useful in compact designs where spacing is limited.

- Choose High-CTI Materials: Select PCB substrates with a high Comparative Tracking Index (CTI), which measures resistance to surface tracking. Materials with a CTI above 600 are less likely to form conductive paths under stress, complementing the effects of conformal coating.

- Avoid Sharp Edges: Rounded corners on traces and pads reduce the risk of electrical discharge, supporting the coating’s protective role.

By integrating these design techniques with conformal coating, you can maximize creepage distance and ensure long-term reliability in challenging environments.

Challenges and Considerations in Using Conformal Coating

While conformal coating offers significant benefits for creepage distance improvement, it’s not without challenges. Understanding these limitations can help you make informed decisions during PCB design and PCB assembly:

- Coverage Issues: Areas under components or in tight spaces may not receive adequate coating, leaving gaps in protection. Using dipping or selective coating methods can mitigate this issue.

- Rework Difficulties: Some coatings, like epoxy, are hard to remove for repairs. Choose a reworkable coating like acrylic if frequent modifications are expected.

- Thermal Expansion: Mismatched thermal expansion between the coating and PCB materials can cause cracking or delamination over time, especially in high-temperature applications. Silicone coatings, with their flexibility, often perform better in such scenarios.

- Cost: High-performance coatings and automated application processes can add to the custom PCB cost. Balance the benefits of creepage distance enhancement with budget constraints.

Addressing these challenges during the planning stage ensures that conformal coating delivers the desired results without introducing new risks to the PCB’s performance.

Real-World Applications of Conformal Coating for Creepage Distance

Conformal coating is widely used across industries where creepage distance is critical to safety and reliability. In automotive electronics, for instance, PCBs in electric vehicles often operate at voltages above 400V, requiring strict creepage distances to prevent arcing. Conformal coating protects these boards from moisture and road contaminants, ensuring consistent performance.

In industrial settings, such as power converters or motor drives, high-voltage PCBs are exposed to dust and humidity. Here, coatings with high dielectric strength, like silicone, help maintain creepage distances of 8 mm or more, as mandated by standards for 500V systems. Similarly, in aerospace and medical devices, where reliability is non-negotiable, conformal coating safeguards against environmental stress while supporting compact designs with tight trace spacing.

Suggested Reading:Automotive PCBA Conformal Coating Standards

Conclusion: Maximizing PCB Reliability with Conformal Coating

Conformal coating is a game-changer in PCB design, offering a practical solution for enhancing creepage distance and protecting against environmental hazards. By acting as an insulating barrier, it prevents contamination, boosts dielectric strength, and reduces the risk of electrical failures, all while supporting compact, high-density layouts. Whether you’re working on automotive, industrial, or consumer electronics, integrating PCB conformal coating into your design process can significantly improve reliability and safety.

Remember to choose the right coating material based on your application’s voltage, environmental, and thermal requirements. Combine this with smart design practices like increased spacing, slots, and high-CTI materials for optimal creepage distance improvement. With the right approach, conformal coating can be a powerful tool to ensure your PCBs perform flawlessly, even under the toughest conditions.

ALLPCB

ALLPCB